- europages

- >

- Stoppers and caps- plastic

- >

- SEAL CAP LINERS

- >

- cap seal liners

cap seal liners

cap seal liners , induction heat seal, foam liners , vented liners

Description

We are experts in seal liners; do not hesitate to contact us whenever you have a new project or Having sealing needs or problem with your packaging. 20 years of experience in packaging and sealing materials allowing us to support you in the best way there is. We will analyze your cap & closure seal liner and your specific packaging needs in terms of shelf life, raw material, end user product including everyone expectation.If needed we will test your application & recommend our best seal liner solution and let you have samples for your own inspection.(foam ,epe, eps ,induction heat seal,vent or special seal) We are responding quickly and we reliable and professional.

- Stoppers and caps, plastic

- cap liners

- induction heat seal liners

- foam cap liners

Similar products

MICRON AMERICA

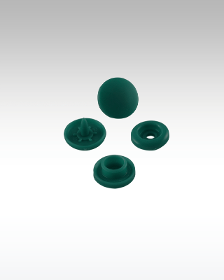

Turkey

Micron plastic snaps made from the best plastic material we can source and is easy to attach using our dies and machines. These plastic snaps are used by our clients for products like rain coats, textiles, umberella, toys, baby clothing and much much more.

Request for a quote

BÜRKLE GMBH

Germany

Screw-on closure with tamper-evident ring for compact jerrycan. Screw-on cover made of PP, seal made of PE, thread DIN50. The closure offers protection against tampering and a guaratee that the container has not been opened before, since the snap ring is visibly broken the first time the container is opened.

Request for a quote

MSY INVEST BV

Belgium

Magnetic snoring stopper (2 pcs.) So that you can finally sleep peacefully and relax again! During sleep, the muscles sag in the posterior throat area, which makes it difficult for breathing air to pass and a slight Vibration causes - the unloved snoring. Due to the easy-to-use, magnetic snoring stopper prevents this! The clip exerts a gentle pressure on the Nasal septum and causes a slight expansion of the nasal passages so that you be able to breathe freely. For undisturbed, restful nights! 2 Pieces Magnetic Snore Stopper This set includes 2 magnetic snore stoppers and a storage box Settled in the nostrils it clear air passage and thus stop snores Delivery incl. storage box. Item dimensions: 1.9 x 1.4 x 0.4 cm Diameter of the magnetic spheres 0.4 cm each Storage box 3.5 x 3.5 x 2 cm. Material: TPR, magnets. Includes 2300 Gauss magnets per piece.

Request for a quoteRequest for quotes

Create one request and get multiple quotes form verified suppliers.

- Only relevant suppliers

- Data privacy compliant

- 100% free