SETNAG - EXPERT EN ANALYSE D'OXYGENE - The oxygen analysis people

France

Manufacturer/ Producer

SETNAG - EXPERT EN ANALYSE D'OXYGENE

France

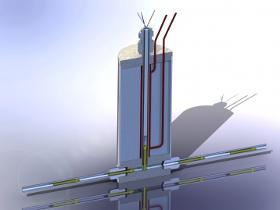

MicroPoas® is a sensor with a built-in metal reference, meaning that it does not require any reference gas. This gives several advantages: miniaturization, autonomy towards outside environment, high metrological performances, use in extreme environments (extreme temperature and pressure), longer life span, etc. Mastered technique and technology Miniaturization: the smallest of all zirconia sensors - standard diameter: 3mm (2mm for special application) - 10mm long Autonomy: very high measurement accuracy - Specific to gaseous oxygen - Inside metal reference: made of a metal and its oxide, it is placed inside the zirconia sleeve - Built-in thermocouple (K or S type): the real MicroPoas® temperature is taken into account. Unique features - Reference gas becomes unnecessary - Very high resistance to thermal shocks - Longer life span - Assemblies fit...

Request for a quote

SETNAG - EXPERT EN ANALYSE D'OXYGENE

France

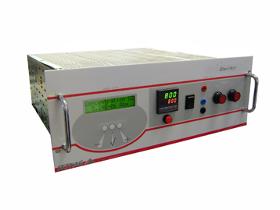

Brand : SETNAG MicroPoas® : different assemblies are available Assembly No. Tube outer diameter Tube length MicroPoas diameter Type of wire 3 2.8 mm 105, 250 or 450mm 3 mm Extension (10mm) 5 5.5mm 105, 250, 450 or 700mm 3 mm Extension (10mm) 6 5.5mm 105, 250, 450 or 700mm 3 mm Compensation (1m) 7 4mm 105, 250 or 450mm 2 mm Compensation (1m) 8 4mm 105, 250 or 450mm 2 mm Extension (10mm) 9 2 or 2.2mm 170mm 2 mm Extension (10mm) This assemblies are available in standard version (500 to 900°C 1), and in high temperature version (600 to 1050°C 1). both of them include a S thermocouple for measuring the temperature. 1 depending on the gas composition, especially for use in highly reducing atmospheres – please contact us for more information The OXYBOX’AIR ® allows acquiring the signals from the MicroPoas ® (cell voltage and thermocouple) and calculating the partial presssure. Information can then be collected via the digital RS485 output...

Request for a quote

SETNAG - EXPERT EN ANALYSE D'OXYGENE

France

Measurement of oxygen in combustion gases and in incineration gases. QAL1 compliant (EN14181) Brand : SETNAG ADVANTAGES No need for reference gas: use of the MicroPoas® Maximum gas temperature: up to 1300° C continuously, depending on the version No sensitive parts and no hot spot inside the duct Free circulation of the gases you analyse "Detachable" probe tubes: easy to dismantle and replace for simple and cost-effective maintenance. Limited maintenance and service operations: easy probe tube cleaning with compressed air and/or fast dismantling. MEASUREMENT PRINCIPLE The gases own speed inside the duct enables them to flow freely up to the sensor where they are analysed. They pass through co-circular tubes the length of which can be adapted to the dimensions of the duct. The electronic system collects the temperature and voltage signals from the MicroPoas®, and gives the oxygen concentration. EXAMPLES OF APPLICATIONS Control of combustion in power generation, district heating...

Request for a quote

SETNAG - EXPERT EN ANALYSE D'OXYGENE

France

Measurement of oxygen in combustion gases (specially dedicated to natural gas boilers) Brand : SETNAG ADVANTAGES : No need for reference gas: use of the MicroPoas® Communication: analogue outputs 4-20 mA and RS485 as standard Integrated safety: 3 alarms Control of operating costs, virtually maintenance-free Fast set-up (sensor and electronic system in a single apparatus) Simple and intuitive use MEASUREMENT TECHNIQUE The gases own speed inside the duct enables them to flow freely up to the sensor where they are analysed. They pass through co-circular tubes the length of which can be adapted to the dimensions of the duct. The electronic system collects the temperature and voltage signals from the MicroPoas®, and gives the oxygen concentration. EXEMPLES OF APPLICATIONS Control of combustion in power generation, district heating operations Control of processes... OXYBOX'ATK

Request for a quote

SETNAG - EXPERT EN ANALYSE D'OXYGENE

France

Measurement of oxygen in combustion gases Control of processes and measurement of emissions. QAL1 compliant (EN14181) Brand : SETNAG ADVANTAGES : No need for reference gas: use of the MicroPoas® Semi in situ measurement (excellent reliability) Free circulation of the gases you analyse Easy and fast set-up Limited and cost-effective service and maintenance operation MEASUREMENT TECHNIQUE The S24N-2020 analyser fits CEM systems Oxygen measurement on wet gas (direct connection at heated hose outlet) Oxygen measurement on dry gas (after sample conditioning) EXAMPLES OFAPPLICATIONS Power generation, district heating operations... Incineration of industrial and domestic waste Steam production Steel works VOC incineration Control of processes...

Request for a quote

SETNAG - EXPERT EN ANALYSE D'OXYGENE

France

Measurement of oxygen in gases Process control Brand : SETNAG ADVANTAGES : No need for reference gas: use of the MicroPoas® Semi in situ measurement (excellent reliability) Free circulation of the gases Easy and fast set-up Almost maintenance free, cost effective service MEASUREMENT TECHNIQUE The S24N-2020 analyser fits CEM systems Oxygen measurement on wet gas (direct connection at heated hose outlet) Oxygen measurement on dry gas (after sample conditioning) EXAMPLES OF APPLICATIONS Power generation, district heating operation... Incineration of industrial and domestic waste Steam production Steel works VOC incineration Control of processes...

Request for a quote

SETNAG - EXPERT EN ANALYSE D'OXYGENE

France

In situ oxygen probe Brand : SETNAG ADVANTAGES : Excellent response time, thanks to the MicroPoas® miniaturized zirconia sensor. Increased reliability and easy set-up as no reference gas is required. The excellent measurement reproducibility ensures perfect control of your process. MEASUREMENT TECHNIQUE / RUNNING The TTH sensor is directly plunged in the gases for analysis. TTH can be used from 500 to 1050°C depending on the model. The MicroPoas® signals are collected by one of our electronic systems (ATS2020 or Oxybox’Air) which will display and/or send a 4-20mA output signal proportional to the measured oxygen concentration. EXAMPLES OF APPLICATIONS Heat treatment Control of combustion Waste incineration Crematorium

Request for a quote

SETNAG - EXPERT EN ANALYSE D'OXYGENE

France

Analysis and measurement of trace oxygen inside pure and inert gases Brand : SETNAG ADVANTAGES : Wide measurement range: from 0.01ppm to 25% over a single range Easy set-up and fast response time: use of the MicroPoas®. Simple and user-friendly system Almost maintenance-free Alarm monitoring as standard MEASUREMENT TECHNIQUE The gas freely flows in the analyser (it can also be forced) and passes over the MicroPoas®. Thanks to the built-in metal reference of our zirconia sensor; measurement is in no way influenced by the environment. Therefore, reliability and reproducibility are improved. EXAMPLES OF APPLICATIONS Air separation Control of particular atmospheres Tightness control Heat treatment Control of inerting JC24V

Request for a quote

SETNAG - EXPERT EN ANALYSE D'OXYGENE

France

The oxygen pump gauge has been designed to generate and control atmospheres containing oxygen Brand : SETNAG ADVANTAGES Continuous measurement of the generated atmosphere between 10 -35 and 0.25atm Use of different kinds of carrier gases, at various concentrations Limited costs as a single gas is required Very high measurement accuracy: use of the MicroPoas® Low gas consumption: necessary flow 1 to 13 l/h Control of the applied voltage and current Maintenance-free MEASUREMENT TECHNIQUE The oxygen pump set uses the principle of ionic conduction of zirconia. When a continuous voltage is applied across the zirconia tube terminals an oxygen flow is created. The quantity of oxygen in the gas circulating inside the zirconia tube will increase, or decrease, according to how the voltage is applied. The partial pressure is measured by the MicroPoas™. EXAMPLES OF APPLICATIONS Study of reactional mixtures Gen'Air

Request for a quote

SETNAG - EXPERT EN ANALYSE D'OXYGENE

France

Oxygen partial pressure measurement Brand : SETNAG ADVANTAGES Wide measurement range: from 10 -35 to 0.25atm. Excellent response time thanks to the MicroPoas® miniaturized zirconia sensor. Easy and fast set-up MEASUREMENT AND WORKING TECHNIQUE The reactional mixture to be analysed freely circulates through the analyser, and the MicroPoas® delivers a signal which reflects the equilibrium oxygen partial pressure in the gas. Jok’Air-2060 can measure from 10 -35 to 0.25atm. EXAMPLES OF APPLICATIONS Materials characterization Nuclear research

Request for a quoteManufacturer/ Producer

Technopole de Château-Gombert

22-26 rue John Maynard Keynes

13013 Marseille - France

europages also recommends

A selection of companies related to the activity:

A selection of products that might interest you

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

DIGIFORCE® 9311 is the new standard in efficient quality control. The pioneering force/displacement controller delivers rapid, precise evaluation results for applications that demand both high quality and high productivity. The smart performance features and intelligent hardware make test equipment quicker to set up, easier to use and capable of automatic integration in modern production systems. This unrivalled product specification gives businesses the added security and dependability they need for increasingly complex production processes. The DIGIFORCE® 9311 monitors processes in which precisely defined functional relationships need to be demonstrated between two measured quantities of the process. For instance when recording and monitoring processes such as press-insertion, joining, riveting, stamping or caulking, reliable quality control depends on synchronous and high-speed acquisition of measured values combined with analysis based on versatile evaluation elements.

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

The SENSORMASTER 9163 covers a wide range of applications in which process values need to be measured, displayed, analyzed and transferred to higher-level control systems. Typical applications include measuring geometric values in production, for instance differential measurements, or testing material properties in the laboratory. The measured values can be transferred via USB, RS232 or analog output. Features: — For force, pressure or torque measurements using strain gauge sensors — For position or angle measurement using potentiometric or DC/DC sensors — For temperature measurement using Pt 100 sensors or thermocouples — Optional multi-channel model — Optional Profibus or serial interface — 0.1 % measurement accuracy plus sensor-specific linearization — Range of mathematical functions (e.g. differential measurement) — OK/NOK feedback on multi color display and via 4 alarm limit outputs — High sampling rate (500/sec.)

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

Based on its specifications, this device can be used in various applications. It is especially suitable for resistance measurement on insulating materials such as e.g. cable insulations, foils, textiles, surfaces, insulating liquids,etc. With a test voltage of 45 V, 100 V, 250 V and 500 V the device fulfi ls most test specifi cations such as e.g. DIN 51953, 53482 and 54345. The guard switching allows single resistance measurements in a triangle wiring. This could be e.g. a two line cable with common shield or the measurement of insulating materials on a guardring measurement cell. The selection of the measurement range is done manually or automatically. Fast subsequent measurements can be realized by the internal limit value indicator. When the measured value exceeds the limit the limit value indicator switches and activates a potential-free relay output. The megohmmeter RESISTOMAT® model 24508 is the right instrument for its use in laboratory as well as in industrial applications.

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

Automatic inspection and test unit: Automatic choice of measuring ranges from 200 μΩ to 20 kΩ Resolution up to 1 nΩ Standard interfaces IEEE488, RS232, RS485, (USB and Ethernet option) Checking of tolerances, classifi cation with statistics Highest measuring accuracy: Measuring error ≤ 0.01 % Future-orientated measuring method with thermal e.m.f. compensation. High level of stability due to constant comparisons with internal reference values. Inductive probes: Current regulation results in voltage-free disconnection, calculation of cooling curves of coils. Menu control: Setting for measuring current entry for absolute or relative limits, classifi cation with statistics, bar display for calibration of measuring probes, determination of resistivity, and many other functions. The operation of the measuring section of the RESISTOMAT® model 2304, 2305 high-precision inspection and test unit is based on an upgraded 4-wire design.

Request for a quoteRequest for quotes

Create one request and get multiple quotes form verified suppliers.

- Only relevant suppliers

- Data privacy compliant

- 100% free