POREX TECHNOLOGIES GMBH - Making the world safer, healthier and more productive.

Germany

Manufacturer/ Producer

POREX TECHNOLOGIES GMBH

Germany

Improve lighting performance with reflective media For instrumentation and testing systems, our POREX Virtek™ sintered PTFE sheets and molded 3-D parts offer multi-directional light, ideal for machine vision systems and integrating spheres where uniformly lighting surfaces of different geometries is a must. Constructed with outstanding reflectance, POREX Virtek™ PTFE: Minimizes glare, with its 100% Lambertian reflection of light. Supports itself when handled - Does not require a backing or support scrim for handling. Supports versatile assembly options – Heat staking or vibrational welding can be used to secure the POREX Virtek™ PTFE to the lighting or housing structure.

Request for a quote

POREX TECHNOLOGIES GMBH

Germany

Separate water easily from your oil and gas streams From bonded fiber to sintered porous media, Porex creates media to separate or filter water from oil and gas streams. Specifically designed for your oil and gas application, our water separation media: Reduce material usage - Porex bonded fiber material products can replace the need for multiple medi layers commonly found in oil/water separation filters. Self support - Filters can be self-supporting and customized into various shapes and sizes. request sample ask an engineer

Request for a quote

POREX TECHNOLOGIES GMBH

Germany

Optimize insecticide release performance Repel pests in the home with both porous fiber and sintered particle wicks designed for plug-in insecticides. POREX ® wicks deliver insecticide from the bottle or container to the heater using capillary action, and then diffusing the insecticide into the air at a high temperature. To optimize performance or to meet specific design criteria, our wicks are available with different capillary levels, and multiple wicks can be used in one device to optimize performance or meet specific design criteria. Porous fiber wicks work well at high temperature, achieving a high release of insecticide per day, while our sintered particle wicks deliver a consistent insecticide release over the life of the product. Both types of wicks are available in many shape options, including 2D shape capability for the porous fiber technology and 3D shape capability for the sintered particle technology. Features High temperature effectiveness Engineered capillary...

Request for a quote

POREX TECHNOLOGIES GMBH

Germany

Better p rotect crops, lawns and gardens from pests POREX® scent attraction wicks absorb and hold biological scents to attract specific insects. Used to attract insects into traps for consumer and agricultural pest control where pesticides are not an option, our wicks: Absorb the biological scent Hold the biological scent for a specified period of time Meet your specific design criteria – Many shape options are available, including two-dimensional shapes for porous fiber technology and three-dimensional shapes for sintered particle technology. Features Absorb and hold a biological scent Engineered porous structure to maximize surface area and scent loading Materials Offered Advanced porous materials (PE, PP) Porous polymeric fiber Formats Available 2D fiber shapes 3D molded shapes request sample ask an engineer

Request for a quote

POREX TECHNOLOGIES GMBH

Germany

Increase performance of your pneumatic systems Powering pneumatic machines requires clean and conditioned air or gas. Our pneumatic filters are designed to work together with regulators and lubricators (FRL units), to offer outstanding performance and a lower-cost alternative to traditional sintered-metal filters. Specifically designed to provide an excellent combination of particulate filtration, air flow and back pressure performance, while complying with strength and aesthetic requirements, these single-component molded filters: Meet your filtration requirements – Optimized design meets filtration, airflow and pressure drop requirements. Reduce costs – Sintered polymer filters are more cost-effective than sintered metal. Improve machine longevity – Design is optimized for reliability, efficiency and longevity of pneumatic machinery. Features Work together with regulators and lubricators (FRL units) to deliver clean and conditioned compressed air or gas Strong and rigid for...

Request for a quote

POREX TECHNOLOGIES GMBH

Germany

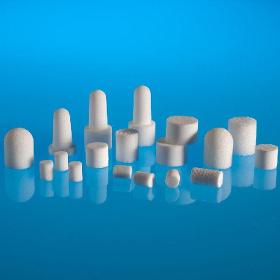

Effectively reduce pneumatic equipment noise Engineered to provide an optimal balance between noise reduction and acceptable backpressure in the pneumatic system, our porous plastic silencers offer numerous advantages over metal acoustical silencers. Our porous plastic silencers are designed with a significantly lower weight along with greatly improved corrosion resistance and the ability to filter particles and aerosols. This leads to greater durability, assembly speed and cost-efficiency for our partners. Designed with a solid integrated threaded adapter to ensure easy mounting on pneumatic equipment, our silencers: Fit most standard valves – Offered in an extensive selection of sizes designed to fit most standard valves, including NPT, BSP, M5 and “push-in” styles. Enhance equipment longevity – Effectively filters particulates and aerosols. Reduce pneumatic equipment noise – Engineered with a porous plastic structure, offering greater noise reduction compared to metal and...

Request for a quote

POREX TECHNOLOGIES GMBH

Germany

Strengthen and enhance membrane performance Customized and developed for specific end-use applications, POREX ® membrane support media are used as substrates for fragile membranes to provide structural strength and enhanced performance. Available in polyethylene (PE) and various customized geometries, our membrane support media: Support fragile membrane s with a strong and durable media. Enhance performance of specific end-use applications with custom designs Materials Offered Advanced porous materials (PE) Formats Available 3D molded shapes One piece solid and welded options including tubes and sheets Customization options for specific applications Request Sample ask an engineer

Request for a quote

POREX TECHNOLOGIES GMBH

Germany

Greater comfort, sealing and support for face mask applications Expect greater comfort and support for consumer and industrial face mask applications with POREX® latex-free foam. Tailored for your application, our latex-free foam: Conforms to nasal and facial contours – Shapes to end-user nasal and facial contour for superior seal and fit, which enhances safety during use. Controls perspiration for added comfort Meets custom end-use requirements – Customized durometer, color and width to meet your face mask specifications. Features Conforms to nasal-facial contour for maximum comfort and fit Latex-free and hypoallergenic Materials Offered High purity polyurethane foam Formats Available Customized size, durometer, color and width Request Sample ask an engineer

Request for a quote

POREX TECHNOLOGIES GMBH

Germany

Reduce time and costs with a comprehensive sample collection, transport, and storage system Our unique patented dried-matrix technology allows the porous matrix to collect, transport, store and release a sample upon demand – all in one simple system. With the ability to be customized for low-to-high throughput formats, our technology: Reduces potential costs–Can eliminate costs associated with biohazard shipping and transportation, while maintaining efficiency in the lab. Protect sample integrity–Preserves, stabilizes and maintains the sample with a patented proprietary Porex technology. Decreases workflow time–Shortens analysis time by eliminating the reliance on additional kit components.

Request for a quote

POREX TECHNOLOGIES GMBH

Germany

Extract more formula with cushion compact reservoirs The POREX® fiber cushion is a patent-pending design consisting of chemically stable components that can be used with a variety of formulas, including solvents, oils, water-based solutions and more. Our cushion compact reservoirs: Extract more formula from the compact than other solutions on the market Use a unique gradient density to drive formula from the bottom of the reservoir to the top for easier application Ensure consistent release of formula across the life of the compact

Request for a quoteManufacturer/ Producer

Industriestrasse 21

02692 Obergurig, Ot Singwitz - Germany