- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- brick-making - machinery and equipment

Results for

Brick-making - machinery and equipment - Import export

SCANDINAVIAN & UK MACHINES

Sweden

Capacity – 1 concrete ring in 5-7 minutes. Technical description: Block height floor production: 500-1000 Useful height of machine: 1000 mm Production area: 1500 x 1500 mm Installed electrical power 25 kW Number of high-frequency vibrators: 6 pieces Machine weight with a mold and without a face mix device - 8750 kg Fully automatic model. "Scandinavian & UK Machines" provides full service in mobile and stationary batching plants; block, paving, curbs and wall panels producing equipment; cold asphalt plants; cement unloading equipment supply - consultations, projection, installation, specialists training, service, spare parts delivery.

Request for a quote

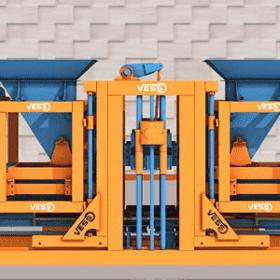

GLOBMAC GLOBAL BLOCK MACHINES

Turkey

The Pars18 Blocks Production line is designed and mad efor more operative and qualified production of blocks. The capacity of Machine per cycle is 18 of 20-th blocks on 1 pallet. Machine is full-automatical and controlled by PLC that is a big advantage for user. The equipment will ensure the production of quality products and operational work by stronger guides, an improved chassis of a Machine and powerful vibration motors. The power used by hydraulic units are playing the main role for production blocks on 140-150 pallets(cycles)/hour.

Request for a quote

NAMTAS CONCRETE BLOCK MACHINES AND CONCRETE PRODUCTS

Turkey

YB-1220 represents a new high-tech type of movable egg-laying concrete block machines, produced by Namtas since the beginning of 1980-s. This machine features high throughput and robust easy-to-use design. The machine moves on wheels along straight line on flat even concrete surface according to the specified program while moulding hollow, solid or insulated wall blocks from 185 to 300 mm in height directly on the floor. Delivery of fresh concrete from batching plant to the machine is done by a forklift equipped with a special hopper attachment. YB-1220 does not require production pallets and product handling systems to operate, minimizing customer’s initial financial input and reducing production costs. YB-1220 can be equipped with expanded polystyrene adding unit, allowing it to produce insulated wall blocks.

NAMTAS CONCRETE BLOCK MACHINES AND CONCRETE PRODUCTS

Turkey

NS-20 is the most compact automatic stationary concrete products machine Namtas manufactures. This reliable time-proven machine is made specifically for those investors and entrepreneurs, who want to start the production of the variety of concrete blocks with minimum financial input, while still being able to manufacture high-quality products, such as paving stones, curbstones, hollow and solid masonry blocks, filler blocks, rain gutters and hardscape elements from 60 to 200 mm in height. NS-20 is integrated in Type A concrete block production plants without automatic cuber. This means cured products should be transferred from production pallets to the transport pallets using manual labour.

NAMTAS CONCRETE BLOCK MACHINES AND CONCRETE PRODUCTS

Turkey

NS-30 and NS-25 are single-layer medium-pallet concrete block machines designed to manufacture high-quality concrete products, such as pavers, curbstones, hollow and solid wall blocks (including lightweight and insulated type), rain gutters and hardscape elements from 60 to 300 mm in height. The main difference between the machines is the size of vibration table, which is slightly bigger in NS-30. This increase machine’s production capacity for pavers and curbstones, as well as allows to produce 1 meter long curbstones lengthwise in the standing position. RIGID DURABLE FRAME AND PNEUMATIC MOULD BOX CLAMPING Both machines has a robust heavy-duty frame welded of rectangular steel tubes 150 x 150 mm. Mould and compaction head carriers are mounted on 4 80mm chrome-plated guiding columns. Mould is attached to the mould carrier via 4 airbags while compaction head is attached to the compaction head carrier via bolts.

Do you sell or make similar products?

Sign up to europages and have your products listed

TROUVERTOUTICI - MACHINE A PARPAING - FER A BÉTON - PORTE EN BOIS - CENTRALE A BÉTON

Turkey

10.2 AUTOMATIC MACHINE; Machine is designed to work 24 hours. Machine is very fast and has high production capacity through special servo motors. By changing the mould machine can produce any types of Concrete Paving Blocks-Hollow Blocks - Insulated Bricks – Different Curbstones – Asmolen And Chimney Blocks which height must be between 2cm and 40 cm. Equipment list with prices, prepared related to the installation layout is given below. Daily capacity (8 hours) 700 m² Paving Blocks / 10.000 Pieces Concrete Hollow Blocks... 10.2 AUTOMATIC MACHINE; The price of the campaign is prepared as complete plant “Turnkey Project”. Except product drying and curing rooms there is no extra equipment needed on the plant area. For a plant of the with these features the recommended installation , curing and stock area is minimum 3.000 m2. There is no obligation for roofing. The prepared concrete floor should be minimum 1/3 of the plant area.

Request for a quoteResults for

Brick-making - machinery and equipment - Import exportNumber of results

7 ProductsCountries

Company type

Category