VEN DRY

OIR

Description

With the VEN DRY OIR dryer, the surface quality of lacquered workpieces can be considerably improved while simultaneously reducing the drying times. Premature closure of the surface is effectively prevented by evaporating the surfaces in conjunction with targeted heat application into the paint layer interior. The paint uniformly and quickly dries from inside out. The OIR flat evaporation tunnel in modular design with belt conveyor optimally meets all requirements. The standard equipment comprises three IR radiator modules, each equipped with two radiators and easily accessible through lateral inspection flaps.

Similar products from VENJAKOB MASCHINENBAU GMBH & CO KG

VENJAKOB MASCHINENBAU GMBH & CO KG

Germany

high-performance curing of 3d workpieces Venjakob has introduced innovative LED technology to 3D curing. The lower thermal stress of the workpieces and optimized energy consumption are compelling advantages. The air in the factory is not contaminated with ozone – as is the case with conventional UV technology – and the longer lifetime of the LED lamps improves the energy balance. System benefits BLUE COMPETENCE

Request for a quote

VENJAKOB MASCHINENBAU GMBH & CO KG

Germany

The demands on production processes often change very quickly. VEN DRY VARIO TIME makes it possible to react quickly. The batch is detected by light barriers at the infeed and the dwell time in the dryer is controlled accordingly by the state-of-the-art control system. The special handling technology with sophisticated Venjakob control system exceeds your expectations for a powerful and flexible dryer concept. Loading locations: 38 Operating width: 1,300 mm Pallet length: 5,600 mm Useful length: 5,500 mm Loading per palletmaximum: 100 kg Item heightmaximum: 60 mm

Request for a quote

VENJAKOB MASCHINENBAU GMBH & CO KG

Germany

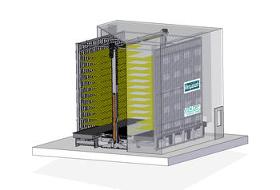

The drying method is based on a hot air-circulating air system, divided into different zones. A well thought-through ventilation system ensures uniform and effective ventilation in all parts of the dryer. The flexible system can be used to dry almost all types of lacquers/paints except for hardening lacquers/paints such as UV and EBC lacquers. The high-performance vertical dryer consists of a defined number of belt pallets. Following lacquer application, the parts move into the dryer and stop on a pallet which subsequently raises. The subsequent pallet is then ready for the infeed of the next workpieces. The dryer is manufactured in modular construction and adapted to the requirements of the customer. Batch length: maximum 6,200 mm Batch width: maximum 1,300 mm Batch height: maximum 50 to 90 mm

Request for a quote

VENJAKOB MASCHINENBAU GMBH & CO KG

Germany

UV curing paint systems are hardened within seconds by intensive UV radiation. These systems permit short production processes requiring little space. The number of required radiators depends on the throughfeed speed, the type of paint, the quantities applied and the workpiece geometry. Performance optimised UV lamps are used in the VEN DRY UV dryer. These feature emission spectra perfectly matched to the individual paint/lacquer. Mature transformer technology in combination with high-performance UV lamps ensure safe and reliable operation. The new generation of dryers with "SURROUND-UV" technology offers the following advantages:

Request for a quote