- europages

- >

- Clutches

- >

- TAS SCHÄFER GMBH

- >

- products

TAS SCHÄFER GMBH - a reliable partner for shaft-hub connections

Germany

Manufacturer/ Producer

TAS SCHÄFER GMBH

Germany

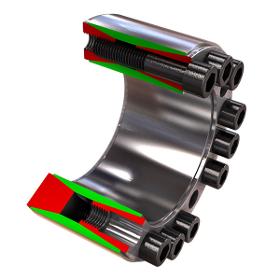

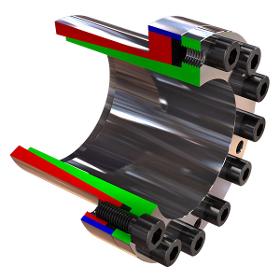

The main function of a locking assembly is the safe connection of a shaft to a hub by means of friction. For example, between a shaft and a gear hub. The locking assembly creates a play-free connection by expanding between the shaft and the hub. This type of connection is used mainly for transmitting torque. It is installed by inserting the locking assembly between the components and the subsequent tightening of the screws. By using conical surfaces, the outer diameter increases and the inner diameter reduces. Radial pressure is built up. The clamping forces are provided and controlled by the screws (force-controlled). This allows the direct compensation of the clearance between shaft and hub. The supplied locking devices are ready for installation. To achieve proper operation with a sufficiently high coefficient of friction, the contact surfaces between shaft and hub must be clean and slightly oiled. Machine oil must be used as a lubricant. The functional surfaces of the locking...

Request for a quote

TAS SCHÄFER GMBH

Germany

The main function of a locking assembly is the safe connection of a shaft to a hub by means of friction. For example, between a shaft and a gear hub. The locking assembly creates a play-free connection by expanding between the shaft and the hub. This type of connection is used mainly for transmitting torque. It is installed by inserting the locking assembly between the components and the subsequent tightening of the screws. By using conical surfaces, the outer diameter increases and the inner diameter reduces. Radial pressure is built up. The clamping forces are provided and controlled by the screws (force-controlled). This allows the direct compensation of the clearance between shaft and hub. The supplied locking devices are ready for installation. To achieve proper operation with a sufficiently high coefficient of friction, the contact surfaces between shaft and hub must be clean and slightly oiled. Machine oil must be used as a lubricant. The functional surfaces of the locking...

Request for a quote

TAS SCHÄFER GMBH

Germany

The main function of a locking assembly is the safe connection of a shaft to a hub by means of friction. For example, between a shaft and a gear hub. The locking assembly creates a play-free connection by expanding between the shaft and the hub. This type of connection is used mainly for transmitting torque. It is installed by inserting the locking assembly between the components and the subsequent tightening of the screws. By using conical surfaces, the outer diameter increases and the inner diameter reduces. Radial pressure is built up. The clamping forces are provided and controlled by the screws (force-controlled). This allows the direct compensation of the clearance between shaft and hub. The supplied locking devices are ready for installation. To achieve proper operation with a sufficiently high coefficient of friction, the contact surfaces between shaft and hub must be clean and slightly oiled. Machine oil must be used as a lubricant. The functional surfaces of the locking...

Request for a quote

TAS SCHÄFER GMBH

Germany

The main function of a locking assembly is the safe connection of a shaft to a hub by means of friction. For example, between a shaft and a gear hub. The locking assembly creates a play-free connection by expanding between the shaft and the hub. This type of connection is used mainly for transmitting torque. It is installed by inserting the locking assembly between the components and the subsequent tightening of the screws. By using conical surfaces, the outer diameter increases and the inner diameter reduces. Radial pressure is built up. The clamping forces are provided and controlled by the screws (force-controlled). This allows the direct compensation of the clearance between shaft and hub. The supplied locking devices are ready for installation. To achieve proper operation with a sufficiently high coefficient of friction, the contact surfaces between shaft and hub must be clean and slightly oiled. Machine oil must be used as a lubricant. The functional surfaces of the locking...

Request for a quote

TAS SCHÄFER GMBH

Germany

The main function of a locking assembly is the safe connection of a shaft to a hub by means of friction. For example, between a shaft and a gear hub. The locking assembly creates a play-free connection by expanding between the shaft and the hub. This type of connection is used mainly for transmitting torque. It is installed by inserting the locking assembly between the components and the subsequent tightening of the screws. By using conical surfaces, the outer diameter increases and the inner diameter reduces. Radial pressure is built up. The clamping forces are provided and controlled by the screws (force-controlled). This allows the direct compensation of the clearance between shaft and hub. The supplied locking devices are ready for installation. To achieve proper operation with a sufficiently high coefficient of friction, the contact surfaces between shaft and hub must be clean and slightly oiled. Machine oil must be used as a lubricant. The functional surfaces of the locking...

Request for a quote

TAS SCHÄFER GMBH

Germany

The main function of a locking assembly is the safe connection of a shaft to a hub by means of friction. For example, between a shaft and a gear hub. The locking assembly creates a play-free connection by expanding between the shaft and the hub. This type of connection is used mainly for transmitting torque. It is installed by inserting the locking assembly between the components and the subsequent tightening of the screws. By using conical surfaces, the outer diameter increases and the inner diameter reduces. Radial pressure is built up. The clamping forces are provided and controlled by the screws (force-controlled). This allows the direct compensation of the clearance between shaft and hub. The supplied locking devices are ready for installation. To achieve proper operation with a sufficiently high coefficient of friction, the contact surfaces between shaft and hub must be clean and slightly oiled. Machine oil must be used as a lubricant. The functional surfaces of the locking...

Request for a quote

TAS SCHÄFER GMBH

Germany

The main function of a locking assembly is the safe connection of a shaft to a hub by means of friction. For example, between a shaft and a gear hub. The locking assembly creates a play-free connection by expanding between the shaft and the hub. This type of connection is used mainly for transmitting torque. It is installed by inserting the locking assembly between the components and the subsequent tightening of the screws. By using conical surfaces, the outer diameter increases and the inner diameter reduces. Radial pressure is built up. The clamping forces are provided and controlled by the screws (force-controlled). This allows the direct compensation of the clearance between shaft and hub. The supplied locking devices are ready for installation. To achieve proper operation with a sufficiently high coefficient of friction, the contact surfaces between shaft and hub must be clean and slightly oiled. Machine oil must be used as a lubricant. The functional surfaces of the locking...

Request for a quote

TAS SCHÄFER GMBH

Germany

The main function of a locking assembly is the safe connection of a shaft to a hub by means of friction. For example, between a shaft and a gear hub. The locking assembly creates a play-free connection by expanding between the shaft and the hub. This type of connection is used mainly for transmitting torque. It is installed by inserting the locking assembly between the components and the subsequent tightening of the screws. By using conical surfaces, the outer diameter increases and the inner diameter reduces. Radial pressure is built up. The clamping forces are provided and controlled by the screws (force-controlled). This allows the direct compensation of the clearance between shaft and hub. The supplied locking devices are ready for installation. To achieve proper operation with a sufficiently high coefficient of friction, the contact surfaces between shaft and hub must be clean and slightly oiled. Machine oil must be used as a lubricant. The functional surfaces of the locking...

Request for a quote

TAS SCHÄFER GMBH

Germany

The main function of a locking assembly is the safe connection of a shaft to a hub by means of friction. For example, between a shaft and a gear hub. The locking assembly creates a play-free connection by expanding between the shaft and the hub. This type of connection is used mainly for transmitting torque. It is installed by inserting the locking assembly between the components and the subsequent tightening of the screws. By using conical surfaces, the outer diameter increases and the inner diameter reduces. Radial pressure is built up. The clamping forces are provided and controlled by the screws (force-controlled). This allows the direct compensation of the clearance between shaft and hub. The supplied locking devices are ready for installation. To achieve proper operation with a sufficiently high coefficient of friction, the contact surfaces between shaft and hub must be clean and slightly oiled. Machine oil must be used as a lubricant. The functional surfaces of the locking...

Request for a quote

TAS SCHÄFER GMBH

Germany

The main function of a locking assembly is the safe connection of a shaft to a hub by means of friction. For example, between a shaft and a gear hub. The locking assembly creates a play-free connection by expanding between the shaft and the hub. This type of connection is used mainly for transmitting torque. It is installed by inserting the locking assembly between the components and the subsequent tightening of the screws. By using conical surfaces, the outer diameter increases and the inner diameter reduces. Radial pressure is built up. The clamping forces are provided and controlled by the screws (force-controlled). This allows the direct compensation of the clearance between shaft and hub. The supplied locking devices are ready for installation. To achieve proper operation with a sufficiently high coefficient of friction, the contact surfaces between shaft and hub must be clean and slightly oiled. Machine oil must be used as a lubricant. The functional surfaces of the locking...

Request for a quoteManufacturer/ Producer

Osterfeldstraße 75

58300 Wetter - Germany

europages also recommends

A selection of companies related to the activity:

A selection of products that might interest you

Request for quotes

Create one request and get multiple quotes form verified suppliers.

- Only relevant suppliers

- Data privacy compliant

- 100% free