- europages

- >

- Packaging

- >

- GIZELIS ROBOTICS

- >

- PACKAGING APPLICATIONS

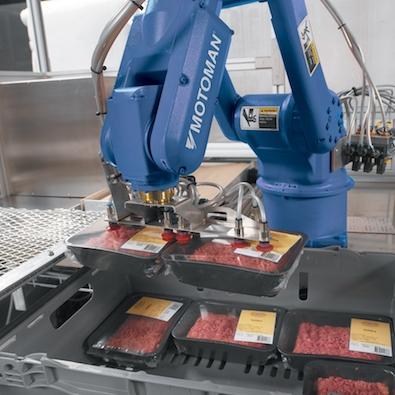

PACKAGING APPLICATIONS

Description

An IP 67 rating stands for full protection against dust ingress and protected operation against immersion and water penetration (designated by the second digit). Moreover, robotic systems feature smooth finishing, so there are no areas for bacteria build-up, and integrated through-the-arm cabling for problem-free transfer of signals and air, as well as easy, risk-free cleaning with any type of cleaners. Moreover, a food industry-specific grease is used in their spindle reducers. Robotic systems’ main advantage lies in the fact that they may work together with any packaging machinery (carton sealer, film etc) to offer increased operating flexibility to any application. Typically, packaging robots are followed by palletizing robots, however if line speeds are low, packaging robots may also undertake palletizing for additional production cost savings. For all the above reasons, it is easy to understand why all food and pharmaceutical companies apply robots in their production lines.

Similar products

PAPETERIE DE MANDEURE

France

Ecological and innovative, FoodPack is a range of papers and cards suitable for direct food contact, with or without grease barrier. FoodPack is dedicated to cold and hot applications meeting the requirements of food packaging. FoodPack® : for food contact FoodPack® CT : colorless paper with grease barrier – cold food packaging FoodPack® TGS : colored paper with grease barrier – cold food packaging FoodPack® HT : with grease barrier - food packaging – hot applications Comply with following regulations : EU 1935/2004, BfR36, BfR36/2, DM 21.3.73, FDA, EN1230-2, DIN 10955

Request for a quote

BRUNO UNGER GMBH & CO KG

Germany

For cutting, perforating or punching of foil and paper products

Request for a quote

SPIES PACKAGING / SPIES KUNSTSTOFFE GMBH

Germany

Following the market trend, the new SPIES PC meets all requirements - from weight optimization and resource conservation to the use of renewable raw materials. Your desired article geometry can be developed individually.

Request for a quoteRequest for quotes

Create one request and get multiple quotes form verified suppliers.

- Only relevant suppliers

- Data privacy compliant

- 100% free