NORMIT

Slovakia

Manufacturer/ Producer

Product catalogue preview

NORMIT

Slovakia

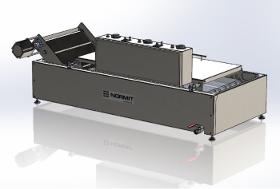

The fryer is designed specifically for professional gastronomic cuisine of hotels, restaurants, and cafes, as well as catering companies and small manufactures. The universal conveyor with its compact dimensions provides a large efficient area of frying. The heating power in the 1-phase version of the fryer is -4 kW, in the 3-phase version 8/12 kW. Technical specifications: Dimensions (LxWxH): 1399x491x400 mm (basic version) Weight: about 60 kg. The working volume of oil: up to 80 liters Working width: 0.35 m Working length in oil: 0.88m Cooking area: 0.4 m² Heating power: 1-phase version: 4kW (cheaper model), 3-phase version: 8/12 kW Maximum heating temperature: 200 ° C (at high temperatures it is better to use special oil for deep frying)

Request for a quote

NORMIT

Slovakia

Drum coater provides easy operation and coating for snack. It’s used for seasoning, salting, adding sugar, adding various ingredients (cinnamon, vanilla, spice ...). Adjustable tilt frame assembly and design exposes each piece of product to the application of liquid and dry coatings. Depending on the application, the dosing of liquids may be through a dosing, perforated pipe and pump or hopper and conveyor system for dry materials. Depending on additional components, the system may be cyclical or continuous. Coating Drum Applications: •Different types of nuts •Chips •Pasta •Cereals •Meat Advantages •AISI 304 stainless steel cylinder. •Motor assembly with variable speed controller. •Variable tilt, stainless steel frame assembly. •Control panel. •Portable casters with brake assembly. •Equipped with paddles for even sprinkling •Drum rotation speed adjustment included •Adjusting the performance of the inclined installation •Possibility to change the height of the supporti

Request for a quote

NORMIT

Slovakia

It is a versatile device for transporting products to a height. It can be used to transport large, small, light or heavy products. The conveyor works very accurately at slow and high speed. Usually it is part of various technological lines and serves for the transport of small products within the line. The conveyor enables fast and efficient transport for a wide range of products. Benefits: •Low water consumption for cleaning •Affordable price •High quality and resistance •Energy savings of 30% •Solid steel construction Advantages: •Fast cleaning and maintenance •Simple installation •Adjustable belt speed •High accuracy conveyor •Low noise •Made of high quality stainless steel AISI 304 •50L hopper volume is at a given angle 38 ° •Conveyor has an adjustable height of 540-840 mm •Conveyor itself can be moved and the angle of the conveyor inclined from 20 ° to 0 °. •Belt PVC.

Request for a quote

NORMIT

Slovakia

Tilting pan with indirect heating and integrated stirrer is designed for frying, steaming, cooking vegetables, fish, meat, sauces, pasta with constant stirring, eliminating the risk of burning or uneven heat treatment. Processes: •Stewing •Cooking •Evaporation •Frying •Deep frying Advantages: • Equipped with a duplicator and electric heating elements. • Fast heating and high thermal efficiency. • Reinforced stirrer with Teflon scraper, which in continuous mode cleans not only the entire bottom, but also the walls of the pan, ensuring a perfect result. • Tilt ensures complete unloading of the working container. • Made of high-quality food-grade stainless steel AISI304 or AISI316L. • Easily sanitizable • No dead zones. Technical specification: Working volume up to 130l Recommended Termooil heating Frying temperature up to 160 C Stirring device: yes Product unloading type: electric driven tilt system Dimensions (LxHxW): 1800x1900x1400 mm Weight: 350 kg

Request for a quoteNORMIT company specializes in the production of technological equipment for the food industry. It develops and produces a wide range of frying equipment, as well as vacuum and pressure equipment with a small amount of oil circulation. The company offers innovative technologies and solutions in the honey processing with a 20-fold acceleration of crystallization, creaming and pasteurization. NORMIT is one of the leaders in oiling, fruit and vegetable processing, mixing, dispersion and various vacuum processing systems. The equipment is manufactured in Europe - at our own production facilities using components of only European manufacturers, which guarantees a long service life and a consistently high quality of the product. Ready-made solutions can optimize the consumption of energy and raw materials, and reduces production time, which ultimately helps to decrease the cost of the final products with saving of a high quality. You’ll find more information on https: //normit.com/? lang=en

Website

Company info

Key figures

-

- Company headcount

- 11 – 50

Organisation

-

- Year established

- 1998

-

- Main activity

- Manufacturer/ Producer

Business info

Trading areas

- International

Delivery areas

Activities of NORMIT

- Machinery and equipment for sock manufacture

- application software for private companies in the service sector

- industrial equipment

Request for quotes

Create one request and get multiple quotes form verified suppliers.

- Only relevant suppliers

- Data privacy compliant

- 100% free