SINOP SMP - Our goal: Faster, better, more helpful

Czech Rep.

Manufacturer/ Producer

SINOP SMP

Czech Rep.

Our know-how and expertise won in 20+ years of experience working with sheet metals enable us to help you optimize your product. The clever bending instead of assembling of more parts together? Forming the thread or other elements directly on punching machine in order to avoid expensive machining? Unnecessary grinding thanks to welding procedure optimization? Those are just examples which may reduce the manufacturing costs of your products. We are happy to assist you on your way to optimize them.

Request for a quote

SINOP SMP

Czech Rep.

Designing of own jigs and fixtures inhouse Manufacturing of fixtures inhouse Types of fixtures Welding fixtures Manufacturing and clamping fixtures Controlling and assembling fixtures

Request for a quote

SINOP SMP

Czech Rep.

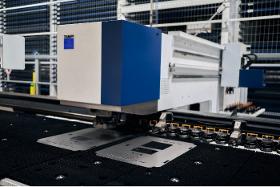

Technology of CNC punching offers unbeatable accuracy, reliability and productivity. Our CNC punching machines gives us various processing capabilities such as thread forming, profiling and much more. Our machine TruPunch 5000 is equipped with Sheet Master – the automated loading and unloading system enabling the unrivalled process efficiency. Efficient punching of holes and shapes Threading, shape forming and punching of complex contours The active die guarantees scratch-free surface Automatic feeding of metal sheets and unloading of products with automated Sheet Maste Mild steel up to 5 mm, stainless steel up to 4 mm Maximal size of the metal sheet 3000 x 1500 mm

Request for a quote

SINOP SMP

Czech Rep.

Utilization of the most modern technologies including CO2 and solid-state (Fiber laser) laser cutting machines gives us technological capabilities to precisely cut metal sheets and process parts of complex geometries. Especially the Fiber laser machines allow cutting with very high speed and maintaining high level of accuracy and precision. Cutting with utilization of CO2 or solid-state laser source Solid-state laser for cutting of thin sheets CO2 laser for cutting without burrs Mild steel up to 25 mm, stainless steel up to 20 mm Aluminum up to 12 mm, brass and cupper up to 5 mm Maximal size of the metal sheet 3000 x 1500 mm

Request for a quote

SINOP SMP

Czech Rep.

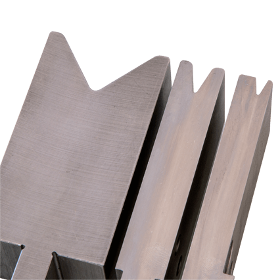

Die Bending with Press Brake Custom manufacturing as well as large volume production Software simulation of bending feasibility CNC programming of press brakes from office “Z” bend, flattened hems and radius bends Bending flexibility thanks to 6-axis backgauge Maximal bending length 3000 m, maximal sheet thickness 10 mm

Request for a quote

SINOP SMP

Czech Rep.

For high volume production, but also for smaller batches Automated bending process Automatic correction based on the measured sheet thickness Automatic correction based on the measured value of spring back High precision and repeatability Maximal bending length 2180 mm, maximal sheet thickness 3 mm/li>

Request for a quote

SINOP SMP

Czech Rep.

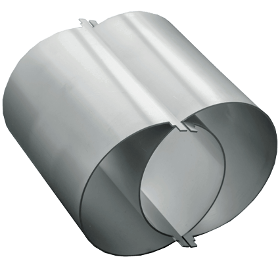

Individual and serial production Rolling on the plate rolling machine with four actuated rolls Roll diameter 70 mm CNC control Feasibility to roll intricate elliptical shapes Maximal work length 1040 mm, maximal sheet thickness 2 mm

Request for a quote

SINOP SMP

Czech Rep.

Since 2011 we are proud to have robotic laser welding technology (currently 3 welding cells) at our disposal. The laser beam is generated with the solid-state laser source TruDisk with a maximal power output of 4 kW. Laser welding stands for the unrivalled welding productivity and a low heat application. This guarantees a minimal distortion and an outstanding appearance of the weld seam. The clamping fixtures for robotic welding are developed and produces in house. Very small heat affected zone resulting in the low distortion of the components Smooth and symmetrical weld seam High process stability and high welding speed Outstanding weld seam quality with a minimal or no necessity for an additional surface treatment Fixture design and development in house

Request for a quote

SINOP SMP

Czech Rep.

For high volume production, but also for smaller batches MIG/MAG welding TIG (WIG) welding with wire feeding MIG soldering with an additional material CuSi Fixture design and development in house

Request for a quote

SINOP SMP

Czech Rep.

MIG/MAG welding, reference number of 131/135 TIG(WIG) welding, reference number of 141 and 142 MIG soldering with an additional material CuSi Materials: Steel, Stainless steel and Aluminum Professional power sources by company Fronius Welding tables by company Siegmund

Request for a quoteManufacturer/ Producer

Budějovická 466

370 01 Homole - Czech Rep.