- europages

- >

- Boilerwork

- >

- MÜLLER GMBH

- >

- products

MÜLLER GMBH

Germany

Manufacturer/ Producer

MÜLLER GMBH

Germany

Modular process equipment from Müller With the modular process equipment from Müller you can build shells and housings in stainless steel with a diameter from 120 mm to 1200 mm to meet the requirements of your industrial process equipment. This modular system offers a variety of possibilities. All parts are connected with a simple although tight clamp ring connection. Filters - vessels for dust filters, activated carbon, biogas or flue gas filters versatile and variable construction customized for your application simple, cost-effective solutions Vacuum conveying - components for efficient vacuum conveying systems The modular system for your vacuum conveyers: tray inserts hopper inserts filter plates sieve inserts butterfly valves etc. Dryers - vessels with additional insulation The drum as basic module plus appropriate additional modules becomes a drying vessel. This modular system enables a gentle product treatment to be achieved. Scrubbers - vessels for air and water...

Request for a quote

MÜLLER GMBH

Germany

Step 1: Filling Insert plunger Fill product into drum Step 2: Storage Storage Transportation to filling line Step 3: Preperation Special emptying lid placed over drum Step 4: Emptying Drum emptying through the product piping to the filling line Step 5: Ready for a new load The drum is clean The drum can be filled again

Request for a quote

MÜLLER GMBH

Germany

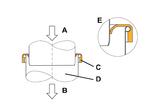

Powder handling without creating dust is always a challenge in industrial processes. Müller dust-free docking systems offer you a simple and reliable solution to this problem. The Müller docking system centers around the silicone rubber cap, whose special lip seal ensures reliable, flexible and dust-free docking. This simple docking method used in conjunction with other Müller components enables a wide variety of dust-free product transfers to be carried out cost-effectively. Standard version Simple docking Accurate positioning not necessary Key to sketch: A - product B - into machine C - silicone elastomer cap D - system inlet tube / cone E - lip seal Version with hopper pressed against lip seal Simple docking if system becomes slightly pressurized Key to sketch: A - product B - into machine C - silicone elastomer cap D - system inlet tube / cone E - lip seal pressed down Telescopic version Simple docking with telescopic intermediate tube Key to sketch: A - product B - into...

Request for a quote

MÜLLER GMBH

Germany

Step 1: Filling Insert plunger Fill product into drum Step 2: Storage Storage Transportation to filling line Step 3: Preperation Use pallet truck to move drum into drum-emptying stand Lower the cover with the handwheel Step 4: Emptying Drum emptying through the product piping to the filling line Step 5: Ready for a new load The drum is 100 % empty It is easy to clean The drum can then be filled again

Request for a quote

MÜLLER GMBH

Germany

Powder handling OEB Level 3+4 At last a stable and robust split butterfly valve system for emptying and filling your highly potent or toxic media. Light to handle and safe to use. You can rely on the Müller Containment Valve to safeguard the health of your employees even as you maintain the purity of your product and protect the environment. The Müller Containment Split Butterfly Valve MCV is in two halves: the active and passive disks. The active disk incorporates the mechanical system for locking both halves together and a manual lever or actuator for opening and closing the valve. The active half of the valve is fitted to the vessel filling or emptying nozzle, and the passive half to the intermediate bulk container. The two halves of the butterfly valve (active and passive disks) must be docked together in order to open the valve. The ruggedly constructed and GMP-compliant locking device ensures accurate location and the safe docking when the two halves are connected. When...

Request for a quote

MÜLLER GMBH

Germany

All our drum lifters do not only handle your drums safely, they also meet GMP-standards. All lifting, inverting and swiveling columns work with electric motors which is very low noise level and operator friendly. For all different types of drums we can offer drum lifters with suitable pick up systems. The slim but stable mast offers the operator a safe visibility to the load. You can manage all handling operations like feeding of tablet presses, capsule filling machines, blister packaging machines, sieves or other transferring tasks with a Müller drum lifter. The lifting operation is always done by electric motor, all other operations like clamping, inverting and swiveling can be done either manually or by electric motors. Drum lifters from Müller are known for economic, save and ergonomic drum handling. Drum lifters with universal clamp lift / swivel / invert column Type FTHSK 300 G2 loads up to 300 kg column height 3.6 m Design: motorized lift manual grip, invert and swivel...

Request for a quote

MÜLLER GMBH

Germany

2.1 / 01 Lidded drum with stackable base Lidded drums with stackable base 2.1 / 02 Lidded drum with flat base and base ring 2.1/02 Lidded drum with flat base and base ring 2.1 / 03 Lidded drum with flat stackable base Lidded drums with flat stackable base 2.1 / 04 Lidded drum with torospherical base Lidded drums with torospherical base 2.1 / 05 Lidded drums with lateral base outlet Lidded drums with lateral base outlet 2.1 / 06 Ultra Clean Drum Ultra Clean Drum

Request for a quote

MÜLLER GMBH

Germany

Müller drum and container blenders - almost like plug and play. Blender or blending column, drum or container – bulk solids such as granules or powders are mixed reliably by an intelligent system; which if required can provide a data report for tracking blender settings such as weight, mixing times and number of revolutions. You therefore have complete documentation for your quality assurance system. Müller drum and container blenders are adaptable for your processes: Gentle action Highly effective Safe Blending parameters can be set With data report Blending column with weighing facility Container tumbler FTHMW 1500 MG8 Lifting weight 1500 kg Height 6 m Design: tumbling and weighing - fully automatic emptying Container Blender Lift / swivel / tumble column Type FTHMS 600 MG7 Loads up to 600 kg Column height 4.0 m Design: motorized lift, swivel, grip and tumble actions Stationary blender for drums Tumbling stand Type FTMh 300 MG1 Loads up to 350 kg Height of unit 1.6...

Request for a quote

MÜLLER GMBH

Germany

2.2 / 01 Lidded drums conical 2.2 / 02 Lidded drums conical with folded base

Request for a quote

MÜLLER GMBH

Germany

Müllers pallet transfer systems and units are available in several types for different applications. Among others we offer automatic feeders for conveying, transfer systems with gate for a process flow in both directions, transfer units with adjustable side walls or fixed side walls. with fixed side walls Standard pallet transfer unit Type PW 800 Loads up to 1000 kg Design: for wooden and aluminum pallets; fixed side walls with motorized adjustable side walls Standard pallet transfer unit Type PW 800 Loads up to 1000 kg Design: for wooden and aluminum pallets motorized side walls with manually adjustable side walls Standard pallet transfer unit Type PW 800 Loads up to 1000 kg Design: for wooden and aluminum pallets manually adjustable side walls with gate for flow in both directions Standard pallet transfer unit Type PW 1000 D2 Loads up to 1000 kg Design: for wooden one-way and aluminum pallets motorized side and end walls automatic sequence Automatic feeder for conveying...

Request for a quoteeuropages also recommends

A selection of companies related to the activity:

A selection of products that might interest you

CTRA

Tunisia

Storage tanks used in the production and processing of corrosive fluids must meet customer safety requirements as well as the standards and regulations in force in the country of delivery. CTRA offers a wide range of solutions for these storage tanks. These can be built entirely in GRP or in GRP - Thermoplastic composites depending on the nature of the stored product. Our tanks cover a range from 0.5m to 6m in diameter and from 0.5 m3 to 300 m3. Other volumes can be designed and built on request.

Request for a quote

CTRA

Tunisia

The transport of corrosive fluids by road, rail and water is highly regulated. Design and quality requirements are very high because these hazardous materials are transported on public roads. CTRA offers a range of solutions for these tank containers, which can be made of GRP / GRP Thermoplastic or GRP Thermoplastic.

Request for a quote

CTRA

Tunisia

We have a skilled quality control team and a laboratory that enables us to carry out trials and tests to ensure the quality of raw materials and finished products. As soon as we receive the raw materials, we carry out the necessary tests to ensure that they comply with the specifications provided by the suppliers. Monitoring and controlling the manufacturing process Ensuring traceability of manufactured products Ensuring that finished products comply with CTRA standards and/or customer specifications by carrying out various in-process checks. Non-destructive testing Visual / Dimensional Polymerisation Destructive testing Calcination test (loss on ignition) > in-house Peel test (separation) > in-house Tensile test > carried out by an approved external body Bending test > carried out by an approved external body

Request for a quote

CTRA

Tunisia

CTRA produces a wide range of boiler-made equipment for chemical processing, including reactors, columns, decanters, mixers, gas coolers, gas scrubbers, odour scrubbers and absorbers, as well as their internal equipment. All this boilerwork is designed by our departments to meet the dynamic and hydrostatic loads required by the various processes. Thanks to the development and mastery of materials, CTRA is able to design a wide range of boilerwork, up to 6 m in diameter, to withstand the most corrosive fluids, whether they operate in a vacuum or at high pressure, from 50°C to 200°C.

Request for a quoteRequest for quotes

Create one request and get multiple quotes form verified suppliers.

- Only relevant suppliers

- Data privacy compliant

- 100% free