- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- chipper

Results for

Chipper - Import export

TOSCANO AGRICULTURAL MACHINERY

Turkey

SHREDDER, also known as Flail Mower or Chopper, is used to shred plant wastes after the harvest. All the plant wastes and residues got broken in very little pieces. With this process, residues can dissolve in the soil easily. The process enhances soil microorganisms and improves the soil quality. It can be also used as a weed mower if needed. It also shreds wet plant wastes and stems. Foldable and wide working machines save time and fuel in large fields. -Universal 3point CAT II Linkage -1 3/8’’ Z6 Spline PTO Gearbox -750 rpm PTO Gearbox provides 1900 rpm Rotor Speed -5 Transmission belts; onepoint lubrication points for lubrication. -21cm height; 10 mm thick; Y blades. -Front chains for protection -2 mobile wheels with height adjustment -External adjustment for transmission belts

Request for a quote

TOSCANO AGRICULTURAL MACHINERY

Turkey

SHREDDER, also known as Flail Mower or Chopper, is used to shred plant wastes after the harvest. All the plant wastes and residues got broken in very little pieces. With this process, residues can dissolve in the soil easily. The process enhances soil microorganisms and improves the soil quality. It can be also used as a weed mower if needed. It also shreds wet plant wastes and stems. Foldable and wide working machines save time and fuel in large fields. -Universal 3point CAT III Linkage -1 3/8’’ Z6 Spline PTO Gearbox -1000 rpm PTO Gearbox provides 1900rpm Rotor Speed -5 Transmission belts; onepoint lubrication points for lubrication. -21cm height; 10 mm thick; Y blades. -Front sheets for protection -4 mobile wheels with height adjustment -External adjustment for transmission belts

Request for a quote

KAYU GROUP SOLUTION

Hungary

• Manufacturer:Ferrari • Year of construction : 2010 / completeley overhauled in 2017 • Type : L12T6 • Feed width:900 mm • Feed height : 450 mm • Rotor diameter : 1250 mm • Number of hogging knives: 6 pcs • 8 pcs of Feed rollers • Drive: 315 kW • Infeed vibrator : Type VR – 810 x 7000, • Complete switchgear • Price at location: 122.500 €

Request for a quote

COMERC SP. Z O.O.

Poland

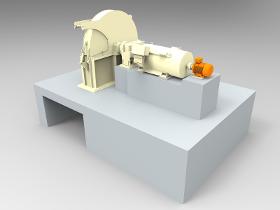

Skorpion 500 EBis a stationary drum chipper designed for chipping flat edgings, round timber, various types of furniture and sawmill waste of a width to 500 mm. The drive section of Skorpion 500 EB chipper is a45 or 55 kW slow-running electric motor. In contrast to high-speed motors, this motor is features more stable operation and higher torque. A slow-speed motor with the same power achieves greater energy transmission, and by increasing the diameter of the pulley on this motor, the service life of the V-belts is extended. The cutting system of the chipperincludes a drum with 2, 3 or optionally 4 cutting knives and 1 counter-knife. Screen used in the construction of this chipper ensures high regularity in size of the product. The required size of chips can be obtained by adequate configuration of suitable number of knives on the drum and the diameter of holes in the screen. The control system of the chipper consists of a control cabinet with functions of switching on, work control

Request for a quote

COMERC SP. Z O.O.

Poland

Skorpion 350 EB is a stationary drum chipper designed for chipping flat edgings, round timber, various types of furniture and sawmill waste of a width to 350 mm. The drive section of Skorpion 350 EB chipper is a 37 kW slow-running electric motor. In contrast to high-speed motors, this motor is features more stable operation and higher torque. A slow-speed motor with the same power achieves greater energy transmission, and by increasing the diameter of the pulley on this motor, the service life of the V-belts is extended. The cutting system of the chipper includes a drum with 2, 3 or optionally 4 cutting knives and 1 counter-knife. Screen used in the construction of this chipper ensures high regularity in size of the product. The required size of chips can be obtained by adequate configuration of suitable number of knives on the drum and the diameter of holes in the screen.

Request for a quote

STEINSTOSSER & SCHMACHTENBERG GMBH & CO. KG

Germany

Only the best for our forests Nowadays, forestry bears responsibility for numerous important tasks and is increasing not only in its commercial, but also in its environmental and social significance. In addition to continuous production of renewable raw materials (mainly wood) it is assuming the task of forest conservation, not least as a protected and recreational space for mankind and the animal kingdom. The predominantly municipal forestry operations are directed for the performance of these tasks at mobile woodcutters and robust wood chipping machines. We have supported the forestry industry for many years with our longlasting choppers and counterknives, as well as with shredder knives.

Request for a quote

COMERC SP. Z O.O.

Poland

Skorpion 650 EB is a stationary drum chipper designed for chipping flat edgings, round timber, various types of furniture and sawmill waste of a width to 650 mm. The drive section of Skorpion 500 EB chipper is a 90 or 110 kW slow-running electric motor. In contrast to high-speed motors, this motor is features more stable operation and higher torque. A slow-speed motor with the same power achieves greater energy transmission, and by increasing the diameter of the pulley on this motor, the service life of the V-belts is extended. The cutting system of the chipper includes a drum with 2, 3 or optionally 4 cutting knives and 1 counter-knife. Screen used in the construction of this chipper ensures high regularity in size of the product. The required size of chips can be obtained by adequate configuration of suitable number of knives on the drum and the diameter of holes in the screen.

Request for a quote

TONAR-EKSPORT

Russia

The blades made of highcarbon alloy steel have an exact attack angle and provide easy drilling. Due to the 5762 HRC hardness, the blades can be resharpened many times without losing their original properties. Advantages of our blades • The blades are manufactured on the hightech Italian grinding equipment MVM “La 500”; • Due to the finishing grinding operation, the blades are perfectly sharp and keep sharpening for a long time; • The blades are treated with the special protective compound. The blades suit the following augers and drills • Tornado • Buran • Motoshtorm

Request for a quote

TONAR-EKSPORT

Russia

The ICEBERG 160R ice auger blades fit the ice auger ICEBERG with a diameter of 160 mm and clockwise rotation. The blades made of highcarbon alloy steel have an exact attack angle and provide easy drilling. The hardness of 5762 HRC allows the blades being resharpened many times without losing their original properties. Advantages of our blades • The blades are manufactured on the hightech Italian grinding equipment MVM “La 500”; • Due to the finishing grinding operation, the blades are perfectly sharp and keep sharpening for a long time; • The blades are treated with the special protective compound.

Request for a quote

TONAR-EKSPORT

Russia

Helios is a folding ice auger with classical clockwise rotation, which is designed for holes drilling during winter fishing. The displacement of the upper and lower handles along the auger axis ensures smooth and effortless rotation of the ice auger with two hands at once and guarantees the fastest ice drilling. Highquality steel blades provide easy drilling. The Helios ice auger has a plastic screw wing with a steel core and plastic handles. The main product features are • Clockwise rotation • Drilling diameter 100±5 mm, 110±5 mm, 130±5 mm • Maximum drilling depth 1071 mm • Total length in working position up to 1544 mm • Bit length 445 mm • Transport Length 830 mm • Weight 2,42,6 kg

Request for a quote

TONAR-EKSPORT

Russia

TORNADO is a highquality, reliable ice auger with classical clockwise rotation and a telescopic extension pole. Being easy to use, it copes perfectly with ice drilling with maximum depth up to 1.5 meters. The displacement of the upper and lower handles along the auger axis ensures smooth and effortless rotation of the ice auger with two hands at once and guarantees the fastest ice drilling. The auger handles stay “warm” and comfortable even in severe frost. The ice auger can be converted to screwdriven by use of an adapter (sold separately). Polymer powder coating, which is applied using European hightech equipment, is one of the best in terms of mechanical resistance. The main product features are Clockwise rotation • Drilling diameter 130±5 mm, 150±5 mm, 180±5 mm • Maximum drilling depth 1490 mm • Total length in working position up to 2003 mm • Transport Length 945 mm • Weight 3,2 4 kg

Request for a quote

TONAR-EKSPORT

Russia

BURAN is a highly effective ice auger with classical clockwise rotation and a reliable seamless bit that provides fast cleaning of the hole out of the slush, requiring less effort. Its handle folding mechanism prevents backlash and makes it easier to get the auger into the working condition with one movement. Slipproof “warm” handles provide the best comfort during winter ice drilling. The reliable polymer coating withstands temperature fluctuations and heavy mechanical loads. Highquality steel blades provide easy drilling. The main product features are Clockwise rotation • Drilling diameter 100±5 mm, 130±5 mm, 150±5 mm, 180±5 mm • Maximum drilling depth 1490 mm • Total length in working position up to 1994 mm • Transport Length 926 mm • Weight 3,2 4 kg

Request for a quote

NITTO KOHKI EUROPE GMBH

Germany

The AIR CHIPPER are compact, lightweight and economical tools to have on hand for all kinds of chipping work. Easy chisel replacement is made to excellent operation. The straight design is suitable for operation at narrow and deep places. In addition, the ACH16 has many feature on the followings..... Idle running proof structure adopted. No blowing without touching the work piece by the chisel. Vibration on operation is reduced by low vibration structure. Especially effective on continuous operation. Easy to handle, compact lightweight type and weight only one kilogram

Request for a quote

NITTO KOHKI EUROPE GMBH

Germany

The AIR CHIPPER are compact, lightweight and economical tools to have on hand for all kinds of chipping work. Easy chisel replacement is made to excellent operation. The straight design is suitable for operation at narrow and deep places. In addition, the ACH16 has many feature on the followings..... Idle running proof structure adopted. No blowing without touching the work piece by the chisel. Vibration on operation is reduced by low vibration structure. Especially effective on continuous operation. Easy to handle, compact lightweight type and weight only one kilogram.

Request for a quote

WESTMARK GMBH

Germany

• 3 sharpened knife units and indentors (12x12 / 10x10 / 9x9 mm) • also for cutting fruit and vegetable sticks for finger food creations • the safe suction pad enables a secure hold • not suitable for sweet potatoes

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

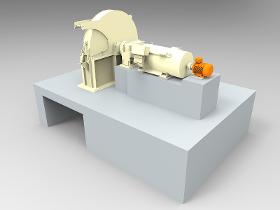

Drum chippers are used to process long and short logs, wood pieces, saw mill waste, veneer waste, residual wood, and other wood waste to high-quality chips. Depending on the size and design of the drum chipper, the machine can be adjusted to the type of wood to be processed and the desired chip quality. The most suitable chipper size is determined by the maximum trunk diameter to be processed and the desired production capacity. The desired chip length also inuences the performance of the chipper. Key features Adv Large draw-in rollers for process-reliable wood feed at constant speed Pivoting feed system for automatic adjustment to loading height Hydraulic ywheel drive for consistent contact pressure and the damping of impacts Robust, well-balanced rotor Large ywheel inertia to compensate for short-term peak loads Generously dimensioned V-belt drive Startup process via Pony-motor to reduce spikes in power supply during acceleration of the rotor

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

Disc chippers are especially suitable for processing straightly grown round wood into high quality wood chips. The raw material is fed into the chipper via a slanted horizontal feeding conveyor. The disc inside the housing is equipped with knives. The logs are processed to chips between the vertical rotor knives and the counter knives. The chips are discharged below via a discharge chute, with lling level control, to a subsequent conveyor. Advantages High, consistent chip quality Quick, ergonomic knife changes Cutting force supports material infeed Features, Function Chip length 20-25 mm Chip width 4-10 mm Options Adjusting devices for rotor and stator Knives

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

PALLMANN MASCHINENFABRIK GMBH & CO. KG

Germany

Drum chippers prepare long and short round wood, slabs, saw mill waste, veneer waste, board trimmings, and various waste wood into high quality wood chips. Annual plants such as cotton stalks or bamboo can also be processed. The drum chipper size and design can be tailored according to the wood type or infeed material to be prepared and the desired wood chip quality. The most suitable sized chipper is determined by the maximum infeed diameter to be processed and the desired throughput capacity. The required chip length will also influence the performance rate of the chipper. Characteristics, Function Large feed rollers assure a process reliable infeed at a constant speed Pivoted feed system for automatic adjustment of the infeed height Hydraulic swing drive system for constant pressure and shock absorption Robust, electrodynamically balanced chipper rotor Large flywheel effect to compensate for sudden peak loads Amply dimensioned V-belt drive Start process supported by...

Request for a quote

PALLMANN MASCHINENFABRIK GMBH & CO. KG

Germany

Drum chippers prepare long and short round wood, slabs, saw mill waste, veneer waste, board trimmings, and various waste wood into high quality wood chips. Annual plants such as cotton stalks or bamboo can also be processed. The drum chipper size and design can be tailored according to the wood type or infeed material to be prepared and the desired wood chip quality. The most suitable sized chipper is determined by the maximum infeed diameter to be processed and the desired throughput capacity. The required chip length will also influence the performance rate of the chipper. Characteristics, Function Large feed rollers assure a process reliable infeed at a constant speed Pivoted feed system for automatic adjustment of the infeed height Hydraulic swing drive system for constant pressure and shock absorption Robust, electrodynamically balanced chipper rotor Large flywheel effect to compensate for sudden peak loads Amply dimensioned V-belt drive Start process supported by...

Request for a quote

PALLMANN MASCHINENFABRIK GMBH & CO. KG

Germany

For the economical re-chipping of sawmill waste, veneer/plywood waste, screen oversizes and particleboard waste. The machine can be mounted e.g. under the chip screen without intermediate bin. Advantages Adaptability to various material Simple but heavy duty design Extraordinary sturdiness Low maintenance requirements High throughput capacity Low operation costs Quick screen and knife change

Request for a quote

PALLMANN MASCHINENFABRIK GMBH & CO. KG

Germany

Drum chippers prepare long and short round wood, slabs, saw mill waste, veneer waste, board trimmings, and various waste wood into high quality wood chips. Annual plants such as cotton stalks or bamboo can also be processed. The drum chipper size and design can be tailored according to the wood type or infeed material to be prepared and the desired wood chip quality. The most suitable sized chipper is determined by the maximum infeed diameter to be processed and the desired throughput capacity. The required chip length will also influence the performance rate of the chipper. Characteristics, Function Large feed rollers assure a process reliable infeed at a constant speed Pivoted feed system for automatic adjustment of the infeed height Hydraulic swing drive system for constant pressure and shock absorption Robust, electrodynamically balanced chipper rotor Large flywheel effect to compensate for sudden peak loads Amply dimensioned V-belt drive Start process supported by...

Request for a quote

PALLMANN MASCHINENFABRIK GMBH & CO. KG

Germany

For the economical re-chipping of sawmill waste, veneer/plywood waste, screen oversizes and particleboard waste. The machine can be mounted e.g. under the chip screen without intermediate bin. Advantages Adaptability to various material Simple but heavy duty design Extraordinary sturdiness Low maintenance requirements High throughput capacity Low operation costs Quick screen and knife change

Request for a quote

PALLMANN MASCHINENFABRIK GMBH & CO. KG

Germany

Drum chippers prepare long and short round wood, slabs, saw mill waste, veneer waste, board trimmings, and various waste wood into high quality wood chips. Annual plants such as cotton stalks or bamboo can also be processed. The drum chipper size and design can be tailored according to the wood type or infeed material to be prepared and the desired wood chip quality. The most suitable sized chipper is determined by the maximum infeed diameter to be processed and the desired throughput capacity. The required chip length will also influence the performance rate of the chipper. Characteristics, Function Large feed rollers assure a process reliable infeed at a constant speed Pivoted feed system for automatic adjustment of the infeed height Hydraulic swing drive system for constant pressure and shock absorption Robust, electrodynamically balanced chipper rotor Large flywheel effect to compensate for sudden peak loads Amply dimensioned V-belt drive Start process supported by...

Request for a quote

PALLMANN MASCHINENFABRIK GMBH & CO. KG

Germany

Drum chippers prepare long and short round wood, slabs, saw mill waste, veneer waste, board trimmings, and various waste wood into high quality wood chips. Annual plants such as cotton stalks or bamboo can also be processed. The drum chipper size and design can be tailored according to the wood type or infeed material to be prepared and the desired wood chip quality. The most suitable sized chipper is determined by the maximum infeed diameter to be processed and the desired throughput capacity. The required chip length will also influence the performance rate of the chipper. Characteristics, Function Large feed rollers assure a process reliable infeed at a constant speed Pivoted feed system for automatic adjustment of the infeed height Hydraulic swing drive system for constant pressure and shock absorption Robust, electrodynamically balanced chipper rotor Large flywheel effect to compensate for sudden peak loads Amply dimensioned V-belt drive Start process supported by...

Request for a quote

PALLMANN MASCHINENFABRIK GMBH & CO. KG

Germany

For the economical re-chipping of sawmill waste, veneer/plywood waste, screen oversizes and particleboard waste. The machine can be mounted e.g. under the chip screen without intermediate bin. Advantages Adaptability to various material Simple but heavy duty design Extraordinary sturdiness Low maintenance requirements High throughput capacity Low operation costs Quick screen and knife change

Request for a quote

PALLMANN MASCHINENFABRIK GMBH & CO. KG

Germany

Disc chippers are especially suitable for processing straightly grown round wood into high quality wood chips. The raw material is fed into the chipper via a slanted horizontal feeding conveyor. The disc inside the housing is equipped with knives. The logs are processed to chips between the vertical rotor knives and the counter knives. The chips are discharged below via a discharge chute, with filling level control, to a subsequent conveyor. Features, Function Chip length 20-25 mm Chip width 4-10 mm Chipping disc with large flywheel effect Robust, double-sided disc bearing Electro-mechanical locking during knife change Quick knife changes Re-grindable knives Advantages High, consistent chip quality Quick, ergonomic knife changes Cutting force supports material infeed Options Adjusting devices for rotor and stator knives

Request for a quoteResults for

Chipper - Import exportNumber of results

27 ProductsCountries

Company type

Category

- Hunting and fishing equipment and special products (5)

- Pneumatic conveyor equipment (3)

- Wood veneer - machinery and equipment (3)

- Agricultural machines and accessories (2)

- Tools, pneumatic (2)

- Components and parts for small household appliances (1)

- Sawmills - machinery and equipment (1)

- Steels and metals - forming and cutting (1)