OFFICINE CONTERNO SRL

Italy

Manufacturer/ Producer

OFFICINE CONTERNO SRL

Italy

Officine Conterno designs and manufactures crushing, screening and aggregate washing plants for the production of concrete, bituminous conglomerates, road foundations or railway ballast. Jaw crushers, primary, secondary and tertiary mills, feeders, rotating screens, vibrating screens, vane or barrel scrubbers, and cyclonic separation groups ... These are just some of the machines in our product range.

Request for a quote

OFFICINE CONTERNO SRL

Italy

The major and growing concern for the environment and the reduction of raw material consumption has led to the design of waste recycling plants with a high technological value and low environmental impact. Officine Conterno is able to manufacture complete plants for the recycling and exploitation of aggregates of various kinds such as: BUILDING DEMOLITION RUBBLE BRICK PROCESSING SCRAPS STEEL AND FOUNDRY SLAG UNBURNED ASHES FROM MSW INCINERATORS FLAT AND HOLLOW GLASS SCRAP After undergoing a crushing process, iron removal, screening and separation of non-ferrous metals, all these materials are placed back on the market and are used in building and industry.

Request for a quote

OFFICINE CONTERNO SRL

Italy

We produce transportation and storage plants for any type of bulk material: from aggregates, to plant biomass waste, cereals, up to milling and food. Conveyor belts with rubber mats, metal plate conveyors, redlers, bucket elevators, screw conveyors, silos and hoppers of various shapes and capacities. With the experience gained over the years, we can design and construct conveyors for the most demanding applications such as waste from differentiated MSW collection, RDF and ash from incinerators, as well as for m ore traditional uses such as the transportation of sands or gravels.

Request for a quote

OFFICINE CONTERNO SRL

Italy

Officine Conterno designs and constructs machines and mobile plants attached to wheels, tracks, roll-offs or sleds. These plants do not come in a standard model but are studied and designed to suit individual customer requirements. Precisely for this reason we are able to provide the most diverse range of mobile machines, from single conveyor belts on tracks to roll-off crushers up to complete crushing and screening plants.

Request for a quote

OFFICINE CONTERNO SRL

Italy

Belt feeders are recommended for the extraction and dosage of aggregates from hoppers, ensuring a constant and regular flow rate with small and medium size aggregate, in cluding in the presence of high percentages of fine matter. They are usually mounted with variable speed motors and/or inverters for fine adjustment of the speed of extraction and the flow rate.

Request for a quote

OFFICINE CONTERNO SRL

Italy

Studied for the feeding of aggregates, including poorly sliding clayey or silty materials. Carriage feeders are very reliable machines suitable for continuous operation even in harsh operating conditions. The flow rate control is possible by adjusting the stroke of the carriage by means of a flanged cam. They are made in different sizes depending on the particle sizes and flow rates to be obtained.

Request for a quote

OFFICINE CONTERNO SRL

Italy

Machines studied for primary feeding of crushers for rock or alluvium. They guarantee a constant feed and very high flow rates. Made in heavy construction, they consist of a track with articulated plates obtained from casting or extruded. Motorisation is applied with a multi-stage gearmotor. Available in widths from 650 to 1200 and modular in length up to 10/12 metres.

Request for a quote

OFFICINE CONTERNO SRL

Italy

Designed for the supply of medium size aggregates, ALV screening feeders make it possible to separate the fine from the coarse fraction. These machines are generally used for the feeding of primary or secondary crushers. The vibration is generated by adjustable eccentric mass electric moto-vibrators . Made in different sizes depending on the particle sizes and flow rates to be obtained.

Request for a quote

OFFICINE CONTERNO SRL

Italy

Studied for the extraction and dosage of bulk materials of various sizes. The adjustable intensity, unidirectional vibration is generated by eccentric mass electric moto-vibrators. Made of suitably bent and stiffened sheet metal, they are used in various sectors, from the steel to the mining industry.

Request for a quote

OFFICINE CONTERNO SRL

Italy

Officine Conterno has been operating in the crushing machine sector since 1979 and over the years has gained experience and knowledge of the major Italian and foreign brands of crushing machines. We provide full maintenance, replacement or complete revamping services for crushers, mills and roller mills. We have a large pool of used and refurbished machines and we can provide any type of spare parts for wear or mechanical faults.

Request for a quoteManufacturer/ Producer

Localita' Valle, 4/B

12060 Piozzo - Italy

europages also recommends

A selection of companies related to the activity:

A selection of products that might interest you

UGUR MAKINA CRUSHING & SCREENING

Turkey

Durable against wearing. It has a strong and durable body structure and allows long working time with minimum maintenance. It consumes less energy and operates at high capacity at low kw. Easily adjustable hydraulic structure enables reducing labor time

Request for a quote

UGUR MAKINA CRUSHING & SCREENING

Turkey

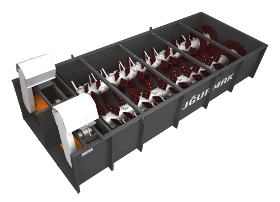

They are produced with double shafts. On the shaft, there are detachable fixed spiral leaves and washing shovels lined up with the most suitable combination. It is very easy to replace shovels and spiral leaves since they are detachable connected. These shafts are driven by motor, reducer and belt pulley system.

Request for a quote

UGUR MAKINA CRUSHING & SCREENING

Turkey

The most preferred reason for UĞURMAK brand mobile crushing units is the ease of assembly and disassembly. Temporary project works such as dams, road construction may need to be moved to a different site at the end of the project. In such cases, as these plants offer ease of transportation, they significantly reduce transportation costs.

Request for a quote

UGUR MAKINA CRUSHING & SCREENING

Turkey

UĞURMAK CDK Series Primary Impact Crushers have a design that allows the rotor, two pendulum systems and wear plates to work in harmony. Thanks to this compatibility, it offers high performance and low operating costs. It can provide very high size reduction ratios in breaking not very hard and non-abrasive materials. Thanks to these advantages, they are preferred in primary crushing stage in crushing and screening plants. According to the design of the facility, they can be manufactured as mobile, with fixed steel legs, with fixed concrete legs, with fixed skid chassis.

Request for a quoteRequest for quotes

Create one request and get multiple quotes form verified suppliers.

- Only relevant suppliers

- Data privacy compliant

- 100% free