STOROPACK HANS REICHENECKER GMBH - perfect protective packaging

Germany

Manufacturer/ Producer

STOROPACK HANS REICHENECKER GMBH

Germany

IT'S WELL EQUIPPED WHEN EVEN THE ACCESSORIES ARE FIRST CLASS. Storopack has everything you need for the temperature-controlled shipping of life science, medico-technical, or biotechnology products. In addition to pre-qualified packaging and system solutions, our product portfolio also includes accessories for our temperature-controlled protection packaging. Cooling agents for every purpose: Our gel packs provide reliable cooling throughout the entire time the goods are being transported. They are available in five different sizes, are reusable, and represent an economical alternative to accumulators or foam bricks. You could also opt for our reusable accumulators, which come in two sizes and can be used again as often as needed. Here you have the choice between H20 or PCM accumulators for different temperature ranges. Control is better: Storopack supplies two different temperature data loggers for monitoring the temperature of goods during transportation – “tempmate.® S1 V2”...

Request for a quote

STOROPACK HANS REICHENECKER GMBH

Germany

EPS IS TAILORED PACKAGING. At Storopack, the three letters, EPS, are a guarantee for reliable product protection. There’s good reason why we use the material in our tailored packaging solutions. EPS, which stands for “expanded polystyrene” and is more commonly referred to as styrofoam, combines several benefits all at once: it’s very lightweight, exceptionally pressure-resistant, and absorbs next to no water. Our transport packing made from EPS is therefore optimal for delivering sensitive products such as computers, TVs, refrigerators, and other technical devices safely to their destination. To ensure maximum product safety, Storopack produces the packaging, which adapts specifically to transporting goods with customized geometry. EPS is 98 percent air, fully recyclable, and can be used over and over again.

Request for a quote

STOROPACK HANS REICHENECKER GMBH

Germany

EPP MEANS BEING ABLE TO HANDLE HEAVY LOADS EASILY. Expanded polypropylene (EPP) is the ideal basis for a tailored, reusable packaging solution, as the extremely durable material boasts high specific energy absorption. EPP can withstand strain such as shocks and even repeated impacts during transport – the material remains fully functional without any discernible damage and reliably protects the packaged goods. Storopack’s tailored, stackable EPP packaging can be used for solutions with high circulation, such as cargo carriers for the transport of sensitive parts in the automotive industry. An intelligent and, at the same time, simple reusable solution, available in a variety of colors and completely recyclable.

Request for a quote

STOROPACK HANS REICHENECKER GMBH

Germany

NEOPOR® MEANS OPTIMAL INSULATION. As soon as packaging not only has to protect, but also insulate, Neopor® is used, a version of Styropor® that contains graphite. The expanded foam features impressively low thermal conductivity combined with high compressive resistance, providing the basis for energy-efficient solutions. Among other things, Storopack uses Neopor® to manufacture insulating boxes for packaging and shipping temperature-sensitive products such as food and medicines. Insulating boxes and system solutions made of Neopor® ensure that goods are always kept within a set temperature range, independently of the active cooling system in the laboratory, warehouse, or truck. Thanks to outstanding heat and cold insulation properties, high compressive resistance, reliable shock absorption, low weight, and guaranteed low moisture absorbency, Neopor® packaging is not only tailor-made for products, but also secure and temperature-resistant.

Request for a quote

STOROPACK HANS REICHENECKER GMBH

Germany

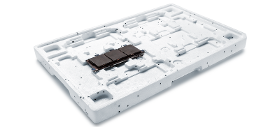

PIOCELAN® MEANS OPTING FOR OUTSTANDING MECHANICAL PROPERTIES. Piocelan® is an intelligent mix of polystyrene (EPS) and polyethylene (PE) or EPS and polypropylene (PP) and combines the advantages of both: It has the low density of EPS, while featuring the outstanding chemical resistance and shock absorption properties of PE respectively PP. It is also incredibly robust and wear-resistant – characteristics that make Piocelan® molded parts the ideal solution for demanding conditions, frequent turnarounds, and other special requirements. The material therefore forms the basis of the Storopack trays. They provide protection during the transportation of sensitive electronic and technical components and can be used several times. Thanks to their outstanding ability to absorb energy, these reusable packaging products effectively protect the transported goods from damage while being transported.

Request for a quote

STOROPACK HANS REICHENECKER GMBH

Germany

EPS MEANS OPTING FOR MAXIMUM FREEDOM. Technical molded parts made of expanded polystyrene (EPS) are the material of choice when it comes to good moldability, light weight, and outstanding insulation. EPS is ideal for the lost foam casting process. This involves embedding an EPS foam model of the desired component within a casting chamber in molding sand and dissolving it by pouring in molten metal. Compared to other processes, this affords greater design freedom when creating the cast parts, because neither built-in parts nor connections are necessary. As such, even complex cast components can be produced easily and particularly inexpensively. EPS also serves the construction industry well: Due to their very low thermal conductivity, technical molded parts are used as insulation elements and panels for underfloor heating systems. They can also be used as formwork elements. Whether for individual geometries or technically demanding structures, EPS makes it possible.

Request for a quote

STOROPACK HANS REICHENECKER GMBH

Germany

EPP CAN WITHSTAND HEAVY STRAIN. Technical molded parts made of expanded polypropylene (EPP) are indispensable in a number of industries – in car manufacturing, for example. Thanks to their outstanding energy-absorbing properties, EPP parts improve passive safety and provide better protection for vehicle occupants. Accordingly, they are used to make fenders, headrests, and other impact absorbers. EPP can absorb even more energy when used in combination with metal. One secondary benefit is the low weight of the innovative material: EPP molded parts thus cut fuel consumption and make cars more eco-friendly. Due to the fact that it can be precisely shaped, EPP also cuts a good figure elsewhere – as a sun visor, paneling, or a toolbox for precisely accommodating breakdown sets. Its extraordinary insulating ability is also the reason why notable manufacturers in the heating and air conditioning industry use EPP molded parts from Storopack for their products.

Request for a quote

STOROPACK HANS REICHENECKER GMBH

Germany

NEOPOR® MEANS OPTIMAL INSULATION. Neopor® comes into its own when perfect insulation is called for. The expanded foam is a version of Styropor® that contains graphite with insulation properties that are ten percent better. The very low thermal conductivity combined with high compressive resistance makes it the perfect material for technical molded parts. Storopack uses Neopor® to manufacture insulation elements for building sections such as the roof and walls as well as perimeter bases and panels for laying underfloor heating systems. Up to 70 percent of heat energy can be saved with Neopor® thermal insulation compared to homes with no exterior insulation. Storopack products made of Neopor® are used in heating and air conditioning applications for insulating boilers, pumps, and heating controls and as housing for modern home ventilation systems. The technical molded parts can be expanded to optimally fit around contours so that no heat is lost.

Request for a quote

STOROPACK HANS REICHENECKER GMBH

Germany

PIOCELAN® MEANS OPTING FOR OUTSTANDING MECHANICAL PROPERTIES. As a material, Piocelan® is an intelligent combination of polystyrene (EPS) and polyethylene (PE) or EPS and polypropylene (PP), bringing together the best of both worlds: Piocelan® features the low density of EPS and the exceptional chemical resistance and shock absorption of PE respectively PP. It’s especially robust and wear-resistant – characteristics that make Piocelan® molded parts the ideal solution for difficult conditions, including high circulation, and other special requirements.

Request for a quote

STOROPACK HANS REICHENECKER GMBH

Germany

STURDY AND TEAR-RESISTANT – PAPERplus® CLASSIC The PAPERplus® Classic paper cushioning system is the ideal protective packaging solution for heavy weight products. With paper pads, two ply paper, even heavy products can be securely blocked and braced in cartons and cushioned all around. At the press of a button, PAPERplus® Classic produces robust, tear-resistant, but also flexible and highly malleable paper cushioning. Storopack customers can choose between the two paper types PAPERplus® Standard and PAPERplus® GE as well as recycled paper.

Request for a quoteManufacturer/ Producer

Untere Rietstr. 30- 32

72555 Metzingen - Germany

europages also recommends

A selection of companies related to the activity:

A selection of products that might interest you

SEKIL OFSET A.S

Turkey

Possible Options: Paper: Brown or White Food Grade Paper Printing: CMYK Finishing: Varnish Window: With or Without as you choose These pouches are a great solution for hygiene in your cafes, restaurants, buffets, and anything related to cookies, nuts, donuts, other foods/fast foods and takeaway orders. Let your brand wander the world!

Request for a quote

SEKIL OFSET A.S

Turkey

Possible Options: Paper: Brown or White Food Grade Paper Printing: CMYK Finishing: Varnish Window: With or Without as you choose These pouches are a great solution for hygiene in your cafes, restaurants, buffets, and anything related to cookies, nuts, donuts, other foods/fast foods and takeaway orders. Let your brand wander the world!

Request for a quote

SEKIL OFSET A.S

Turkey

Possible Options: Paper: Brown or White Food Grade Paper Printing: CMYK Finishing: Varnish Window: With or Without as you choose These pouches are a great solution for hygiene in your cafes, restaurants, buffets, and anything related to cookies, nuts, donuts, other foods/fast foods and takeaway orders. Let your brand wander the world!

Request for a quote

SEKIL OFSET A.S

Turkey

Possible Options: Paper: Brown or White Food Grade Paper Printing: CMYK Finishing: Varnish Window: With or Without as you choose These pouches are a great solution for hygiene in your cafes, restaurants, buffets, and anything related to cookies, nuts, donuts, other foods/fast foods and takeaway orders. Let your brand wander the world!

Request for a quoteRequest for quotes

Create one request and get multiple quotes form verified suppliers.

- Only relevant suppliers

- Data privacy compliant

- 100% free