- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- conti

Results for

Conti - Import export

CONTI THERM S.R.O.

Czech Rep.

Induction heating of our CONTI type series is intended for for various applications of treatment such as brazing, melting, stamping, forging, hardening, annealing, tempering, straightening, and bonding –but especially for the heating of conductive metal materials. This rare technology is based on the creation of heat directly inside the worked-on product and it enables the use of the highest level of automation.

Request for a quote

YSTRAL GMBH MASCHINENBAU + PROCESSTECHNIK

Germany

The DaiTec offers all the advantages of the Conti-TDS technology and is specially tailored to the requirements of the milk processing and food industry. It is characterized by its 3A certified design and a powder feeding table with integrated hopper at an ergonomic working height. It is connected directly to existing containers and is ready for operation after a few simple steps. Due to its powerful suction vacuum, the machine can suck in and disperse directly from the powder container by means of a suction pipe in addition to suction from the hopper. It ensures dust-free container emptying, powder transport, powder introduction, powder wetting and dispersion. Agglomerate-free, highly concentrated, homogeneous and very stable dispersions due to the use of high shear energy and the wetting/dispersing of powders under vacuum. Excellent emulsifying properties - narrow spectrum of droplet size even without high pressure homogenizer. 3A-certified design

Request for a quote

SÜTHER & SCHÖN GMBH

Germany

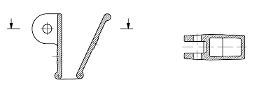

alternative (short) fixing-kit for Conti Polyflat and polyrope on request material socket housing: G20Mn5 material wedge: 226D

Request for a quote

SÜTHER & SCHÖN GMBH

Germany

Fixing-kit with wedge for Conti Polyflat and Polyrope optional with pin galvanized surface With type testing similar to EN 13411-6 material socke housingt: G20Mn5 material wedge: 226D material pin: 8.8 Please find certificates and instructions in our download area:

Request for a quote

YSTRAL GMBH MASCHINENBAU + PROCESSTECHNIK

Germany

The combination of different process steps in one machine provides you with great rationalisation potential: Production times are minimised, sub-processes are completely eliminated, production costs are reduced.The YSTRAL Conti-TDS is based on the same principle as the YSTRAL Inline Disperser. A special rotor-stator system generates a large negative pressure and absorbs powder, without dust formation and loss-free, directly into the liquid. The inducted powder is dispersed immediately and under high shear. Clean manufacturing process thanks to a dust and loss-free powder feed, even with powders that are difficult to wet, sticky or dusty Aspirating and dispersing of powders directly from silo (via buffer hopper), big bag, hopper, sack, barrel etc. Optimized result a better digestion, a higher effectiveness of the raw materials and a higher product quality.

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

The continuous non-contact Area-Weight Scale CONTI-SCALE X MULTIENERGY determines the panel weight and its distribution during production by measuring the area-weight and by taking the known panel dimensions into account. CONTI-SCALE X MULTIENERGY uses X-ray technology. Two X-ray tubes are located on a horizontal frame above the panel. The low energy X-ray beams are focused across the production width, but scan the full width of the panel. Metal plates on each side of the system prevent someone reaching inside the radiation area. There is no risk to human body parts which might stay beside/outside the system. The X-ray energy will be absorbed. Several detectors are lined up along the lower beam under the panel to measure (per track) the absorbed X-ray energy. This is how the area-weight is measured.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Conti - Import exportNumber of results

6 ProductsCountries

Company type