MOTAN-COLORTRONIC GMBH

Germany

Manufacturer/ Producer

MOTAN-COLORTRONIC GMBH

Germany

With the METROFLOW gravimetric material loader, plastic processors can automate important areas of the production process cost-effectively and efficiently. The METROFLOW weighs every single load and evaluates the results, with a guaranteed precision of <1%. This improves the entire material management process and allows for full traceability. The material loaders come in 6, 10 and 30 liter volumes. The METROFLOW series is part of the motan range of products and systems for all stages of management, conditioning and preparation of plastic granules. The design quality, plus the engineering, ensures high performance and reliable operation.

Request for a quote

MOTAN-COLORTRONIC GMBH

Germany

motan’s material coupling stations assure that every desired connection of a material to a processing machine in your production process can be made quickly and reliably without contamination. METROCONNECT U: a manually operated un-coded coupling table. METROCONNECT C: a manually operated coded coupling table utilising state-of-the-art wireless RFID technology.

Request for a quote

MOTAN-COLORTRONIC GMBH

Germany

motan’s material selection stations assure that every desired connection of a material to a processing machine in your production process can be made quickly and reliably without contamination. Fixed pipe connections throughout the whole production process until the next material change ensures maximum security. METROLINK: the most advanced fully automatic material selection and distribution system.

Request for a quote

MOTAN-COLORTRONIC GMBH

Germany

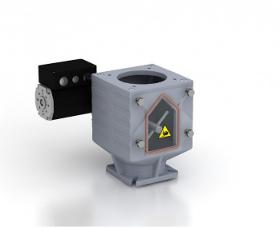

Metal separators from motan can be installed at various locations in a production and for multiple applications. The metal separators prevent damage to your processing machine, tooling and end-products

Request for a quote

MOTAN-COLORTRONIC GMBH

Germany

In the plastics compounding and manufacturing process there are many powders (all with different flow properties) which require handling. For the vacuum conveying of both free-flowing and non-free-flowing powders, motan has a solution. The METRO P series of hopper loaders are available in two versions and guarantee reliable and dust-free conveying. The METRO PC system loaders are designed to be integrated into centralised motan conveying systems. The METRO PB single loaders are designed to be used as a “stand-alone” solution. From the material source right through to the point of processing, motan offers the ideal solution for your powder handling requirements.

Request for a quote

MOTAN-COLORTRONIC GMBH

Germany

Alarms of all systems connected to the motan CONTROLnet can be centrally and mobile monitored with little effort. In addition to the ALARMcollector, this only requires an internet-enabled device with one of the usual browsers. — Collects alarms and messages — Display in a central alarm list (via browser) — Sorting and filtering of alarm information — Connection of external signal devices possible — "Horn-off" function — Language selection (21 languages, incl. CN, RU, AR)

Request for a quote

MOTAN-COLORTRONIC GMBH

Germany

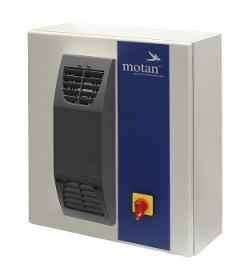

motan offers a compact maintenance box for remote access via internet or company-internal intranet. The box is available as a standardised, ready-to-use system and includes a comprehensive software package for finding and analysing errors within system components as well as for monitoring and documenting system statuses. — Provides remote access to all motan CONTROLnet controls — Prevents unnecessary on-site service operations — Easy installation and compact design — Maintenance-free setup — Easy access via the Internet

Request for a quote

MOTAN-COLORTRONIC GMBH

Germany

For many dosing applications, it is necessary to homogeneously mix different materials of varying bulk densities and flow characteristics. The mixer module 2l is designed for mounting under a dosing unit, where it will mechanically mix, for example a powder additive with virgin material. Further possible uses: Homogenous mixing of virgin material and regrind or with masterbatch or additives. motan has 3 versions available: — Mixer module 2l-MB for MINIBLEND V — Mixer module 2l-MC for MINICOLOR V / G — Mixer module 2l-Uni for universal applications and third-party products

Request for a quote

MOTAN-COLORTRONIC GMBH

Germany

Cost-effective and efficient material conveying can be realized with METRO swift HOS material loaders. This improves the overall process management of your system. The plastic granules are transported quickly and cleanly into hoppers, drying bin or other dosing and mixing units and fed to the machine as required. This eliminates material wastage and keeps the work-space clean and safe.

Request for a quote

MOTAN-COLORTRONIC GMBH

Germany

The three-phase conveying station can be used for a wide range of central conveying applications with a large choice of blower sizes. The three-phase blower is low-noise and maintenance-free. The station is available with a blower protection filter or optionally a cyclone dust filter with collection bin. The integrated VAC swift control is equipped with a 7“colour display which can operate up to 8 METRO swift HOS material loaders and up to 8 purging valves.

Request for a quoteManufacturer/ Producer

Otto-Hahn-Straße 14

61381 Friedrichsdorf - Germany

europages also recommends

A selection of companies related to the activity:

A selection of products that might interest you

SCHOCK GROUP

Germany

Precision in toolmaking is crucial for the quality of your products. Our experienced mold-making team manufactures your tools professionally and functionally. Your project is in the best hands at SCHOCK. Our experienced engineers plan all resources with the most modern methods and guarantee on-time production. Furthermore, we provide full lifecycle support for your tools. In mold and toolmaking, we utilize high-quality milling machines, wire and sinker EDM machines, as well as modern CNC-controlled grinding machines. Our service offerings in the field of injection mold tooling include, among others: Injection molds Multi-component molds (rotary tables, index plates, core-back, transfer technology) Insert technology Gas internal pressure (GID) Foil overmolding (IMD) Thermoset molds Prototype and small-series molds Injection molds: up to 1,000 x 800 mm and 2.5 tons Multi-component molds: rotary tables, index plates, core-back, transfer technology

Request for a quote

ZS INDUSTRIES CO., LTD

China

Material: POM, PP, PA, PE, ABS Process: Injection molding Precision machining Extrusion Application: Agricultural machinery General machinery

Request for a quote

MICRON AMERICA

Turkey

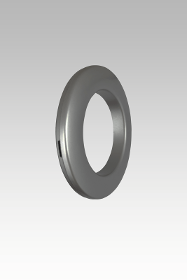

Micron Brand Inc. Heavy Duty #15 Plastic grommets offer a 17/8″ hole size after setting and are made from durable plastic material. Micron Brand Plastic Grommets comes with various color options. Our Grommets are suitable for various fabrics up to a thickness of 4 mm by adjustable distance between the grommets halves

Request for a quote

MICRON AMERICA

Turkey

Micron Brand Inc. Heavy Duty #15 Plastic grommets offer a 17/8″ hole size after setting and are made from durable plastic material. Micron Brand Plastic Grommets comes with various color options. Our Grommets are suitable for various fabrics up to a thickness of 4 mm by adjustable distance between the grommets halves.

Request for a quoteRequest for quotes

Create one request and get multiple quotes form verified suppliers.

- Only relevant suppliers

- Data privacy compliant

- 100% free