- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- dairies - machinery and equipment

Results for

Dairies - machinery and equipment - Import export

ASTRA LT AB

Lithuania

Milk storage tanks Asepting tanks Yogurt production tanks Milk pasteurizes Equipment for curd cheese production Milk floats Milk accounting systems Technological process automation

Request for a quote

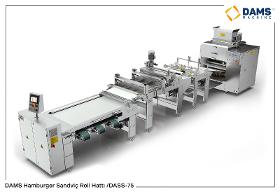

DAMS MACHINE

Turkey

Roll, Sandwich Hamburger and similar sized products and Francala Bread are individually wrapped. Our machine has a servo motor system. Thanks to the touch screen and PLC on the machine, product package length, photocell adjustment and machine speed can be adjusted as desired. There is a sensor control system that prevents jamming of the product. If the product location is not correct, it stops the machine. All surfaces and covers that are in contact with the product in the machine are made of 304 quality chrome-nickel metal. Rotating jaw system. It packs 115 products per minute (roll, sandwich hamburger and similar products), and 83 products per minute in Francala Bread. It easy to use. Optionally, it is produced so that a coding device can be mounted on the machine. Cellophane bobbin is easy to disassemble and install, the place where it is mounted is an air system and PLC controlled shaft.

Request for a quote

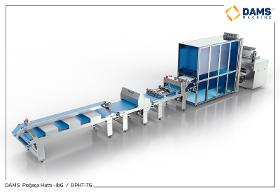

DAMS MACHINE

Turkey

Roll Bread Packaging is done one by one. Thanks to the touch screen and PLC, there is easy access and intervention to the package size of the product, intelligent eye photocell adjustment and machine speed. Our Machine has intelligent motor system servo motor automation. There is a product control sensor that prevents the Roll Blower or other products from being jammed during packaging. During packing, the packaging does not crush the bread. If the location of the plant is not suitable, the intelligent eye sensor stops the machine. The machine is also made of 304 quality stainless chrome-nickel metal suitable for all surfaces that contact with the product and environmental protection covers. Our machine has been produced on the product in accordance with the operation of the device which outputs information such as date of production-serial number expiration date. This machine is optional. Emergency Stop has been put in place to provide user and machine security.

Request for a quote

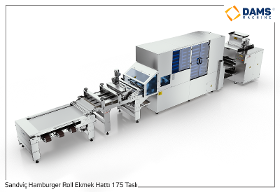

DAMS MACHINE

Turkey

The settings are made easily from the PLC-controlled touch screen. Mechanical settings are simple to use and easy to learn. Information on usage can be stored in memory and used continuously. Daily cleaning is easy. It is easy to disassemble, install and replace belts and running parts. The speeds of all belts can be adjusted to the desired level. Electrical and electronic faults that may occur are displayed on the PLC screen with pic and text.

Request for a quote

DAMS MACHINE

Turkey

The settings are made easily from the PLC-controlled touch screen. Mechanical settings are simple to use and easy to learn. Information on usage can be stored in memory and used continuously. Daily cleaning is easy. It is easy to disassemble, install and replace belts and running parts. The speeds of all belts can be adjusted to the desired level. Electrical and electronic faults that may occur are displayed on the PLC screen with pic and text.

Request for a quote

DAMS MACHINE

Turkey

The settings are made easily from the PLC-controlled touch screen. Mechanical settings are simple to use and easy to learn. Information on usage can be stored in memory and used continuously. Daily cleaning is easy. It is easy to disassemble, install and replace belts and running parts. The speeds of all belts can be adjusted to the desired level. Electrical and electronic faults that may occur are displayed on the PLC screen with pic and text.

Request for a quote

DAMS MACHINE

Turkey

The settings are made easily from the PLC-controlled touch screen. Mechanical settings are simple to use and easy to learn. Information on usage can be stored in memory and used continuously. Daily cleaning is easy. It is easy to disassemble, install and replace belts and running parts. The speeds of all belts can be adjusted to the desired level. Electrical and electronic faults that may occur are displayed on the PLC screen with pic and text.

Request for a quote

DAMS MACHINE

Turkey

The settings are made easily from the PLC-controlled touch screen. Mechanical settings are simple to use and easy to learn. Information on usage can be stored in memory and used continuously. Daily cleaning is easy. It is easy to disassemble, install and replace belts and running parts. The speeds of all belts can be adjusted to the desired level. Electrical and electronic faults that may occur are displayed on the PLC screen with pic and text. In case of malfunction, remote access can be performed with PLC program (Optional)

Request for a quote

DAMS MACHINE

Turkey

The settings are made easily from the PLC-controlled touch screen. Mechanical settings are simple to use and easy to learn. Information on usage can be stored in memory and used continuously. Daily cleaning is easy. It is easy to disassemble, install and replace belts and running parts. The speeds of all belts can be adjusted to the desired level. Electrical and electronic faults that may occur are displayed on the PLC screen with pic and text. In case of malfunction, remote access can be performed with PLC program.

Request for a quote

DAMS MACHINE

Turkey

The settings are made easily from the PLC-controlled touch screen. Mechanical settings are simple to use and easy to learn. Information on usage can be stored in memory and used continuously. Daily cleaning is easy. It is easy to disassemble, install and replace belts and running parts. The speeds of all belts can be adjusted to the desired level. Electrical and electronic faults that may occur are displayed on the PLC screen with pic and text.

Request for a quote

DAMS MACHINE

Turkey

The settings are made easily from the PLC-controlled touch screen. Mechanical settings are simple to use and easy to learn. Information on usage can be stored in memory and used continuously. Daily cleaning is easy. It is easy to disassemble, install and replace belts and running parts. The speeds of all belts can be adjusted to the desired level. Electrical and electronic faults that may occur are displayed on the PLC screen with pic and text.

Request for a quote

DAMS MACHINE

Turkey

The settings are made easily from the PLC-controlled touch screen. Mechanical settings are simple to use and easy to learn. Information on usage can be stored in memory and used continuously. Daily cleaning is easy. It is easy to disassemble, install and replace belts and running parts. The speeds of all belts can be adjusted to the desired level. Electrical and electronic faults that may occur are displayed on the PLC screen with pic and text. In case of malfunction, remote access can be performed with PLC program (Optional) CUTTING SECTION Machine body is 304 crom. The contact surfaces of the dough are 304 crom and crom coating.

Request for a quote

DAMS MACHINE

Turkey

Dough balls which are prepared according to the diameter of the desired product are released one by one into the hopper of the machine. The dough is crushed between two homogeneously heated plates with the hot pressing techniques. When the plates are spacing the rolled dough slides out of the machine. When the plates are spaced, the new dough roll falls between the plates from the hopper. Temperature of each plate; It is controlled by measuring separately. Product thickness can be adjusted manually.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

DAMS MACHINE

Turkey

DIVIDER & ROUNDER Upto 11000 pcs/hour capacity Weigh trange 40-140 grams (±2 gr) 6 pieces 50mm diameter pistons Changable outer drum for different weights 6 row outlet belts Automatic oil lubrication Variable speed controls for main drive and rounding unit Flour duster Dough bunker capacity is 210 kg Total power 5 kW 7 inc HMI TouchPanel , PLC control INTERMEDIATE PROOFER Proofing time 10 minutes (for 6000pcs/hour) 6 pockets stainless steel dough carrier tray 139 pieces active tray 834 active pockets Removable and washable UHMWPE mesh pockets 2″ roller chainfortray transport Main frame is stainless steel tube. Total power 1.5 kW Easy Access for maintenance Safety switches on doors.

Request for a quote

DAMS MACHINE

Turkey

DIVIDER & ROUNDER Upto 7000 pcs/hour capacity Weight range 40-140 grams (±2 gr) 4 pieces 50mm diameter pistons Changable outer drum for different weights 4 rows outlet belts. Automatic oil lubrication Variable speed controlsfor main drive and rounding unit Flour duster Dough bunker capacity is 140 kg Safety switches on doors Total power 5 kW 7 inc HMI Touch Panel PLC control INTERMEDIATE PROOFER Proofing time 10 minutes (for 4000pcs/hour) 4 pockets stainless steel dough carrier tray 146 pieces active tray 584 active pockets Removable and washable UHMWPE mesh pockets 2″ roller chain for tray transport Main frame is stainless steel tube Total power 1.1 kW Easy Access for maintenance Safety switches on doors

Request for a quote

FIS MODULAR SYSTEMS LTD.

Russia

IntelleWaferBall is a wafer balls production line. You can also add variety by changing shapes and sizes (animal figures, filling with boiled condensed milk, creams, etc.). It allows producing products with curd, cheese, salad and pate fillings (salty line).

Request for a quote

FIS MODULAR SYSTEMS LTD.

Russia

IntelleStamp is a modern molding and extruding two-component auger-type complex for molding products from dense masses (toffee, nougat, hematogen, choux pastry for pryaniks, soft nut brittle, chilled dense curd mass) with liquid fillings. It allows you to extrude masses with the addition of particles of 3-5 mm (nuts, raisins, candied fruits, etc.).

Request for a quote

PKO-SURA COMPANY

Russia

Starch molding machine is designed for production of fruit-jelly (including jelly candy), liqueur, fondant sweets and Korovka sweets by starch molding. The machine consists of a movable belt, a molding mechanism and a depositor mechanism. The tray is filled with starch which serves as a forming material. The confectionery mass is fed from the hopper to the dosing unit which performs deposition of sweets/molding the marmalade into molds formed in the starch layer.

Request for a quote

PKO-SURA COMPANY

Russia

Depositors (extruders) are custom-manufactured depending on the needs of the Customer and the parameters of the oven. All projects are coordinated with the Customer and the oven manufacturers. The machine frame is manufactured in the following types: •U-shaped frame; •frame of intermediate section; •frame mounted in the oven tension station. Mechanisms and units of machines are specially designed considering the increased operating temperature and continuous equipment operation throughout the day. (for making various types of cookies, gingerbread, etc.)

Request for a quote

PKO-SURA COMPANY

Russia

Highly automated machines is designed for dosing of dough of various shapes and sizes without or with filling from different confectionery products on a baking pan by extrusion: -shortbread dough (hard or soft); -gingerbread dough; -dough for oatmeal cookies; -biscuit dough; -protein mass (souffle sweetmeat, pastille, marshmallow) The two-hopper mechanism of Сура СД and Сура СДУ depositors ensures the dosing of dough for double-color products or single-color filled products. All Сура С, Сура СД, Сура СДУ machines in standard version are equipped with mechanisms for rotation of draw plates and movement of the conveyor in the vertical plane. Сура СДУ universal depositor can be equipped with a diaphragm cutting unit where the diaphragms can be arranged both in single row and in staggered rows. Possibility to equip any Сура С, Сура СД, Сура СДУ machines additionally with a string cutting unit given that the frame of all machine s are equipped with the connection elements.

Request for a quote

PKO-SURA COMPANY

Russia

Cooling of confectionery and bakery products before packaging is one of the most long-run (up to 5 hours or more) processes in production. The conveyor belt with the length of more than 300 m is necessary to transport the products during this time. Сура СKБ spiral conveyor is the best option for a conveyor system for cooling products for a long time. Due to the spiral geometry of the belt arrangement in space, it is possible to provide a large length of the belt in a minimum volume that essentially saves production space. In addition, the product is transported on a spiral conveyor belt as softly as possible, without rolling from one lay to another like in multilayered systems.

Request for a quote

DIRMAK MAKINA SAN. TIC. LTD. ŞTI.

Turkey

Dirmak Machinery ISM Series appeal many sectors to cater with a wide range of products from 10 litre up to 350 litre. Our machines provide to knead very short time thanks to excellent bowl and spiral apparatus design. Spiral mixer yields very quick preparation without warming and tiring products such as dough, mincemeat, cigkofte etc. ISM Series give power to your business with quite and smooth operation, durable and long-lasting.

Request for a quote

DIRMAK MAKINA SAN. TIC. LTD. ŞTI.

Turkey

We are producer of Planetary mixers from 10 L to 300 L. Main Specifications are floor model or bridge type model which are suitable for all kneading, mixing and whipping operations.Body painted with corrosion resistant electrostatical paint or AISI 304 stainless steel option. Powerful asynchronous motor with electronical speed variator. Water protected planetary system. Stainless steel bowl guard. Water proof button control panel with 60 minutes timer. Bowl position device allows the mixer to switch on only when the bowl and safety cover are properly positioned together.

Request for a quote

PKO-SURA COMPANY

Russia

It is designed for high-quality and uniform coating of various confectionery products with various types of glaze: chocolate fat sugar syrup, etc Due to the tank heating jacket and a mixing device, the glaze is heated to the operating temperature. The glaze is pumped into the glazing tank, and then the tank slide gates are opened and adjusted to obtain a straight, steady stream. The products to be glazed are placed on the feed conveyor and the conveyor is powered up. The products are transported on the large conveyor to the glazing area and then to the blowing area to remove excess glaze from the top. The bottom of the product is smoothed with the special rollers and then the products are transported to the cooling area. The glazing machine can be equipped with a decorator. Products can be glazed separately from the top, bottom or all sides. The machines for glazing with sugar syrup are manufactured considering some modifications necessary to operate the fast-hardening products.

Request for a quote

TURKIYE MACHINES BAKERY MACHINES

Turkey

This machine is designed with a rotating cone and adjustable spiral shaped corrosion resistant tracks around it. The dough becomes perfectly rounded while moving from bottom to top in the tracks which are adjustable. The machine is also equipped with a newly designed mechanical flour duster which does not make any noise while working. The standard rounding track is 4.5 meters. The weight range is from 100 gr. To 600 gr. Electric power 0.55 kw 220/380 V AC.50 Hz. It is also possible to produce 50 gr. To 200 gr. working capacity rounder machine. rounding track is 4.5 meters. The weight range is from 100 gr. To 600 gr. Electric power 0.55 kw 220/380 V AC.50 Hz. It is also possible to produce 50 gr. To 200 gr. working capacity rounder machine. Option Hot and cold air blowing system / Teflon coated channels or conic body / Electronic speed control

Request for a quoteResults for

Dairies - machinery and equipment - Import exportNumber of results

31 ProductsCountries

Company type