- europages

- >

- Fabrics for technical use

- >

- SGL TECHNOLOGIES GMBH

SGL TECHNOLOGIES GMBH

Germany

Manufacturer/ Producer

SGL TECHNOLOGIES GMBH

Germany

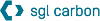

Our SIGRATEX textile materials form the ideal basis for the production of high-quality fiber-reinforced plastics. They are suitable for a wide variety of processing technologies such as prepreg production, wet lamination, infusion, wet pressing, and RTM and they open up new possibilities in the serial production of fiber-reinforced components. SIGRATEX textile materials make composite materials extremely light, strong and stiff. Extensive product portfolio We offer an extensive portfolio of high-quality non-crimp fabrics, woven fabrics, woven tapes, non-wovens, and stacks based on carbon, glass, and aramid fibers. We have the right material for your application.

Request for a quote

SGL TECHNOLOGIES GMBH

Germany

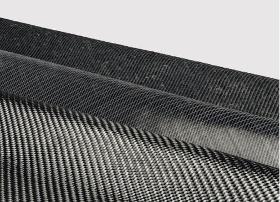

SIGRATEX non-crimp fabrics (NFC) are high-quality textile reinforcing materials that we produce for our customers from our SIGRAFIL 50k carbon fiber or from glass fibers. Our portfolio includes uni- and multiaxial fabrics, which we offer in various fiber orientations, areal weights, widths, and stitching types.

Request for a quote

SGL TECHNOLOGIES GMBH

Germany

In our weaving facility, we produce a wide range of SIGRATEX woven fabrics and tapes. We use 1k, 3k, 6k, 12k, and 24k carbon fiber tows as the material basis. In hybrid woven fabrics, we also process glass and aramid fibers.

Request for a quote

SGL TECHNOLOGIES GMBH

Germany

Based on carbon and glass fibers, we produce isotropic non-wovens with different fiber orientations and lengths. The non-wovens are made of 100% recycled materials.

Request for a quotePortrait of the SGL Carbon site in Wackersdorf: The SGL Carbon site in Wackersdorf, in the Upper Palatinate, is part of the Carbon Fibres division. Here, about 140 highly-qualified staff deal with the production of mats and non-woven fabrics from carbon, glass or natural fibres. The diverse product range of over 150 product variants is rounded off with the subsequent process step of stacking. This involves superimposing different layers of mats, cutting them into stacks and joining them, all per customer specification. These stacks are then processed by the customer to produce preforms or finished components. Every year, SGL Carbon produces over 8, 000 tons of carbon, glass or natural fibre mats at the Wackersdorf site. The site also boasts three stacking machines with a capacity of over 2 million stacks per year. The products from Wackersdorf are used in a wide range of sectors, albeit primarily in the automotive and aerospace industries. Several recycling facilities serve to recycle the production waste that cannot be avoided in the process. All the facilities are powered by green electricity. Our SIGRATEX textile materials are the ideal basis for producing high-quality, fibre-reinforced plastics. They are suitable for a wide range of processing operations.

Website

Documents

Videos

Manufacturer/ Producer

Werner-von-Siemens-Strasse 18

86405 Meitingen - Germany

Company info

Key figures

-

- Company headcount

- > 500

Organisation

-

- Year established

- 1878

-

- pages.epage-home.site-status

- Registered office – Parent company

-

- Main activity

- Manufacturer/ Producer

Business info

Trading areas

- International

Delivery areas

Terms of delivery (incoterms)

- Purchaser

- Shared

- Vendor

Activities of SGL TECHNOLOGIES GMBH

- Fabrics for technical use

- Bands, woven - industrial

- Fabrics, nonwoven

- fibre optics

- Aramid fibres

- fibre-reinforced plastics

- Technical threads and fabrics

- Fibres

- natural fibres

- carbon fibres