O.M.C. COLLAREDA S.R.L.

Italy

Manufacturer/ Producer

O.M.C. COLLAREDA S.R.L.

Italy

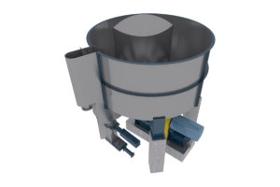

HC Pulper has been designed to optimize the slushing effect which is a milestone along the deinking process.

Request for a quote

O.M.C. COLLAREDA S.R.L.

Italy

It’s the first barrier against contaminants. Thanks to its action, contaminants like plastics, metallic pieces, etc. are taken out.

Request for a quote

O.M.C. COLLAREDA S.R.L.

Italy

HDC Cleaner, by centrifugal separation, allows the evacuation of contaminants as staple, stones, etc.

Request for a quote

O.M.C. COLLAREDA S.R.L.

Italy

Centrifugal action, fundamental to optimize the separation, is ensured by the geometry of the cleaner itself.

Request for a quote

O.M.C. COLLAREDA S.R.L.

Italy

Depending on the process chosen and customer requests, LC screens could be preferred to MC ones, or could be even combined together.

Request for a quote

O.M.C. COLLAREDA S.R.L.

Italy

The function of WU is to remove from the stock ashes, ink particles still present and fines.

Request for a quote

O.M.C. COLLAREDA S.R.L.

Italy

Pressurized DUP aim is to disperse the contaminants still present into the stock to a dimension no more visible to the human eyes.

Request for a quote

O.M.C. COLLAREDA S.R.L.

Italy

LCC Pulper has been designed to optimize the slushing effect by increasing either cutting and opening of the fibers.

Request for a quote

O.M.C. COLLAREDA S.R.L.

Italy

Part of the stock is conveyed to DSC and its function is doing a stock pre screening and keeping, as much as possible, pulper’s vat clean.

Request for a quote

O.M.C. COLLAREDA S.R.L.

Italy

The function of this equipment is to recover water and fiber from the dumping screen light reject and to convey it back to the pulper.

Request for a quoteManufacturer/ Producer

VIA LAZIO 10

36015 Schio - Italy