- europages

- >

- Measurement - Equipment & Instruments

- >

- FLUKE PROCESS INSTRUMENTS GMBH

- >

- Raytek GS150/GS150LE Thermal Imaging Systems/Glass Industry

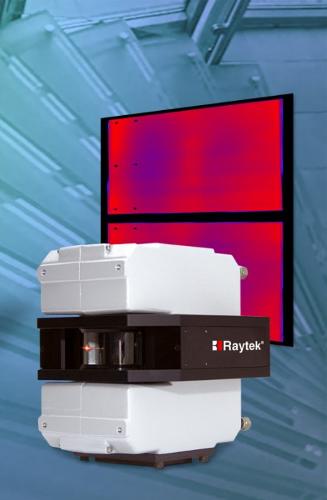

Raytek GS150/GS150LE Thermal Imaging Systems/Glass Industry

Infrared line scanner thermal imaging system – glass bending, forming, tempering

Description

Raytek GS150 thermal imaging systems enable automated quality control in glass bending, forming, annealing, and tempering processes. The GS150LE variant is especially designed for Low-E (low emissivity) glass / one-side coated flat glass. It features automatic emissivity correction. The systems are based on the Raytek MP150 infrared line scanner, which has a max. resolution of 1024 points per line, a max. 150 Hz scanning frequency, and an up to 90° wide field of view. SYSTEM PROPERTIES • Automated temperature monitoring • Visualization on PC • Ethernet TCP/IP interface integrated in the line scanning system • PC-independent alarm output • PC-independent analog outputs 3 x 4 – 20mA BENEFITS • Improve profitability and product quality • Reduce set-up time • Detect defects quickly • Automate quality monitoring for ISO9000 • Reduce scrap • Efficiently manage the heat balance in the oven • Automatically adjust the emissivity value when changing glass types or coatings

- Measurement - Equipment & Instruments

- glass industry

- thermal imaging

- temperature

Product characteristics

- Measured temperature range

- 100 to 950°C (212 to 1742°F)

- System accuracy

- ±0.5°C or ±3°C (6°F)

- Repeatability

- ±1°C (2°F)

- Optical resolution

- 170:1 (90% energy)

- Ambient temperature

- 0 to 50°C (32 to 122°F), with water cooling up to 180°C (356°F)

- Field of view

- 90°

- Points per line

- Up to 1024 pixels

- Scan rate

- Up to 150 Hz

- Power supply

- 24 VDC ± 25%, 1 A

- Ethernet communication

- TCP/IP (10/100 Mbit/s)

- Serial communication

- RS485

- Analog outputs

- 3 x 4 – 20 mA

- Alarm output

- Relay, contacts: 30 V, 1 A

Documents

Videos

Similar products from FLUKE PROCESS INSTRUMENTS GMBH

FLUKE PROCESS INSTRUMENTS GMBH

Germany

ThermoView TV40 is a high-performance industrial thermal imaging system for fixed installation designed for factory automation applications. It integrates a visible-light camera and software for temperature control, monitoring, and data archiving. • Wide temperature range: -10 to 1200 °C (14 to 2192 °F) • Rugged aluminum housing, IP67 (NEMA 4) • Ambient temperatures to 200 °C (392 °F) with high-temperature enclosure • Air purge and accessories available • IR-Fusion technology: simultaneous thermal and visible sighting • Remote motorized focus • 320 x 240 and 640 x 480 focal plane array • 9 or 60 Hz models available • GigE Vision interface • LAN/Ethernet with PoE for communication with the camera provides access to Ethernet, Web server and ThermoView Software • Multiple field interchangeable lens options • 2-year warranty

Request for a quote

FLUKE PROCESS INSTRUMENTS GMBH

Germany

The Raytek MP150 infrared linescanner is designed for temperature monitoring in demanding industrial environments. It generates accurate thermal images of moving objects, scanning up to 90° wide fields of view with a motorized mirror at up to 1024 points per line and at a max. 150 Hz frequency. An internal high-speed microprocessor calculates the temperature of the individual measurement points. — Real-time thermal line-scanner system for continuous or discrete process measurements — Optical resolution up to 200:1 — Built-in line laser for rapid alignment — On-board Ethernet TCP/IP communication — Wide choice of models and spectral responses The Raytek MP150 includes provision for air or water-cooling, three configurable analog outputs, and two-way digital communications. It can be used in standalone mode, connected to a single PC or integrated into a process control system using the Windows-based DataTemp DP software for remote configuration and real-time process monitoring.

Request for a quote

FLUKE PROCESS INSTRUMENTS GMBH

Germany

Kiln shell temperatures are monitored along the entire length of the kiln. The infrared line-scanning system detects kiln hot spots due to refractory loss, damage, or wear. Data from up to 4 scanners or individual point sensors (optionally used to monitor the burning zone and tire slips) can be seamlessly integrated into one complete thermal image. Detect abnormal operating conditions such as faulty flame position and shape! Optimize and manage kiln maintenance! Extend the operational life of kiln and refractory! Automated kiln and refractory monitoring Visualisation on PC Ethernet TCP/IP interface PC-independent alarm output Analog outputs 3 x 4 – 20mA To ensure reliable operation in even the harshest kiln environments, the MP150 linescanner, which is used in the CS210 thermal imaging system system, is designed with a rugged cast aluminum housing and mounted in a robust stainless-steel enclosure.

Request for a quote

FLUKE PROCESS INSTRUMENTS GMBH

Germany

Thermal imaging system based on the Raytek MP150 infrared linescanner Automatic temperature and quality monitoring in continuous web processes Detect thermal problems early Faster product changes and reduced setup time Communicate with process control system via OPC Reduce scrap APPLICATIONS Plastics, metals, paper, and building industries, combustion prevention, hotspot detection, flat and float glass production, automotive, food processing and numerous other industrial applications FEATURES Onboard Ethernet TCP/IP communication Product specific configurations or “recipes” Custom measurement sectors Optional analog and digital outputs for each sector Analog outputs 3 x 4 – 20mA PC-independent alarm output Visualisation on PC Software supports English, German, French, Finnish, Dutch and Italian languages

Request for a quote