- europages

- >

- Cleaning machines- industrial

- >

- PERKUTE MASCHINENBAU GMBH

PERKUTE MASCHINENBAU GMBH - Hersteller für industrielle Teilereinigungsmaschinen auf wässriger Basis im Spritzverfahren

Germany

Manufacturer/ Producer

PERKUTE MASCHINENBAU GMBH

Germany

Industrial parts cleaning with the Perkute Toploader Series The PERKUTE rotating basket cleaning machine from the Toploader series is used wherever effective and inexpensive cleaning of parts of any kind is necessary. The rotating basket, designed for large weights, is powered by means of a low-wear friction wheel drive and the aqueous cleaning in the spray process takes place by means of a nozzle pipe system with special flat-spray nozzles that is arranged on 3 sides. A powerful washing pump supplies the system with the necessary pressure and volume flow. The parts cleaning machines, made completely of non-rusting special steel, istinguish themselves by their compact and robust construction as well as simple handling. They are mobile to deploy and designed to be space-saving. Customisation for individual cleaning tasks can be optimised through a comprehensive range of accessories.

Request for a quote

PERKUTE MASCHINENBAU GMBH

Germany

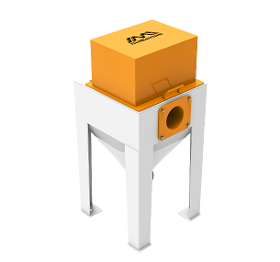

A solid single-chamber parts cleaner for automatic water based spray cleaning. This series is extendable by varies extras which can be retrofitted. The RC-machine is a low costs entry to the modern world of industrial parts cleaning. The PERKUTE-system: economically - environmental – effektive Basic equipment Compact and sturdy construction Made of stainless steel Simple operation Space-saving 3D-blast pipe system incl. fan nozzles Low water pressure switch as dry-run protection Suction filter made of stainless steel front of the pump Adapter for steam extraction Basket drive by water pressure (RC 68, RC 82) Electronic basket drive (RC 122, RC 162) Preparation for electronic basket drive (RC 82) 2“ socket slide vlave for the tank emptying Safety limit switch at cover

Request for a quote

PERKUTE MASCHINENBAU GMBH

Germany

A compact and sturdy construction characterizes the SP machine which is an closed fully automatic machine. The SP meets the highest requirements where total cleanliness and dryness are concerned. We adjust our production to individual demands and are therefore able to offer tailor-made solutions. The PERKUTE-system: economically - environmental – effektive Basic equipment Made of stainless steel Compact and sturdy construction Simple operation Mobile, can be used anywhere 3D-blast pipe system incl. fan nozzles Low water pressure switch as dry-run protection Electronic basket drive Tank cover in the return flow, filter baskets incl. Long wash liquid service life due to the skimmer Programmable operation operating counter incl. Automatic steam extraction by air blower Powerful washing pump High permissible basket load Safety limit switch at cover 2" socket slide valve for the tank emptying

Request for a quote

PERKUTE MASCHINENBAU GMBH

Germany

This ergonomic advanced development of the proven SP series distinguishes itself through a user-friendly charging system in the form of a movable loading trolley. For large batches, it can also alternatively be equipped with a loading ramp or lateral movement station.In this manner, loading and unloading processes, even of heavy or voluminous components, can be carried out in an optimized manner. The PERKUTE-System: economically - environmental – effektive Basic equipment Made of stainless steel Compact and sturdy construction Simple operation Mobile, can be used anywhere 3D-blast pipe system incl. fan nozzles Low water pressure switch as dry-run protection Electronic basket drive Tank cover in the return flow, Long wash liquid service life due to the skimmer Programmable operation operating counter incl. Automatic steam extraction by air blower Powerful washing pump High permissible basket load Safety limit switch at cover 2" socket slide valve for the tank emptying Load...

Request for a quoteIn 1967, PERKUTE began developing and producing systems for cleaning metal and degreasing in the town of Rheine in western Germany. In 1996, PERKUTE was incorporated into the STENHØJ GROUP, which has worldwide operations. Since 2001, PERKUTE workers have been developing and producing automatic systems at the site in Rheine (Düsterbergstraße) for cleaning parts according to customer-specific requirements. PERKUTE has been certified in accordance with DIN EN ISO 9001 since 2007. The systems for cleaning parts are used across the entire production and manufacturing industry, mechanical and plant engineering and also in the repairs and maintenance sector. PERKUTE is now one of the leading manufacturers in this field.

Website

Documents

Manufacturer/ Producer

Düsterbergstraße 10

48432 Rheine - Germany

Company info

Key figures

-

- Company headcount

- 11 – 50

Organisation

-

- Year established

- 1967

-

- pages.epage-home.site-status

- Registered office – Parent company

-

- Main activity

- Manufacturer/ Producer

Business info

Trading areas

- Regional

- National

- European

- International

Delivery areas

Activities of PERKUTE MASCHINENBAU GMBH

- Cleaning machines, industrial

- detergents

europages also recommends

A selection of companies related to the activity:

A selection of products that might interest you

WESPY INDUSTRIAL PARTS WASHING MACHINES

Turkey

The part washing machine is designed to easily clean dirty parts with a small size and complex structure in the shortest time possible. Thanks to its brush, the person performing the washing process can carry out any kind of cleaning in the dirty part in detail. It is an ideal parts washing machine for using in small areas.

Request for a quote

EC PLAZA

South Korea

As the world’s global leader in semiconductor equipment manufacturing, VISION SEMICON has cease-lessly worked with the management philosophy of merging future-oriented technology with today’s technology in hopes of providing happiness and contentment for all humans. As the result, VISION SEMICON has received reviews from clients worldwide for its plasma treatment process equipment, which is the most important procedure in semiconductor production process, oven system and unmanned semiconductor production process.

Request for a quote

CRYOSNOW GMBH

Germany

• For large surfaces and stubborn contaminations • Powerful round nozzles • Flat nozzles with blasting widths of up to 100 mm (4") • Available as Desktop and Trolley • No power supply, as driven pneumatically

Request for a quote

MAKENAS GRAIN MILLING TECHNOLOGY

Turkey

It is used to clean jet filter bags that lose their filtering function over time due to dust particles

Request for a quoteRequest for quotes

Create one request and get multiple quotes form verified suppliers.

- Only relevant suppliers

- Data privacy compliant

- 100% free