- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- chemical dosing

Results for

Chemical dosing - Import export

COLLOIDE ENGINEERING SYSTEMS

United Kingdom

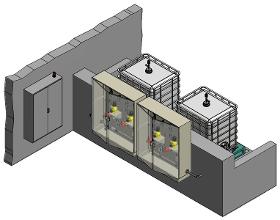

These packages are tailored to suit our clients’ requirements while adhering to European Standards, Ciria and HSE guidance. We engineer solutions to integrate into existing or new sites and can also provide packaged, standalone systems which are largely independent of the main plant. We provide solutions for chemicals such as sodium hydroxide, sulphuric acid, hydrochloric acid, ferric sulphate, aluminium sulphate, ferric chloride, antifoam, ortho-phosphoric acid, etc. Storage capacity, duty/standby configurations, materials of construction, etc. are tailored to the application, to provide adequate storage and ensure that the system can be operated and maintained safely. The chemical storage and dosing systems are fully fitted with instrumentation such as level controls, leak detection, flowmeters, etc. and are generally PLC controlled with an operator interface panel or PC used to allow the operator to view the plant operation and change parameters.

Request for a quote

HUGE PUMP

Turkey

USAGE AREAS : CHEMICAL INDUSTRY : Transfer of all kinds of acids from tanks to smaller tanks WATER TREATMENT INDUSTRY : Acid and alkali dosing for chemical cleaning in nano filters SURFACE PROCESSING SECTOR : In the circulation, filtration and transfer of surface treatment baths FOOD SECTOR : Transferring detergents and cleaners for wash equipments which are used in this industry such as pipes, bottles etc. CHEMISTRY PRODUCTION : Chemical transfer in industrial detergent equipment MINERAL TREATMENT SECTOR : Pure water circulation and transfer PHARMACEUTICAL SECTOR : Transfer of pharmaceutical raw materials

Request for a quote

NOVELTY STEEL

Turkey

A chemical dosing system comprises a comprehensive array of equipment designed for dosing, mixing, liquid transport, and automated control. It may also be referred to as a chemical feed system or dosing apparatus. This system finds application in various sectors such as power plant raw water treatment, boiler feed water management, oil field ground gathering and dehydration transportation systems, petrochemical dosing operations, and wastewater treatment processes.

Request for a quote

SOJET, LDA

Portugal

Innovative technology designed and developed especially to carry out the demanding hygiene processes of the food industry. The 2P NG satellite is a very robust and highly effective piece of equipment for applying cleaning products such as foams and disinfectants. Pressurized water is sent from the central unit, which allows the equipment to perform excellent rinsing as well as the controlled and rigorous application of chemicals. The dosing system has an easy-to-maintain stainless steel venturi. It also has giglers of different calibers, for precise application of the two products.

Request for a quote

SOJET, LDA

Portugal

Innovative technology designed and developed especially to carry out the demanding hygiene processes of the food industry. The FSmicro satellite is a very robust and highly effective piece of equipment for applying cleaning products such as foams and disinfectants. Pressurized water is sent from the central unit, which allows the equipment to perform excellent rinsing, as well as the controlled and rigorous application of chemicals. The dosing system has an easy-to-maintain stainless steel venturi. It also has giglers of different calibers, for precise application of the product.

Request for a quote

SOJET, LDA

Portugal

Innovative technology designed and developed especially to carry out the demanding processes of hygiene in the food industry. The FSmicro medium and low pressure satellites are very robust and highly effective equipment when applying cleaning products such as foams and disinfectants. The pressurized water is sent by the plant and in the case of from the FSmicro low pressure water is sent directly from the customer's network which allows the equipment to perform excellent rinsing as well as controlled and strict use of chemical products. The dosing system has a steel venturi Easy-to-maintain stainless steel. It also has giglers of different calibers, for a precise application of the product. The application in a stainless steel car allows all the technology

Request for a quote

BOSCH INDUSTRIEKESSEL GMBH - INDUSTRIAL BOILERS

Germany

The water analyzer measures residual oxygen concentration, pH values and conductivities of the boiler feed water and pH values of the boiler water. — For the fully-automatic measurement and monitoring of the boiler water quality — Increase in operating safety thanks to continuous monitoring of the water values — Automated monitoring with constant measurement of the pH value, oxygen content and conductivity — Savings on chemicals thanks to needs-based dosing of additives — Increased system efficiency through reduced desalting losses and saving of exhaust vapour energy — A water analysis device can monitor up to three boilers at a time and be integrated into plant control systems with control technology

Request for a quote

CDA

France

Fitted with a stainless steel conveyor, the CDA K-Net Auto linear automatic filler facilitates the automatic dosing and filling of various liquid types, ensuring strict adherence to hygiene standards. Tailored to accommodate diverse formats and a broad spectrum of products, the K-Net Auto finds applicability across multiple industries, including: Food Processing: Suitable for liquids like vinegar, oil, fruit juice, honey, and jam. Cosmetics: Ideal for products such as perfume, soap, ointment, and body oil. Paint and Varnish Industry: Efficiently handles buckets, paint, and varnish pots. Chemicals: Apt for dosing detergent, solvent, and similar products. Impressing users with its precision, user-friendly interface, and ease of cleaning, the K-Net Auto operates through an intuitive touch screen control system.

Request for a quote

DE WITTE SA

Belgium

Installed directly in the water supply line, Dosatron pumps operate without electricity, using water pressure as its sole power source. On its way through, the water activates the plunger, which takes up the required percentage of concentrate. Inside the pump, the concentrate is mixed with water. The water pressure forces the solution downstream. Once set, the pump requires no further attention. The dose of concentrate will always be strictly proportional to the volume of water entering the pump, whatever variations in flow or pressure may occur in the main line.

Request for a quote

DE WITTE SA

Belgium

Water driven. No need for electricity. Precise dosage independent of fluctuations in water flow or pressure. PVDF body available for aggressive products. Easy changing of dosing rate.

Request for a quote

WITTE PUMPS & TECHNOLOGY GMBH

Germany

Witte chemical pumps are used as dosing pumps for a variety of fluids. Pumps of the CHEM series are designed and assembled exclusively at the Tornesch site, thus guaranteeing highest reliability and quality. For all our series we offer a comprehensive spare parts service on request. In addition, we also install the pumps directly at our customer's plant. Dosing pumps of the CHEM series are extremely flexible in their design and can be offered in various variants and equipment thanks to a modular system. Differential pressures up to 120 bar, suction pressures vacuum up to 15 bar Temperatures up to max 500 °C in combination with a magnetic coupling. Viscosities up to 1.000.000 mPas or higher Components made of stainless steel, ceramic and special materials Flow rates from 20 l/h to 170,000 l/h

Request for a quote

ENDURAMAXX

United Kingdom

Enduramaxx’s Chemical Dosing Tanks available from 50 litres to 1500 litres storage capacity. Anyone who works with chemicals needs to store them safely and these moulded PE or PP tanks are specifically designed for use within the water treatment, purification, chemical dosing and storage applications. These bund tanks are designed specifically for use in the water treatment, effluent treatment and process control sectors, these are UV stabilised and available in black for use with chemicals such as Sodium Hypochlorite and suitable for Hydrogen Peroxide. These cylindrical chemical storage tanks include a flat raised section shelf section to mount equipment on top of the tank. This is ideal for mounting items such as chemical dosing pumps, industrial mixers, and instrumentation. Suitable for liquids up to 1.5 specific gravity.

Request for a quote

MPT DOSING GMBH

Germany

Customized plants and systems are our cup of tea. MPT plants are unique. They perform only one task: dosing or mixing chemicals. And yet they are always different. Namely, they are always perfectly adapted to your specific requirements.

Request for a quote

DC PRODUCTS

United Kingdom

Colour TFT display - 4 adjustable cycles - wash and rinse temperatures displayed, drain pump, break tank and chemical pumps fitted as standard - chemical dosing adjusted from control panel - heavy-duty wash pump - superior peristaltic detergent and rinse aid auto-dosing units - optional thermostop - insulated cabinet and door - double skinned boiler - extra usable wash height - low volume wash tank - EasyClean triple filter system - anti-block removable wash and rinse arms - moulded wash tank to prevent debris build-up and assist routine maintenance - simple, intuitive controls - self-draining wash pump for improved hygiene. 3 baskets.

Request for a quote

MPT DOSING GMBH

Germany

From left to right Dosing system for acid (left) and caustic (right). Sodium hydroxide-dosing system. Chemical-dosing systems are developed and manufactured for various applications and processes as complete, ready-for-connection function modules. Selecting the components and materials for constructing these systems requires long-year experience and comprehensive knowledge of the specific properties of the substances to be dosed. A lot of media are toxic and harmful to persons. Moreover, many are harmful to the environment and the groundwater. Substance properties such as a high viscosity or a high vapor pressure compromise the liability and a safe function if not considered when selecting and installing the pumps. For many years, MPT staff has been working in this specific area and gathered much experience when implementing hundreds of applications for nearly each topic in the range of premium dosing technology. From left to right Sulfuric acid-dosing station. Hardness

Request for a quote

ONURAY

Turkey

HT Bobbin dyeing machines are equipped with high technology that enables dyeing of any type of fiber made yarn in bobbin form. It is produced in different capacities (1 bobbin to 2000 bobbins) completely from AISI 316 quality Cr-Ni material. The maximum operating temperature is 140 ºC and the working pressure is designed as 4 Bar. The machines are equipped with high safety equipment (Mechanical, Electronic, Electro-Mechanical). Fully automatic machines with PLC control system have 5 ºC / min heating, 3 ºC / min cooling capability and can do chemical and dye dosing with PLC program. It is possible to dye muff, tops and fiber or yarn in different forms with different apparatus applications on the same machines.

Request for a quote

ENKI WATER TREATMENT TECH. LTD

Turkey

enki’s package water treatment plant (Compact water unit) is used to treat surface water supplies for the removal of suspended solid, color and coliform with classical water treatment process. Our package water treatment plant is pre-assembled in factory and ready to the site. Package water treatment plant is a compact and standardized unit for treated water demands of the small communities and industries. The plant capacity can be increased by adding skid mounted containerized modules. Package water treatment plant is mainly consisting of : coagulation, lamella clarifier, filtration, chemical dosing unit , control panel auxiliary equipment. All equipment will be mounted in the container or in skid. At site will be mounted the piping and electrical cabling between container.

Do you sell or make similar products?

Sign up to europages and have your products listed

VIRA ISI

Turkey

Dosing pots are required in order to feed liquid chemicals such as corrosion inhibitors into closed systems. The dosing pots consist of a mild steel vessel with an inlet (return) and outlet (flow) valves, a drain valve, and a filling valve. A steel tundish, air release valve, wall mounting brackets, and a non-return valve. Dosing pots can also be supplied without the valves, and air release valve if requested.

Request for a quote

DORU MAKINA VE DIS TICARET

Turkey

HT YARN DYEING MACHINE HT Package dyeing machines are equipped with high technology that enables dyeing of any type of fiber made yarn in cone form. It is produced in different capacities (1 cone to 2000 cones) completely from AISI 316 quality Cr-Ni material. The maximum operating temperature is 140 ºC and the working pressure is designed as 4 Bar. The machines are equipped with high safety equipment (Mechanical, Electronic, Electro-Mechanical). Fully automatic machines with PLC control system have 5 ºC / min heating, 3 ºC / min cooling capability and can do chemical and dye dosing with PLC program. It is possible to dye muff, tops and fiber or yarn in different forms with different apparatus applications on the same machines.

Request for a quote

NORTH RIDGE PUMPS LTD

United Kingdom

The RBT peristaltic hose pumps are high pressure positive displacement pumps, these range of pumps have a max design pressure of 15 bar, (150 metres), meaning they have the ability to transfer highly viscous fluids at long distances/high pressures making these range of hose pumps quite popular within the mining, construction, and slurry industries. Our RBT pumps are available with integrated frequency drives, VFD rated drive units, certified ATEX (explosion proof) motors, as well as hydraulic motors, these units are also equipped with reinforced hoses and rotors, heavily engineered integrated bearings, enlarged PU rollers as well as our patented clamping system making them suitable for pumping almost any fluid. Typical Applications & Industries: - Chemical Dosing - Water Treatment - Food/Beverage Transfer - Construction - Sampling - Mining - Paper Industry - Agriculture - Pharmaceutical - Industrial & Chemical Process Transfer – Glue, Resins, Ink, Paint, Dyes, - and More

Request for a quote

THOLANDER ABLUFTTECHNIK GMBH

Germany

Our crossflow scrubber reaches an optimum of flexibility. By flowing through various scrubbing stages consecutively, dust, acid or alkaline substances are removed within one plant. Flexibility Adaptation to your complex waste air Multiple stages in one housing Simultaneous elution of different contaminants Low construction height without waste loss Scrubbing stages sind nicht baulich getrennt Easy to maintain user interface Optimal consumption Efficient supply of fresh water Optimal dosing of chemicals Low pressure drop and low pump duty Reliable and fully automated operation Level switch in pump sump Dry run protection Monitoring of nozzle inlet pressure (Düsenvordruckes?) Fully automated, measurement driven control of chemical dosing Automatic desalination Frost protection for outdoor installation Low risk of clogging by choice of the right packing material Durable construction Plant components made of corrosion and chemical resistant FRP 30 years of experience Active...

Request for a quote

THOLANDER ABLUFTTECHNIK GMBH

Germany

Counter current scrubbers offer a competitive solution for "single substance problems". With our design we can ensure that contaminants will be removed efficiently from the waste air. Efficiency Little space requirements Separation result > 99% with heavily loaded waste air Little pressure drop because of heavy-duty packing material Easy to maintain user interface Dosing of chemicals as needed Optimized energy consumption Reliable and fully automated operation Level switch in pump sump Dry run protection Control of nozzle pressure Automatic, data controlled chemical dosing Automatic desalination Frost protection for outdoor installation Well thought out design Little pressure drop Little risk of clogging through choice of right packing material Plant made of corrosion-resistant and chemical-resistant FRP Big flexibility Optimized for varying raw gas loads No adjustment phase 30 years of experience Active references of each size Worldwide delivery, installation and service

Request for a quote

RICHARD ALAN ENGINEERING

United Kingdom

From a single bespoke pressure vessel to a complex turn-key factory expansion, a detailed design is essential in ensuring a smooth project delivery, on time and within budget. Clients come to us for our ability to provide simple answers to difficult questions - incorporating complex process pipework into a confined limited space, detailing requirements of operating conditions and calculations of loads, it’s all in a day’s work for our engineering design team. Whether a project involves structural steelwork or a complex chemical dosing system, we’re here to help and advise.

Request for a quoteResults for

Chemical dosing - Import exportNumber of results

24 ProductsCategory

- Pumps (4)

- Dosing - machines and equipment (3)

- Cleaning and maintenance - equipment and supplies (2)

- Dosing pumps (2)

- Gear pumps (2)

- Textile dyeing - machinery and equipment (2)

- Bag filling machinery and equipment (1)

- Boilers, industrial (1)

- Catering - machinery and equipment (1)

- Central heating systems (1)

- Engineering - industrial consultants (1)

- Pumps, hydraulic (1)

- Tanks, plastic (1)

- Textile dyeing (1)

- Water extraction - systems and equipment (1)

- Water treatment, industrial - systems and equipment (1)