- europages

- >

- Binding - machinery and equipment

- >

- AUTOMAZIONI INDUSTRIALI CAPITANIO SRL

- >

- WIRE TIES MACHINES

WIRE TIES MACHINES

The ATS Mechatronics machine creates the requested wire ties.

Description

GENERAL OPERATION The machine is built-up of a rotating plate and a knot device that allow to create the requested wire ties. When the cycle is running, the pinch roll insert the wire in the machine and the rotating plate starts to rotate creating the wire ties. The crossed ends of the wire are held together and twisted by rotation of the gripper. AUTOMATIC CYCLE When the operator press the “start” button, the automatic cycle command is sent to the machine. This signal allow to insert the wire into the rotating plate following the sequence below: - Realignment and lifting of the twister. - Realignment of the wire step cylinder. - Closing of the pinch roll. - Moving forward of the puller. - Insertion of the wire by means of forward rotation of the pinch roll. When the twister is in high position, the puller is moved forward, in order to pull out the wire ties. With a time delay, the machine starts a new tying cycle (according to the number of the ties set in the operator’s panel).

- Binding - machinery and equipment

- Metallurgy and iron and steel industry - machinery and installations

- Tying machines

- Wire bending

Similar products

HERBERHOLZ GMBH

Germany

Applications: Environmental Technology / Mechanical and Plant Engineering / Renewable Energy Technology One-piece body, centric disc Also available as multi-blade version Operating temperatures up to 900°C, depending on material selection Flanged body according to DIN 24193 or customer specification Face-to-face length according to manufacturer’s standard or individual customer specifications Mounting flange for actuators according to DIN EN ISO 5211 Inspection according to DIN EN 12266

Request for a quote

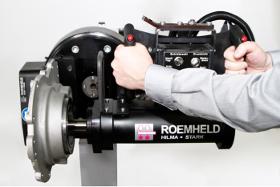

RÖMHELD GMBH FRIEDRICHSHÜTTE

Germany

Hydraulic pull-in device for mounting bearings max. pulling force 100 kN, stroke up to 200 mm, horizontal design Application The bearing press is suitable for the simple mounting of bearings, plain bearings or sleeves/bushings by hydraulically pulling them into the bearing seat. Main areas of application - Industrial assembly workstations - Mounting bearings in housings - Maintenance work - Bearing assembly on large/heavy components Description The bearing press is designed for the hydraulic insertion of bearings into housing components and is available in a horizontal design. Guided on a knuckle boom crane with a balancer (not included in the delivery), the bearing press can be used ergonomically anywhere and can also be mounted on a trolley. The pullin cylinder can be used either from the right or left by converting the hydraulic cylinder. The device is operated by means of a twohand control.

Request for a quote

XIAN HUAN-TAI TECHNOLOGY & DEVELOPMENT CO., LTD.

China

Dross pan with drain holes for aluminum recycling industry. Skim Pan Dross Pan with drain holes for aluminum recycling industry. Made of a patented material which is developed by our own, our Skim pans and sow molds have a very durable quality. We innovatively re-design our skim pans and sow molds to make them have a very fast cooling speed, which results in a remarkable reduction of oxidation. In addition to our patented material, we can provide the options for materials to fit in different applications of customers. We produced many skim pans and sow molds of different sizes, they cover many applications. Meanwhile, we are always willing to offer designs to customers to meet their own specific needs. Huan-Tai offer ingot molds with many sizes of standard, low-profile and high-profile, and with or without fork pockets as in the table below. Our molds are cast from a proprietary material, the material is developed by our own to provide a very good durability.

Request for a quote

IMM MASCHINENBAU GMBH

Germany

Heavy duty belt sanding and polishing jack for industrial applications. Compact double ended design. Floor standing pedestal. Rapid belt tensioning and tracking. Also for alumimun polishing.

Request for a quoteRequest for quotes

Create one request and get multiple quotes form verified suppliers.

- Only relevant suppliers

- Data privacy compliant

- 100% free