THERMOTEC PRODUKTIONSGESELLSCHAFT MBH

Germany

Manufacturer/ Producer

THERMOTEC PRODUKTIONSGESELLSCHAFT MBH

Germany

There are two different construction types. It's possible to create a design using a little construction space using the customer's data. The Thermo-Fluid S is connected directly between the oven pipe (or the heating system) and the chimney. The operating temperatures are up to 300°C (standard). The Thermo-Fluid S is low maintance with low pressure drop in the flue gas. Depending on the application you can have energy savings up to 15 %. A bigger construction is the Thermo-Fluid M, which is optimised for utilisation of waste heat from process air, flue gas or exhaust air. An energy yield of up to 1600 kW is possible, whereupon the pressure drop in the process air is less than 1.5 mbar. The pressure drop in water circuit is less than 200 mbar. This Shell and Tube heat exchanger is low maintance using the small type of construction. The Thermo-Fluid M modular and the standard temperatures are up to 300°C too. Both Shell and Tube Heat Exchangers are low maintance. One-off or

Request for a quote

THERMOTEC PRODUKTIONSGESELLSCHAFT MBH

Germany

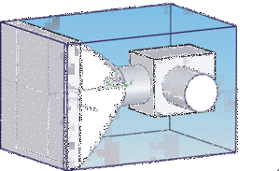

THERMO-GAS Heat Exchangers work optimally if the constant flow of gasses into the heat exchanger is guaranteed. In case of unfavourable assembly conditions, we have made tests and measurements so far in order to optimise stream conditions. Due to the increased requirements on the performance of heat exchangers as well as expanded application areas it has become necessary to achieve optimised results already in the planning phase. This is done by means of a CAD-based simulation which enables the very exact predicition of stream conditions. The performance opportunities of our heat exchangers are used at the best as a result of appropriate installed equipement for flow duct. We would be pleased to provide you with our knowledge also beyond the heat exchanger technology. The precise project In case of a plant for catalytic combustion, the connecting hood to the heat exchanger was significantly shortened due to the assembly of a THERMO-AWT 3-Way Stop valve. After this

Request for a quoteManufacturer/ Producer

Westring 9C

27793 Wildeshausen - Germany