- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- lubrication equipment and machinery

Results for

Lubrication equipment and machinery - Import export

DAMS MACHINE

Turkey

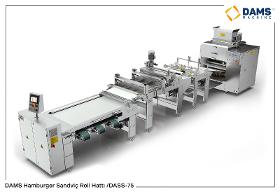

The settings are made easily from the PLC-controlled touch screen. Mechanical settings are simple to use and easy to learn. Information on usage can be stored in memory and used continuously. Daily cleaning is easy. It is easy to disassemble, install and replace belts and running parts. The speeds of all belts can be adjusted to the desired level. Electrical and electronic faults that may occur are displayed on the PLC screen with pic and text.

Request for a quote

DAMS MACHINE

Turkey

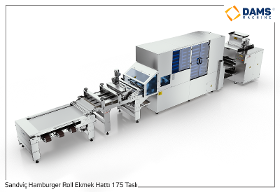

Roll, Sandwich Hamburger and similar sized products and Francala Bread are individually wrapped. Our machine has a servo motor system. Thanks to the touch screen and PLC on the machine, product package length, photocell adjustment and machine speed can be adjusted as desired. There is a sensor control system that prevents jamming of the product. If the product location is not correct, it stops the machine. All surfaces and covers that are in contact with the product in the machine are made of 304 quality chrome-nickel metal. Rotating jaw system. It packs 115 products per minute (roll, sandwich hamburger and similar products), and 83 products per minute in Francala Bread. It easy to use. Optionally, it is produced so that a coding device can be mounted on the machine. Cellophane bobbin is easy to disassemble and install, the place where it is mounted is an air system and PLC controlled shaft.

Request for a quote

DAMS MACHINE

Turkey

Roll Bread Packaging is done one by one. Thanks to the touch screen and PLC, there is easy access and intervention to the package size of the product, intelligent eye photocell adjustment and machine speed. Our Machine has intelligent motor system servo motor automation. There is a product control sensor that prevents the Roll Blower or other products from being jammed during packaging. During packing, the packaging does not crush the bread. If the location of the plant is not suitable, the intelligent eye sensor stops the machine. The machine is also made of 304 quality stainless chrome-nickel metal suitable for all surfaces that contact with the product and environmental protection covers. Our machine has been produced on the product in accordance with the operation of the device which outputs information such as date of production-serial number expiration date. This machine is optional. Emergency Stop has been put in place to provide user and machine security.

Request for a quote

DAMS MACHINE

Turkey

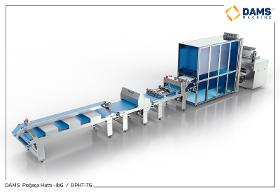

The settings are made easily from the PLC-controlled touch screen. Mechanical settings are simple to use and easy to learn. Information on usage can be stored in memory and used continuously. Daily cleaning is easy. It is easy to disassemble, install and replace belts and running parts. The speeds of all belts can be adjusted to the desired level. Electrical and electronic faults that may occur are displayed on the PLC screen with pic and text.

Request for a quote

DAMS MACHINE

Turkey

The settings are made easily from the PLC-controlled touch screen. Mechanical settings are simple to use and easy to learn. Information on usage can be stored in memory and used continuously. Daily cleaning is easy. It is easy to disassemble, install and replace belts and running parts. The speeds of all belts can be adjusted to the desired level. Electrical and electronic faults that may occur are displayed on the PLC screen with pic and text.

Request for a quote

DAMS MACHINE

Turkey

The settings are made easily from the PLC-controlled touch screen. Mechanical settings are simple to use and easy to learn. Information on usage can be stored in memory and used continuously. Daily cleaning is easy. It is easy to disassemble, install and replace belts and running parts. The speeds of all belts can be adjusted to the desired level. Electrical and electronic faults that may occur are displayed on the PLC screen with pic and text.

Request for a quote

DAMS MACHINE

Turkey

The settings are made easily from the PLC-controlled touch screen. Mechanical settings are simple to use and easy to learn. Information on usage can be stored in memory and used continuously. Daily cleaning is easy. It is easy to disassemble, install and replace belts and running parts. The speeds of all belts can be adjusted to the desired level. Electrical and electronic faults that may occur are displayed on the PLC screen with pic and text. In case of malfunction, remote access can be performed with PLC program.

Request for a quote

DAMS MACHINE

Turkey

The settings are made easily from the PLC-controlled touch screen. Mechanical settings are simple to use and easy to learn. Information on usage can be stored in memory and used continuously. Daily cleaning is easy. It is easy to disassemble, install and replace belts and running parts. The speeds of all belts can be adjusted to the desired level. Electrical and electronic faults that may occur are displayed on the PLC screen with pic and text.

Request for a quote

DAMS MACHINE

Turkey

The settings are made easily from the PLC-controlled touch screen. Mechanical settings are simple to use and easy to learn. Information on usage can be stored in memory and used continuously. Daily cleaning is easy. It is easy to disassemble, install and replace belts and running parts. The speeds of all belts can be adjusted to the desired level. Electrical and electronic faults that may occur are displayed on the PLC screen with pic and text.

Request for a quote

DAMS MACHINE

Turkey

The settings are made easily from the PLC-controlled touch screen. Mechanical settings are simple to use and easy to learn. Information on usage can be stored in memory and used continuously. Daily cleaning is easy. It is easy to disassemble, install and replace belts and running parts. The speeds of all belts can be adjusted to the desired level. Electrical and electronic faults that may occur are displayed on the PLC screen with pic and text. In case of malfunction, remote access can be performed with PLC program (Optional) CUTTING SECTION Machine body is 304 crom. The contact surfaces of the dough are 304 crom and crom coating.

Request for a quote

DAMS MACHINE

Turkey

Dough balls which are prepared according to the diameter of the desired product are released one by one into the hopper of the machine. The dough is crushed between two homogeneously heated plates with the hot pressing techniques. When the plates are spacing the rolled dough slides out of the machine. When the plates are spaced, the new dough roll falls between the plates from the hopper. Temperature of each plate; It is controlled by measuring separately. Product thickness can be adjusted manually.

Request for a quote

DAMS MACHINE

Turkey

DIVIDER & ROUNDER Up to 11000 pcs/hour capacity Weight range 40-140 grams (±2 gr) 6 pieces 50mm diameter pistons Changable outer drum for different weights 6 row outlet belts Automatic oil lubrication Variable speed controls for main drive and rounding unit Flour duster Dough bunker capacity is 210 kg Total power 5 kW 7 inc HMI Touch Panel PLC control INTERMEDIATE PROOFER Proofing time 10 minutes (for10.000pcs/hour) 6 pocket stainless steel dough carrier tray 278 pieces active tray 1668 active pockets Removable and washable UHMWPE mesh pockets 2″roller chain for tray transport Main frame is stainless steel tube. Total power 1.5 kW.

Request for a quote

DAMS MACHINE

Turkey

DIVIDER & ROUNDER Upto 11000 pcs/hour capacity Weigh trange 40-140 grams (±2 gr) 6 pieces 50mm diameter pistons Changable outer drum for different weights 6 row outlet belts Automatic oil lubrication Variable speed controls for main drive and rounding unit Flour duster Dough bunker capacity is 210 kg Total power 5 kW 7 inc HMI TouchPanel , PLC control INTERMEDIATE PROOFER Proofing time 10 minutes (for 6000pcs/hour) 6 pockets stainless steel dough carrier tray 139 pieces active tray 834 active pockets Removable and washable UHMWPE mesh pockets 2″ roller chainfortray transport Main frame is stainless steel tube. Total power 1.5 kW Easy Access for maintenance Safety switches on doors.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

DAMS MACHINE

Turkey

The settings are made easily from the PLC-controlled touch screen. Mechanical settings are simple to use and easy to learn. Information on usage can be stored in memory and used continuously. Daily cleaning is easy. It is easy to disassemble, install and replace belts and running parts. The speeds of all belts can be adjusted to the desired level. Electrical and electronic faults that may occur are displayed on the PLC screen with pic and text. In case of malfunction, remote access can be performed with PLC program (Optional)

Request for a quote

SHINYOUNG MECHANICS CO.,LTD

South Korea

The rice cake popping machine of Shinyoung Mechanics is a device that can make grain snacks, chips, cakes, etc., out of 100% natural cereals. Gluten free products using rice or corn can be made, and breakfast cereal or children’s snacks can also be made with wheat, sorghum, barley, brown rice, buckwheat, etc. Also, using various food pellets, potato chips, beans, or sweet potatoes can be made into healthy snacks without going through the frying process. As you can see in the photo, you can make grain cake with rice or wheat, and you can produce cake or chip type product using various shapes and various raw materials. Users Large confectionery producer Medium and small sweets producer Snack manufacturer Rice cake maker Grain distributor or processor Large food manufacturer Medium and small food manufacturer Small local shops using local specialties or local mascot shapes For more information, please contact us !! Thank you Shinyoung Mechanics

Request for a quote

SHINYOUNG MECHANICS CO.,LTD

South Korea

RICE CAKE MACHINE (SYP Model) As this Shinyoung Mechanics is a company which specializes in production of the Rice Cake Popping Machine, we are keeping the No. 1 domestic sales through the 2007 SYP series and being recognized its excellence selling the product of over 1,500 units to 50 countries worldwide. Since our SYP Rice Cake Popping Machine is that design is compact and convenience is superior on the use and time, thickness, shape etc are possible to control easily, it is in wide use from store up to factory. As the 100% Grain Snack is that nutritious ingredient is excellent and consumer recognition is good, it is easy to commercialize. As of now a variety of products such as general snack (chocolate-coated, flavor-seasoned), cereal for meal substitution or diet, children snack etc are being developed and sold. Thank you

Request for a quote

USTUNELLER MAKINA

Turkey

With the help of 2 or 4 polyamide rollers, it forms the dough in the form of pita bread with the help of pillows in the desired length and thickness. The roller setting can be changed steplessly between 0-30 mm. There is a spring scraping mechanism on the rollers to prevent the dough from sticking. Thanks to the adjustable roller group, the dough can be shaped to a length of 420 mm. The folding chain and its parts are made of stainless steel. It has a dough shaping capacity of 2500 per hour and the ability to process 100-1200 gr dough.

Request for a quote

USTUNELLER MAKINA

Turkey

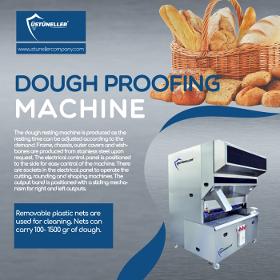

The dough resting machine is produced as the resting time can be adjusted according to the demand. Frame, chassis, outer covers and wishbones are produced from stainless steel upon request. Removable plastic nets are used for cleaning. The nets can carry 100- 1500 gr of dough. The electrical control panel is positioned to the side for easy control of the machine. There are sockets in the electrical panel to operate the cutting, rounding and shaping machines. The output band is positioned with a sliding mechanism for right and left outputs.

Request for a quote

USTUNELLER MAKINA

Turkey

CONICAL ROUNDING MACHINE. The conical rounding machine shapes the dough with a conical made of aluminum and aluminum arms circulating in a spiral around it. The dough coming from the cutting-weighing machine falls into the aluminum inlet chute. Thanks to the rolling drum and guiding grooves, it takes a round shape and reaches the resting machine. Meanwhile, the dough is prevented from sticking to the discharge chute with the flour sifting device. Thanks to the optional ventilation system, air is blown into the grooves, preventing the dough from sticking to the drum. All aluminum parts can optionally be coated with Teflon. 7 types of machines are produced that shape 200-1500 gr dough with adjustable arms, varying between standard 50-1500 gr.

Request for a quote

TURKIYE MACHINES BAKERY MACHINES

Turkey

These ovens are ideal for small bakeries, however can also work very well in larger bakeries as a sec-ond oven for baking of smaller products such as baklava, pizza, pie, pastry, cake, sponge and all other yeast having dough types. Control panel is produced as touch screen or manual type. Up to 5 decks can be used on each and there is equipment which supply moist environment for fer-mented products at underside of the oven. Also the stainless steel table is available. The number of trays for each deck could be seen on technical specifications page. Each deck can be controlled individually between 0-300 C and heat of ceiling and base are managed as separately. It is only produced as an electrical. Holding heat of stone bases is in maximum level.Products can be observed clearly through glass doors and powerful enlightening. Option Manual and touchscreen control panel / Fermentation or stainless table for bottom of oven.

Request for a quote

TURKIYE MACHINES BAKERY MACHINES

Turkey

Automatic Divider Machine Specifications Weight adjustment by touchscreen panel • The main body is made completely of stainless steel. • Dough counting screen • Electronic speed control unit • Dough twicing system on the conveyor band. • Drum surface chrome plated. • Piston slot is made of stainless steel. • Vacuum piston is made of anti-oxidation materia Manuel Dividing Machine Specifications Weight adjustment by hand wheel • The main body is made completely stainless steel • Drum surface chrome plated • Piston slot is made of stainless steel. • Vacuum piston is made of anti-oxidation material. • 24 V Control board • Closed circuit lubrication system. • Piston movies to discharge position automatically when the machine shut-off • 70 kg. hopper capacity • Stainless steel lids. • Belt/pulley power transmission system Option Single or double piston 50-200, 100-600 and 250-1000 gr dividing range Manual and touchscreen control panel Teflon coated hopper Big sized hopper (140 lt dough capac

Request for a quote

TURKIYE MACHINES BAKERY MACHINES

Turkey

Removable spiral mixer with removable bowl designed for industrial plants and heavy duty applications. Excellent kneading and practical usage merged by two speed powerful motor, separated kneading process by two different timers and high power transmission to removable bowl. Moreover long term usage also has been guaranteed by strong chassis. Head of mixer lifts up automatically at the end of kneading process and allows to remove the bowl by user. The bowl is fasten to the mixers body with a locking system. By the way kneading standardization is always assured. The other specifications of removable bowl mixer are as follow: stainless steel bowl, knife and spiral hook, automatic and manual control, silence in mechanical system and power transfer, mechanical system and security system according to CE standards. Additional bowl and lifting tilting systems are available. Option Touch Screen / Temperature Probe / Water Dosing Systeme..

Request for a quote

TURKIYE MACHINES BAKERY MACHINES

Turkey

Convection ovens are particulary suitable for baking small volume cake, pastry, sandwich and bread production at patisseries, restaurants, hotels, and bakeries. Hot air circulation is provided by inner fans (one fan for 4 or 5 trays oven, and double fans for 8 trays oven), and spread all over the baking area to provide a homogenous environment. The fermentation unit placed bottom of the oven provides the humidity and temperature needed for fermentation process. Convection oven models for 5 trays is produced only with electric heating system. For the other model 8 trays capacity both electric and gas heating system is possible Control panel can be produced with manual buttons (standard) or touchscreen panel (option).

Request for a quote

TURKIYE MACHINES BAKERY MACHINES

Turkey

1. Double frequency converter control, the bag length can be set and cut, no need to adjust the air, one step in place, saving time and film. 2. Man-machine interface, parameter setting is convenient and quick. 3. Fault self-diagnosis function, the fault display is clear at a glance. 4. High-sensitivity photoelectric eye color tracking, digital input sealing and cutting position, making the sealing and cutting position more accurate. 5. Temperature independent PID control, better suited to a variety of packaging materials. 6. Reciprocating end seal mechanism, the seal is more firm, and the seal cutter has no loss. 7. End sealing angling device, the bag shape is more beautiful, and the product grade is improved. 8. Positioning stop function, no sticking knife, no waste film. 9. The transmission system is simple, the work is more reliable, and the maintenance is more convenient. 10. All control is realized by software, which is convenient for function adjustment and technical upgrade.

Request for a quote

TURKIYE MACHINES BAKERY MACHINES

Turkey

This machine is designed with a rotating cone and adjustable spiral shaped corrosion resistant tracks around it. The dough becomes perfectly rounded while moving from bottom to top in the tracks which are adjustable. The machine is also equipped with a newly designed mechanical flour duster which does not make any noise while working. The standard rounding track is 4.5 meters. The weight range is from 100 gr. To 600 gr. Electric power 0.55 kw 220/380 V AC.50 Hz. It is also possible to produce 50 gr. To 200 gr. working capacity rounder machine. rounding track is 4.5 meters. The weight range is from 100 gr. To 600 gr. Electric power 0.55 kw 220/380 V AC.50 Hz. It is also possible to produce 50 gr. To 200 gr. working capacity rounder machine. Option Hot and cold air blowing system / Teflon coated channels or conic body / Electronic speed control

Request for a quoteResults for

Lubrication equipment and machinery - Import exportNumber of results

37 ProductsCompany type