- europages

- >

- Gas filters

- >

- THIELMANN ENERGIETECHNIK GMBH

THIELMANN ENERGIETECHNIK GMBH - GAS FILTRATION & VORWÄRMUNG

Germany

Manufacturer/ Producer

THIELMANN ENERGIETECHNIK GMBH

Germany

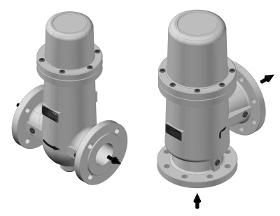

CHARACTERISTICS budget priced short installation length type VZF and ZFG high filtration rate (efficiency) replacable filter cartridges large dust collection area VZF / ZFG dust drain nozzle N3 upstream coarse particle separation 4-way differential pressure connections DVGW certified for all gases according to G260 for non-aggressive special gases many sizes in stock VARIANTS Silumin Cast (VZF/VZEF) Cast Iron (ZFG/ZEFG) Straight Through – VZF/ZFG | DN25 – DN150 Corner Type – VZEF/ZEFG | DN25 – DN100 PN16 | -10 / +70 °C PN16 | -20 / +70 °C PN16 | -40 / +70 °C PN16 | -10 / +150 °C zzgl. TÜV HTB (5 bar g) | -20 / +70°C PN40 | -10 / +70 °C DN25-DN80 PN40 | -20 / +70 °C DN25-DN80 PN40 | -40 / +70 °C DN25-DN80 DNV (maritime) DN25 – DN100, 10 bar g | 0 /+60°C Leaflet: E-5055 Cellular Gas Filter / Type VZF/VZEF/ZFG/ZEFG FUNCTION The gas flows through the inlet nozzle into the filter housing.

Request for a quote

THIELMANN ENERGIETECHNIK GMBH

Germany

ZPZ – VPZ 240°C-Filterelemente (Finalfilter) for cellular gas filters: ZPZ 25 – ZPZ 50 – ZPZ 80 – ZPZ 100 – ZPZ 150, type FFX Efficiency: 99,9 > 1µm In the area of fine dust separation, the gas is cleaned with filter cartridges. Our filter cartridges are all tested according to ISO 12103-01 and proven to be efficient, according to the requirements of the internationally valid “Test Aerosol: SAE-Fine Test Dust”. For special fields of application we can offer and develop special filter elements in order to achieve a performance-fulfilling filtration.

Request for a quote

THIELMANN ENERGIETECHNIK GMBH

Germany

CHARACTERISTICS Efficient dust filtration High deposition rate (efficiency) Filter efficiency tested acc. SAE Fine Test Long service life of the filter elements Upstream coarse particle separation For all gases according to G260 For non-aggressive special gases OPTIONEN Customer-specific design for other regulations (ASME, EN 13445, SVTI, AS1210, PD5500, etc) Customer-specific approvals Customer-specific testings Application for sour gas (NACE) Design for low temperature down to -50 ° C Design pressure up to 300 bar Design temperature up to 250 ° C Customer-specific nozzle arrangement Leaflet (english version in progress): D-5025 Patronenfilter / Typ VPF General Cartridge filters are used to clean gas from dry solid dust particles. The design is carried out as a steel welded construction. FUNCTION The gas flows through the inlet nozzle into the filter housing.

Request for a quote

THIELMANN ENERGIETECHNIK GMBH

Germany

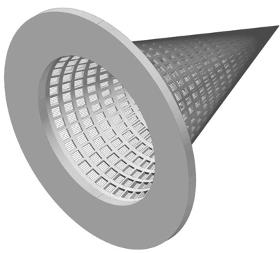

CHARACTERISTICS For clamp mounting into the pipeline Efficient protection of dirt-sensitive system components during commissioning Low differential pressure Easy installation and replacement Material Certificates DIN EN 10204/3.1 for Clamp Collar OPTIONS For DIN and ASME flange connections Design for low temperature down to -50 ° C Design pressure up to 100 bar Stainless steel construction Reverse flow direction GENERAL The starting screen VAS is used for commissioning and starting a system in order to clean gas from coarse soiling such as welding bead, scale, grease, etc. After starting, the starting screen can be removed from the pipeline. The design is carried out as a welding design. FUNCTION The starting screen VAS consists of a supporting basket made of perforated sheet metal with a welded clamping ring. These are galvanized after assembly. On the outside of the support basket a stainless steel wire mesh is welded.

Request for a quoteThielmann Energietechnik GmbH in Kassel is a globally operating specialist for process-technical components for the filtration and preheating of gases. We make your gas-technical systems secure and efficient. With our expertise and focus on quality for individual and customer-specific solutions, we are able to fulfil the most demanding technical requirements. High pressure stages, low- and high-temperature designs and adherence to exceptional guidelines and specifications are our area of expertise. Our key services lie in the design and manufacturing of pressure containers. In addition to these, our offerings include dust filters (gas filters), dust-liquid separators (natural gas separators, coalescers), knock-out drums, cyclone and multi-cyclone separators, heat transfer systems (heat exchangers, natural gas preheaters, natural gas heat exchangers), water bath heaters, condensate tanks, fuel gas performance heaters, absorption silencers, pig traps, gas mixers and the corresponding accessories for monitoring and maintenance.

Website

Company info

Key figures

-

- Company headcount

- 11 – 50

Organisation

-

- Year established

- 1981

-

- pages.epage-home.site-status

- Registered office – Parent company

-

- Main activity

- Manufacturer/ Producer

Business info

Trading areas

- Regional

- National

- European

- International

Delivery areas

Activities of THIELMANN ENERGIETECHNIK GMBH

- Gas filters

- Heat exchangers

- pressure tanks

- dust filters

- hydrogen

europages also recommends

A selection of companies related to the activity:

A selection of products that might interest you

SUVIS GMBH

Germany

Hydro cyclone units are applied in order to separate coarse and fine solid particles from liquids . These type of separators are particularly capable of separating sand, starch, and other finely distributed materials. With hydro cyclones it is possible to separate fine particles online during the process. Hydro cyclone units are used to separate, classify, and to thicken suspensions. Also, these units are used to purify ores and minerals. Also, in fibre technique and paper industry they are applied in purification processes to separate dirt. Hydro cyclones are frequently run in parallel mode. The lay out and design of hydro cyclones are performed empirically similar to the duct cyclones. In the lower flow region of a hydro cyclone an air swirl forms during the separation process, which is not substantially influencing the cyclone flow. Because of the large dimension of the cyclone, wall friction has much more influence on the flow.

Request for a quote

SUVIS GMBH

Germany

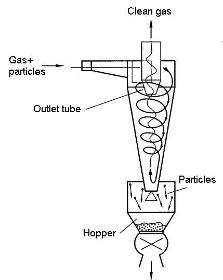

The gas cyclone belongs to the mostly applied technical separators, because it has applicationwise some fundamental advantages. One of them is certainly the fact that its construction does not show any movable components. For the large variety of different kinds of dispersed (particulate) phases (for example dust particles, metal chips, wooden waste, liquid droplets) and different gas conditions (pressure, temperature) the lay out and computation of a cyclone is still a complex task. Suvis has specialised in the development and lay out of cyclone separators and can offer professional solutions and consulting in the area of gas cyclones. Many years of experience gained through numerous cyclone development projects results in optimal solutions for our customers. A cyclone separator applies centrifugal forces and represents an effective apparatus for separating gas, liquid or solid particles from a continuous phase in chemical, process or environmental engineering.

Request for a quote

SCHWEIZER GMBH & CO. KG

Germany

Universal tank caps and threaded flanges.

Request for a quote

SUVIS GMBH

Germany

The Suvis GmbH also deals with the application of modern numerical methods for the lay out and optimisation of various separator types like cyclones. A typical application of these computation methods is the computer aided investigation of particle separation from gases in cyclones. The prediction of the separation efficiency allows the reliable optimisation of conventional cyclones and the development of completely novel high efficiency cyclones. With that, very often expensive filter units, wet cleaner, or costly electro filters can be replaced or completed. When applying numerical methods (CFD simulations) to cyclones one encounters the problem of strong curvature of the stream lines because of the resulting strong swirl flow and the abrupt change of flow direction towards the outlet tube. This means that the assumption of isotropic turbulence is not useful anymore.

Request for a quoteRequest for quotes

Create one request and get multiple quotes form verified suppliers.

- Only relevant suppliers

- Data privacy compliant

- 100% free