- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- chain conveyor

Results for

Chain conveyor - Import export

LANDA SAS

France

Discover our range of Conveyor chains for combine harvester and many other combine harvester parts on www.landa-partscenter.com. Landa offers a range of agricultural parts for forage harvesters, combine harvesters, balers, mower-conditioners, windrowers and tedders. We develop wear parts for harvesting machines that are equivalent to original manufacturer parts, in partnership with industrial companies specialising in the fields of metallurgy (assembly, machining, forming). Our range of spare parts is multi-brand: CLAAS, JOHN DEERE, NEW HOLLAND, KHUN, KRONE, FENDT etc. We work with well-known brands such as: GATES, OPTIBELT, NSK, NTN, TIMKEN, SCHAEFFLER, IWIS, DIAMOND, DONALSON, FLEETGUARD, MANN FILTER, SCHUMACHER, etc.

Request for a quote

ROBINSON CO.

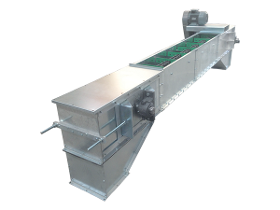

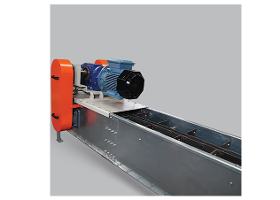

Turkey

Depending on the central control, it takes action by being set up with chain gear and ensures the transportation of the falling product. The body is made of steel. It has idler drive bearing system. It has been designed with a special tensioning device. It varies according to the desired capacities. Carrier plates are made of hardened steel. It is used wherever horizontal transportation is possible. It is used in feed, food, chemical, mining, sawdust and soil industries. Applications Fields ◾ Food industry ◾ Flour and semolina mills ◾ Feed mills ◾ Grain cleaning plants ◾ Corn processing plants ◾ Grain warehouses and silos ◾ Malt Factories

Request for a quote

PARSMEGA MAKINA

Turkey

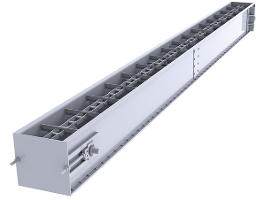

Chain conveyors are conveyor systems that drive chains and thus enable transportation of the material to be transported with equipment suitable for the material to be transported. Chain conveyors are high-strength carriers that transfer goods at high capacities. In chain conveyors, the chain appropriate to the size and weight of the material to be transported is selected. Chain conveyors consist of 3 main parts: drive section intermediate body tensioner section

Request for a quote

PARSMEGA MAKINA

Turkey

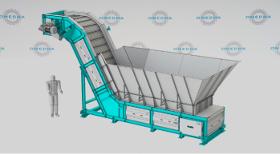

It is a carrier that allows raw materials and products to be transported horizontally and inclined to a certain degree in facilities such as feed, food, chemistry, fertilizer and soil.

Request for a quote

ROBINSON CO.

Turkey

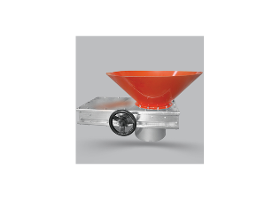

It is generally used as a dust collector, dust and air separator for the product. It is found in aspiration systems of cleaning machines. Dust removed by aspiration is separated from the air by means of a cyclone. The dust-laden carrier air is directed inside the separator thanks to the helical construction and is forced to rotate in the cyclone. Dust particles are dispersed to the environment with the effect of centrifugal forces arising due to rotation. Dust particles are carried along a helix path by means of the vortex created by the air pushed from behind. The clean air separated from the dusts goes through the suction pipe and goes to the outlet. Dust particles are directed downwards along the spiral due to the friction of the air against the wall. Applications Fields ◾ Food industry ◾ Flour and semolina mills ◾ Feed mills ◾ Grain cleaning plants ◾ Corn processing plants ◾ Grain warehouses and silos ◾ Malt Factories

Request for a quote

PARSMEGA MAKINA

Turkey

Our chain conveyors are designed to be used for many years and in many different application areas. Our chain conveyors, produced entirely from galvanized and superior steel sheets, are used to transport grain horizontally in grain storage systems. Many different application options are offered, depending on the field conditions and your needs. The right conveyor system for you is produced from 5 tons to 500 tons/hour depending on the condition, field conditions and capacity of your grain.

Request for a quote

TOSYALI MAKINA A.S.

Turkey

No other type of chain is as versatile as conveyor chains and our product range reflects this versatility. Bushing conveyor chains, roller conveyor chains, hollow pin chains, scraper chains, special conveyor chains for the paper industry and rotating chains are just some of the conveyor chains we can supply. Our product range also includes a wide range of special conveyor chains with straight, curved or U-shaped attachments and much more.

Request for a quote

HARVEST TRADING CHAIN COMPANY

Turkey

John Deere Grain Elevator Chain, John Deere Lexion Grain Elevator Chain, John Deere Harvester Combine Chain, John Deere Wheat Chain John Deere Conveyor Chain Orjinal No: AZ46269

Request for a quote

HARVEST TRADING CHAIN COMPANY

Turkey

John Deere Grain Elevator Chain, John Deere Lexion Grain Elevator Chain, John Deere Harvester Combine Chain, John Deere Wheat Chain John Deere Conveyor Chain

Request for a quote

HARVEST TRADING CHAIN COMPANY

Turkey

John Deere Grain Elevator Chain, John Deere Lexion Grain Elevator Chain, John Deere Harvester Combine Chain, John Deere Wheat Chain John Deere Conveyor Chain Orjinal No: DQ41476 Model: 1450/1470/1550 1570/W330 Brand: Donghua

Request for a quote

ILK IHRACAT AS.

Turkey

Our conveyor systems are designed to be the heart of Industry 4.0, the fourth industrial revolution that is transforming the manufacturing landscape. Industry 4.0 is characterized by the integration of digital technologies and automation into the manufacturing process, resulting in increased efficiency, improved productivity, and reduced costs. Our conveyor systems are at the forefront of this revolution, incorporating advanced technologies such as Internet of Things (IoT), artificial intelligence (AI), and machine learning (ML). These technologies enable our conveyor systems to collect and analyze real-time data, optimize production processes, and make intelligent decisions. With IoT capabilities, our conveyor systems can communicate with other machines and systems in the production line, creating a seamless and interconnected network. This allows for real-time monitoring and control, ensuring that any issues or bottlenecks are quickly identified and addressed.

Request for a quote

MAKENAS GRAIN MILLING TECHNOLOGY

Turkey

It is used mainly to convey all types of bulk material in the food industry,

Request for a quote

COMERC SP. Z O.O.

Poland

Redler type chain conveyors are designed for horizontal and inclined (up to 60°) transport of bulk materials such as pellets, sawdust, wood dust, wood chips etc. They are used as devices for loading and unloading silos, hammer mills, pellet mills and simultaneously for combining separate sections of technological lines. The drive section is equipped as standard with NORD company gear motors, rotation monitoring sensors and inspection hatches with overflow sensors. Drive shaft, on which flywheel is installed, is mounted in high-quality self-aligning ball bearings (SKF or SNR) Thanks to its construction tensioning section ensures constant optimum chain tension. Intermediate sections have length of 2000 mm as standard, but if necessary, section with non-standard length can be made. Bottom of conveyor is lined with antistatic, wear-resistant material (polyethylene PE 1000), which ensures low noise level.

Request for a quote

OMECHA UAB

Lithuania

Chain conveyors for tough material handling and transportation. Incline conveyors for the recycling industry. C&D waste recycling conveyors. Conveyor frames and drive modules are robust and heavy-duty equipment for the waste recycling industry.

Request for a quote

ZIMAS ZINCIR VE MAKINA SAN. TIC. A.S

Turkey

This type of Chains are designed according to customer demand and usage situation. Depending on the need, it is produced in such forms as steep-eared, bent-eared, weld-eared, welded L-twist-eared to be unilateral or double-sided on the chains, and used to transport the targeted products from one place to another. In general, it is a type of chain used for transfer purposes in conveyor belts.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

DAMBACH LAGERSYSTEME GMBH & CO KG

Germany

DAMBACH lift tables are efficient transfer units for mergers, crossings or branches in flows of materials. Roller or chain conveyors can be integrated as required. The interlocking lift mechanism combined with a rigid frame protects the unit loads and ensures optimum availability. As an option, variable intermediate lift positions can be included to ensure greater flexibility. The compact dimensions and safety guards expand the range of applications. Turntable with Roller or Chain Conveyor Turntables can divide or merge flows of materials without changing the orientation of the unit loads. The highly dynamic turntable drives from DAMBACH are interlocking units and ensure precise rotational angles of up to 270° with any number of intermediate stops. For optimum occupational safety, our turntables can be fully enclosed. In addition, the innovative modular design guarantees numerous and diverse applications and ease of servicing at the same time.

Request for a quote

IWIS ANTRIEBSSYSTEME GMBH & CO. KG

Germany

the context of the ELITE conveyor chain range, iwis suppliesa wide variety of chains according to standards DIN 8165 and DIN 8167, as well as models manufactured according to British Standard with dimensions in inches, and highly diverse special versions. Bush conveyor chains are often used for conveying tasks involving long transport distances at relatively low speeds. Since only a small minority of chains used in the industry are totally compliant with one specific standard, ELITE conveyor chains are custom-made to a specific customer order and consequently fulfil a large number of special requirements. Product range: • Bush conveyor chains according to DIN 8167 – M Series • Carrier chains with rollers according to DIN 8167 – MT Series • Hollow pin chains according to DIN 8168 – MC Series • Hollow pin chains according to DIN 8165 – FVC Series • Scraper chains according to DIN 8165/DIN 8167 • Conveyor chains for the paper industry • Rotary chains

Request for a quote

BEZNER ANLAGEN- UND MASCHINENBAU GMBH

Germany

Like belt conveyors, also a chain conveyor is engineered with the purpose of transporting materials. Transporting materials on this type of conveyor commonly proceeds in a horizontal way, but also vertically over a short distance to a higher level is possible.

Request for a quote

BEZNER ANLAGEN- UND MASCHINENBAU GMBH

Germany

For industries in waste treatment and recycling, we offer conveyor systems that include: Roller conveyors, Sliding conveyors, Speed conveyors, Chain conveyors, Transporting conveyors, Spiral conveyors, Bucket elevators, Bunker conveyors

Request for a quote

KINETECH DISTRIBUTION SRL

Romania

Welded chain for industrial application From 2mm to 60 mm diameter Hot dip galvanized, galvanized, stainless steel, painted, natural black

Request for a quote

FÖRDERTEC GMBH

Germany

The conveyor chain is the decisive factor for the functionality of each bulk goods conveyor system. The conveyor system can only be operated efficiently, if this conveyor chain withstands the high loads. Therefore, FörderTec uses a welding and production method for conveyor chains that is far superior to normal chains with respect to quality and durability. These forked lug chains are suitable for any application, even under the toughest of conditions. All forked lug chains are produced in our factory. We can react quickly and flexibly to each of your specific requirements. We are prepared for any eventuality – broken chain, emergency failure, system standstill. High-quality materials and special finishing methods make our conveyor chains extremely stable and fail-safe:

Request for a quote

LANDA SAS

France

Discover our range of Sprockets of conveyor chains for combine harvester and many other combine harvester parts on www.landa-partscenter.com. Landa offers a range of agricultural parts for forage harvesters, combine harvesters, balers, mower-conditioners, windrowers and tedders. We develop wear parts for harvesting machines that are equivalent to original manufacturer parts, in partnership with industrial companies specialising in the fields of metallurgy (assembly, machining, forming). Our range of spare parts is multi-brand: CLAAS, JOHN DEERE, NEW HOLLAND, KHUN, KRONE, FENDT etc. We work with well-known brands such as: GATES, OPTIBELT, NSK, NTN, TIMKEN, SCHAEFFLER, IWIS, DIAMOND, DONALSON, FLEETGUARD, MANN FILTER, SCHUMACHER, etc.

Request for a quote

UGUR MAKINA CRUSHING & SCREENING

Turkey

Apron feeders can operate horizontally or at an incline. In general, an Apron Feeder consists of overlapping abrasion-resistant pallets that are fastened on the chain with bolts, working like a conveyor. These chains, to which the pallets are attached, are driven by chain gears located on both sides

Request for a quote

PARSMEGA MAKINA

Turkey

Valves are generally used to control the product flow under flat-bottom silos with tunnel systems, chain conveyors and conical-bottom silos. It has a wide application area with its galvanized steel structure.

Request for a quote

ROBINSON CO.

Turkey

It is used to discharge or cut the flow of free flowing raw material or product to the desired terminal. It is used to discharge the product transported by the spiral using under the spiral to the appropriate parts. Reciprocating motion is performed by pneumatic piston or manually. The spiral is manufactured in different models according to the chain conveyor model. Two different models (pneumatic and manual) can be used at the outlets of silo and bunker with screw and chain conveyors. Applications Fields ◾ Food industry ◾ Flour and semolina mills ◾ Feed mills ◾ Grain cleaning plants ◾ Corn processing plants ◾ Grain warehouses and silos ◾ Malt Factories

Request for a quote

KRAUS BETRIEBSAUSSTATTUNG UND FÖRDERTECHNIK GMBH

Austria

Power-driven conveyor rollers are used with round belts, Multi-W belts, toothed belts or chain drives. Power-driven conveyor rollers can be used for goods with a wide range of load-bearing capacities.

Request for a quote

VENJAKOB MASCHINENBAU GMBH & CO KG

Germany

The chain-on-edge and spindle chain conveyor is used for the continuous or cyclic transport of workpieces. It's typical feature is its rotating spindles. The rotational movement of these spindles can be infinitely set. Typically, the rotational movement starts during the painting process; if desired, it can also be installed in the evaporation and drying zone. VEN TRANS system techniques enable tailor-made workpiece conveying and handling concepts. We create Our solutions take into account

Request for a quoteResults for

Chain conveyor - Import exportNumber of results

133 ProductsCountries

Category

- Chains (30)

- Harvesting machinery and equipment (20)

- Mechanical transmission systems and components (11)

- Conveyor belts (8)

- Conveyor systems (6)

- Lubricants, industrial (5)

- Machine tools, cutting - parts and accessories (5)

- Silicones (5)

- Oils, cooking - machinery and equipment (4)

- Packing and packaging - machinery and equipment (4)

- Sealing and wrapping - machinery and equipment (4)

- Goods handling systems, continuous (3)

- Storage equipment and systems (3)

- Wood veneer - machinery and equipment (3)

- Farm machines (2)

- Flour milling - machinery and equipment (2)

- Industrial design (2)

- Palletising machinery (2)

- Pallets (2)

- Pneumatic conveyor equipment (2)