- europages

- >

- Pumps

- >

- VILLINA LLC

- >

- products

VILLINA LLC - Manufacturer of pumps for the oil, gas and chemical industries

Russia

Manufacturer/ Producer

VILLINA LLC

Russia

Centrifugal pumps have well-known advantages such as uniform pumping without surges, the ability to create high pressures at low pump rate in multi-stage designs, long service life and others. Advantages: the fluid can be taken in at a point lower than the axis of the inlet suction pipe without using a pre-installed vacuum pump. - Purpose: transit of corrosive, toxic, explosive and flammable fluids at insufficient suction pressure; - Pump rate ranges: 0.8 to 450 m3/h; - Head ranges: 3 to 132 m; - Self-priming height (depth): up to 6 metres; - Seal type: magnetic coupling according to API 685 or tandem mechanical seal according to API 682; - Climatic version: for moderate and for moderate and cold climate; - Temperature of the pumped fluid: for GNGC-S, GNGC-S-M up to plus 350°С, for NCG-S up to plus 450°С; - Shaft speed: 1,450 or 2,900 rpm; - Structural design: ОН-2 single-stage back pull-out pump according to API 610 or a single block.

Request for a quote

VILLINA LLC

Russia

Centrifugal pumps have well-known advantages such as uniform pumping without surges, the ability to create high pressures at low pump rate in multi-stage designs, long service life and others. However, operation of centrifugal pumps requires building positive pressure (pressure boosting) upstream of the inlet suction pipe for the following reasons: to fill the pump body with the pumped fluid in order to avoid a "dry start" to prevent cavitation during pump operation. Classic methods for creating pressure boosting before centrifugal pumps can be: installation of a tank from which the fluid is pumped, several meters above the axis of the pump shaft and placing the pump in the draw-off sump; inclusion of an additional vacuum pump into the process, which is capable of building the desired pressure boosting of several metres. HOW IS THE PROBLEM OF CREATING A PRESSURE BOOSTING IN MODERN SELF-PRIMING CENTRIFUGAL PUMPS SOLVED? Villina company offers you Villina self-priming GNGC series

Request for a quote

VILLINA LLC

Russia

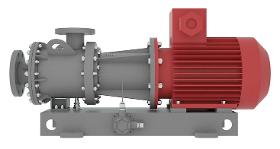

Modern petrochemical and gas industries typically use horizontal centrifugal canned pump units with magnetic couplings similar to Villina-GNGC type pumps. They are designed for transiting neutral, corrosive, toxic, as well as explosive and flammable liquids in stationary conditions, the vapors of which can form explosive mixtures with air. Magnetic coupling pumps combine complete tightness, smooth operation, long service life and high maintainability. A sub-type of horizontal pumping units are high-temperature pumps Temperature of the pumped fluid: -50°C to +420°C; viscosity up to 26 cSt; density 2,000 kg/m3 maximum; mass concentration of solid non-abrasive inclusions up to 0.2%; size 0.2 mm maximum Permanent magnets (SmCo) with an operating temperature of up to 450°C are used for operation in these temperature conditions. The pump, a part of the pumping unit, is a single-stage or multi-stage horizontal centrifugal section-type

Request for a quote

VILLINA LLC

Russia

Villina-VS1-M type pumps are designed for use in oil and gas and chemical industries for transit of explosive and highly flammable liquids as well as corrosive media and natural gas liquids. A distinctive feature of these pumps is the ability to transit contaminated liquids with particle size of 3 to 12 mm (depending on the pump rate). MAIN SPECIFICATIONS - Pump rate ranges: 2 to 108 m3/h; - Head: 11 to 178.5 m; - Temperature of the pumped fluid: -50°С to +440°С.

Request for a quote

VILLINA LLC

Russia

ADVANTAGES - GNVC-P vertical semi-submersible pumps are developed and manufactured according to individual parameters of the Customer and in compliance with normative documents. - Time of manufacture: 90 days. - Warranty period: 24 months. - Chemical pumps are capable of pumping liquids with viscosity up to 35 cSt, and density up to 2,000 kg/m3. PERFORMANCE SPECIFICATIONS - Purpose: transit of corrosive, toxic, explosive and flammable fluids; - Pump rate ranges: 1 to 55 m3/h; - Head ranges: 5 to 250 m; - Seal type: a magnetic coupling according to API 685 with a sealing sleeve made of Hastelloy alloy (standard version) ensures 100% tightness; - Temperature of the pumped fluid: up to plus 250°С; - Shaft speed: 2,900 rpm; - Structural design: type VS4 according to API 610, vertical type, fixed installation on the container neck on the base plate; - Submergence: 1 to 6 metres, with a length increment of 10 cm for the choice of a specific immersed part length of the pump.

Request for a quote

VILLINA LLC

Russia

One of the priority areas in the production of Villina pumping equipment was initially the development of a specialized line of pumps designed for pumping harsh chemical fluids. At present, we are ready to offer you Villina high-end lined centrifugal canned pumps having design life of 20 years for pumping mineral and organic acids, alkalis, salts, oxides and anhydrides, including chlorides, as well as alcohols, esters, aromatic hydrocarbons, ketones, aldehydes and other media which contain various concentrations of mordant substances. Modern technology makes rapid progress, and in place of pumps used earlier for transit of corrosive fluids made of chemically resistant yet expensive steels such as KhN65МV, N70MFV, 06KhN28MDT, lined pumps are widely used now. In accordance with para. 51 of the Safety Rules of chemically hazardous production facilities, corrosion-resistant non-metallic coatings (polyethylene, fluoroplastic) can be used to protect equipment and pipelines

Request for a quote

VILLINA LLC

Russia

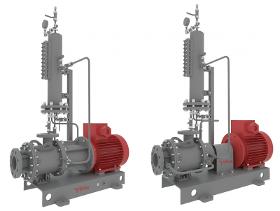

Our products include Villina-GNGC-2T type centrifugal horizontal pumps with tandem mechanical seals type according to your parameters. These are used for transit in stationary conditions of neutral, corrosive, toxic, as well as explosive and fire hazardous liquids, the vapors of which can form explosive mixtures with air. The units are mainly used by petrochemical industry companies. Parameters of operating fluids (liquids): temperature from -50oС to +400oС viscosity up to 160 cSt density 2,000 kg/m3 max, with a high concentration of particles particle size over 0.2 mm, but not exceeding free passage of the impeller (3 to 12 mm depending on the pump rate) For such conditions, mechanical seals (operating temperature up to 425°C) of well-known companies are used, such as: OOO NPC ANOD, JSC TREM ENGINEERING, UNICHIMTEK Group of Companies and others DESIGN FEATURES The unit consists of a pump, a base plate, an electric motor, a casing and a support system.

Request for a quote

VILLINA LLC

Russia

The Villina GNGC series horizontal canned centrifugal pumps with magnetic couplings are widely used in oil and gas companies of Russia and its neighbouring countries for transit of explosive and flammable, toxic and corrosive fluids. The horizontal arrangement allows the use of a GNGC as a replacement for technically obsolete and physically worn pumps without significantly changing the geometry of the location and pump lines group assembly systems. 100% tightness, structural design in accordance with API 610, 685 (ISO 13709) standards and explosion-proof design of GNGC pumps are approved by design institutes and Rostekhnadzor for use in projects for modernization, reconstruction or construction of new facilities. GNGC horizontal pumps with magnetic couplings provide for axial position of the suction pipe and radial position of the delivery pipe. The motor and pump body are mounted on supports (OH 2 according to API 610), the drive shaft of the motor

Request for a quote

VILLINA LLC

Russia

Horizontal canned pumps with welded bodies (Villina-GNGC) are designed for transit in stationary conditions of neutral, corrosive, toxic, as well as explosive and fire hazardous liquids, the vapors of which can form explosive mixtures with air. These pumps are used in petrochemical, petroleum refining and other industries. single-stage or multi-stage version of the unit design (increased discharge pressure, in contrast to back pull-out pumps); high efficiency of the impellers; a possibility to pump contaminated liquids with 100% tightness (for pumping units with combined seals); Temperature of the pumped fluid: up to +420°С.

Request for a quote

VILLINA LLC

Russia

Villina-VS1-М, Villina-GNVC-K and Villina-GNGC-K type centrifugal canned pump units with combined seals are widely used in modern gas industries, petrochemical and petroleum refining industries. They are designed for transiting neutral, corrosive, toxic, as well as explosive and flammable liquids in stationary conditions, the vapors of which can form explosive mixtures with air. For such conditions, mechanical seals with operating temperatures up to 425°C of well-known companies are used, such as: OOO NPC ANOD, JSC TREM ENGINEERING, UNICHIMTEK Group of Companies and others, as well as permanent magnets (SmCo) with operating temperatures up to 450°C. Villina type units are made in three versions as regards the spatial location of the pump rotor: vertical ground-level (Villina-VS1-M) - the pumped liquid is supplied to the pump part of the unit through a suction pipe located radially to the pump rotor. The unit consists of a pump part, a device

Request for a quoteeuropages also recommends

A selection of companies related to the activity:

A selection of products that might interest you

POMPES JAPY

France

Body, flange, screw and shaft: stainless steel Couplings: stainless steel (nylon as an option with code -A) Membrane and valves: made of a hydrocarbon-resistant elastomer (Neoprene as an option with code -A) Lever: zinc-plated steel with a rubber handle, 1 metre in length

Request for a quote

PARSMEGA MAKINA

Turkey

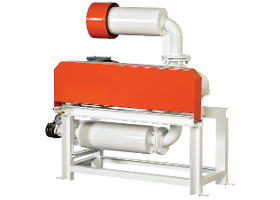

Blower pumps are used in mill systems to meet the air required by the supersonic filter and to transport products vertically and horizontally.

Request for a quote

FOCQUET

Belgium

"We have different solutions at the industrial pump level. We offer two solutions in our product range: thermal oil transfer or water transfer. In the pumps offered by Focquet, we have mainly bare shaft pumps mounted on base, monobloc pumps and in-line pumps. The pump department is specialized in the overhaul of pumps of all brands and the assembly of pump units with a very short delivery time. We have a great deal of expertise and know-how in industrial pumps and a large stock of spare parts in order to respond to our customers' emergencies as well as possible."

Request for a quote

HUGE PUMP

Turkey

Helical gear pumps are produced from stainless steel and cated materials. Gear pumps which are perfect for fluid with diffirent characteristics with high and low viscosity are used in food, beverage and medicine industries varying from fuel transmission to different chemicals together with its hygienic series.

Request for a quoteRequest for quotes

Create one request and get multiple quotes form verified suppliers.

- Only relevant suppliers

- Data privacy compliant

- 100% free