OTTO BIHLER MASCHINENFABRIK GMBH & CO. KG

Germany

Manufacturer/ Producer

OTTO BIHLER MASCHINENFABRIK GMBH & CO. KG

Germany

Specifications: Stroke rate: steplessly adjustable from 5 to max. 350 1/min. Press: nominal force 200 kN, stroke 12 mm Slide units: max. nominal force 60 kN, max. stroke 50 mm Feed pitch: servo feed: any; mech. feed: max. 240 mm with feed cycle reduction Material: max. strip width 60 mm, max. wire 4 mm (larger strip widths on request) Dimensions: witdth 3,090 mm x depth 2,026 mm x height 2,320 mm (with enclosure) Weight: approx. 3,900 kg (without tooling)

Request for a quote

OTTO BIHLER MASCHINENFABRIK GMBH & CO. KG

Germany

Specifications: Stroke rate: steplessly adjustable from 5 to max. 350 1/min. Press: nominal force 150 kN, stroke 12 mm Slide units: max. nominal force 60 kN, max. stroke 50 mm Feed pitch: servo feed: any; mech. feed: max. 240 mm with feed cycle reduction Material: max. strip width 60 mm, max. wire Ø 4 mm (larger strip widths on request) Dimensions: witdth 2,590 mm x depth 2,100 mm x height 2,450 mm (with enclosure) Weight: approx. 3,160 kg (without tooling)

Request for a quote

OTTO BIHLER MASCHINENFABRIK GMBH & CO. KG

Germany

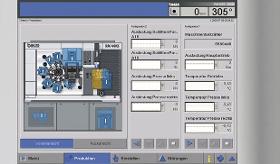

VariControl VC 1 - One control platform for all tasks With the VariControl VC 1 machine and process control system, Bihler emphasizes the keywords „Ease of Use“ and „Process Safety“ at a new, higher level. With state of the art software and hardware features, the intelligent control system guarantees greater efficiency in your production. The highly flexible control platform allows you to easily control even the most complex automation solutions in the field of stamping and forming assembly technology – on all Bihler machine types. The integrated „bASSIST“ diagnostic and online help system assists your machine operator just like a second operator at his or her side. Videos, graphics and individually created data simplify adjustment, setup and maintenance operations significantly. The continuous monitoring of all machine and tool functions guarantees maximum machine availability.

Request for a quote

OTTO BIHLER MASCHINENFABRIK GMBH & CO. KG

Germany

Process optimization already starts with the corresponding software. Bihler Software bNX provides technically ground-breaking functions to support the complex tasks required for development, analysis, manufacturing, marketing and maintenance. The development and design processes of punching and bending tools can be analyzed, configured, conceived and simulated with the help of bNX technology software. Virtual product development, which makes verification possible ahead of production, reduces the risks associated with development and development times.

Request for a quote

OTTO BIHLER MASCHINENFABRIK GMBH & CO. KG

Germany

Specifications: Stroke rate: continuously variable from 5 to max. 250 cycles/min. Press: nominal punching capacity 300 kN, stroke 16 mm Slide units: max. nominal forming capacity 90 kN, max. stroke 95 mm Feed pitch: mech. feed: max. 500 mm, with feed cycle reduction, servo feed: any feed pitch Material: max. strip width 80 mm, max. wire-Ø 6 mm Dimensions: width 3.140 mm, depth 1.583 mm, height 2.220 mm Weight: approx. 3.000 kg (without tooling)

Request for a quote

OTTO BIHLER MASCHINENFABRIK GMBH & CO. KG

Germany

Specifications Stroke rate: continuously variable from 5 to max. 250 1/min. Press: nominal punching capacity 300 kN, stroke 16 mm Slide units: max. nominal forming capacity 90 kN, max. stroke 95 mm Feed pitch: mech. feed: max. 200 mm or 500 mm, with feed cycle reduction, servo feed: any feed pitch Material: max. strip width 80 mm, max. wire diameter 6 mm Dimensions: width 3.140 mm, depth 2.250 mm, height 2.390 mm Weight: approx. 6.000 kg (without tooling)

Request for a quote

OTTO BIHLER MASCHINENFABRIK GMBH & CO. KG

Germany

Highlights: Very fast “Time to Market” for new stamped and formed parts made of wire and strip as well as progressive components •Quick feasibility statements and precise quotations (“Bihlerplanning” WebApp, defined process limits) •Simple and structured design methodology of bNX software (WebApp for design support, templates) •Very short tool production times (high proportion of standard machine and tool parts) •Up to 70% lower manufacturing costs compared to conventional forming tools •Extremely fast, 100% reproducible setup operations (automatic slide positioning, quick clamping systems, data retrieval from VC 1 control system) •Lower logistics and maintenance costs

Request for a quote

OTTO BIHLER MASCHINENFABRIK GMBH & CO. KG

Germany

Highlights: The new B 20K high-performance welding control system combines all process, measurement and monitoring systems into one comprehensive system. Stepless welding frequency adjustment between 1,000 and 20,000 Hz guarantees a highly dynamic and even finer control compared to low-frequency technologies for even better resistance welding results. From micro to macro welding processes, from resistance soldering processes to heating processes such as annealing, the B 20K covers an immense range of applications. Furthermore, up to 18 servo axes for e.g. controlling contact welding equipment can also be used to integrate press applications and other options in the B 20K.

Request for a quote

OTTO BIHLER MASCHINENFABRIK GMBH & CO. KG

Germany

Specifications: Part size: max. 50 x 50 x 50 mm Part weight: max. 80g / part Bunker volume: 10 – 50 litres (depending on parts) Feeding speed: max. 30 m/min. (depending on part geometries)

Request for a quote

OTTO BIHLER MASCHINENFABRIK GMBH & CO. KG

Germany

Specifications: Speed range: 500 - 4500 1/min. Max. torque (Nm): 27 Thread diameter: M3 - M14

Request for a quoteManufacturer/ Producer

Lechbrucker Straße 15

87642 Halblech - Germany

europages also recommends

A selection of companies related to the activity:

A selection of products that might interest you

PERGEL METAL

Turkey

POWER SOLUTION, UPS, SHEET METAL, POWER, GENERATOR, BOARD, LAZER CUT, PANEL, METAL CUTTING, LAZER CUTTING, CNC CUTTING

Request for a quote

PERGEL METAL

Turkey

Bespoke, Tailormade Electrical Distribution Board With 3 mm Galvanized Steel, Swing Frame, Dual Powder Coated.

Request for a quote

PERGEL METAL

Turkey

POWER SOLUTION, UPS, SHEET METAL, POWER, GENERATOR, BOARD, LAZER CUT, PANEL, METAL CUTTING, LAZER CUTTING, CNC CUTTING

Request for a quote

PERGEL METAL

Turkey

POWER SOLUTION, UPS, SHEET METAL, POWER, GENERATOR, BOARD, LAZER CUT, PANEL, METAL CUTTING, LAZER CUTTING, CNC CUTTING

Request for a quoteRequest for quotes

Create one request and get multiple quotes form verified suppliers.

- Only relevant suppliers

- Data privacy compliant

- 100% free