- europages

- >

- Bars - non-ferrous metal

- >

- ZUMBACH ELECTRONIC AG

- >

- Bendcheck Straightness Measuring System

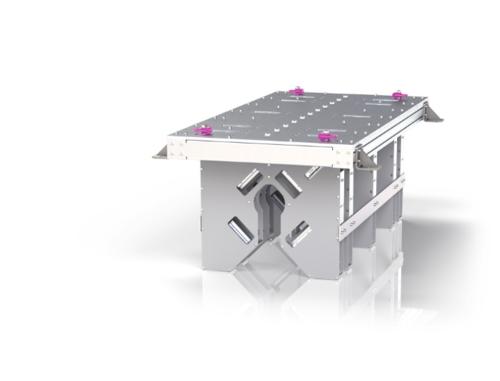

Bendcheck Straightness Measuring System

Non-contact in-line solution for measuring the straightens of rods & tubes

Description

The BENDCHECK system is suitable for in-line production optimization in the steel and metal industry. The measuring solution enables in-line quality assurance in the production of tubes and rods and eliminates the need for complex manual straightness measurements. Properties: Synchronous real-time scan to monitor bending of the product 3 to 5 non-contact measuring stations with 1 to 3 measuring axes Direct integration into the existing production process Constant quality assurance, also after the straightening process Recording of statistics, ensuring traceability Time savings thanks to automatic measurement control Continuous measurement without slowing down the production process Replaces manual measurements by means of off-line stations Optional measurement of head and tail bending with additional measuring stations. Benefits: Cutting-edge optics & laser scan technology Maximum accuracy & stability Extremely high sampling rate Comprehensive quality control

Documents

Similar products

ALUMINIUMWERK UNNA AG

Germany

On request, we can supply aluminium alloys in the form of rod or bar. These are available in most of the commercially available aluminium alloys. The tolerances of extruded aluminium rods and bars can also be further improved by subsequent drawing. In recent years, ALUnna has specialised in the production of rod and bar meeting the highest quality standards. If you require a specific delivery option for rod or bar such as special testing then we will definitely find a solution for you.

Request for a quote

EC PLAZA

South Korea

Ferro-Mon Sensor measures the concentration of iron by detecting the change in magnetic flux when magnetic particles such as Fe, Ni,.. etc are collected in the sensor probe. This sensor outputs the amount of magnetic material as “Fe saturation %” so that it detects and evaluates abnormal wear conditions of rotating machines. Two output channels for fine particles and large particles can detect normal wear and abnormal wear. ▪ Real-time monitoring of iron concentration % ▪ Easy installation ▪ Sensor probe and control panel are integrated in one sensor ▪ Integrated Ferro-Mon Sensor can be applied for all equipment. ▪ Particularly, user can get the best effect when applying to gearboxes, engines, transmissions, pumps, bearings, etc., which are vulnerable to wear.

Request for a quote

PLANSEE SE

Austria

Rods made of tungsten and its alloys are available in the diameter range 2mm to 80mm in different lengths in the Plansee Online Shop. Order fast and easily in the producer's onlineshop: www.plansee.com/shop. Special dimensions are available on request.

Request for a quote

LIA MOOS

Netherlands

We are the best source for ferrous scrap metal and non-ferrous scrap metals. With five recycling locations scattered around EU, and an active demolition and dismantling service we have a huge supply of scrap metal. In addition, we buy scrap metal from national and international customers and resell it to people just like you at affordable prices. As one of the largest scrap metal dealers in the EU, our business, for the past 40 years, has always focused on quality. So while we have a huge supply of scrap metal it is all graded and sorted according to the standards of the metal industry. What that means for you is that when you buy scrap metal you are not just buying a ton of copper, but a ton of copper that is sorted, process and rated according to the standards set forth by the metal industry. We accept a wide variety of ferrous and non-ferrous scrap and surplus metal products.

Request for a quoteRequest for quotes

Create one request and get multiple quotes form verified suppliers.

- Only relevant suppliers

- Data privacy compliant

- 100% free