- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- custom rubber mouldings

Results for

Custom rubber mouldings - Import export

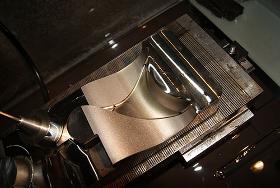

DLR ELASTOMER ENGINEERING

United Kingdom

At DLR Elastomer, we pride ourselves on offering a bespoke custom rubber moulding service, understanding application requirements, designing the parts, tooling & process to deliver the product to the clients’ exact and demanding performance needs. Our technical team is happy to advise on materials best suited for your application. Where necessary, we can modify the existing compound and/or develop new compounds keeping the service performance conditions of your product in mind. In addition, we monitor and apply current developments in polymer technology and we use this knowledge to develop even more advanced materials which will benefit our customers. Dlr Elastomer Engineering Rubber component design can be critical to its performance. We offer advice on all aspects of product design, helping to enhance performance & service life. Working from a sample, sketch or drawing, we can quickly select the materials required to provide a quotation for parts and associated tooling.

Request for a quote

DP SEALS LTD

United Kingdom

DP Seals manufacture precision custom rubber mouldings designed and manufactured to the highest possible tolerances. This includes simple products right up to hugely complex dual material, conductive and semi-conductive rubber components. We specialise in transfer and compression moulding and also have expertise in rubber to metal bonded seals and mouldings.

Request for a quote

N&H TECHNOLOGY GMBH

Germany

We realize with customized plastic moldings. Our product spectrum ranges from the smallest precision parts through housings to complex multi-component parts. On the basis of your sample, your specification or technical drawing, we will create an individual offer and support you during the project. We advise you on the selection of suitable materials and offer cost reduction options. We offer you an active co-operation in the development and construction and give suggestions for improvement. For an offer we need: •technical drawing, sketch or pattern •technical specifications, equipment extras •required amount Please send following informations to: info@nh-technology.de One of our engineering experts will contact you asap.

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

Ming Xiao Mfg engaged in custom plastic molded parts by plastic injection molding more than 15 years, our factory is from Ningbo China, we can custom all kinds of plastic molded parts,steel pins inserted plastic parts. We have a variety of injection molding machines, large injection molding machines and small injection molding machines, vertical injection molding machines and horizontal injection molding machines, according to the type and structure of plastic components to choose the most suitable machine to produce, thus saving production and improving production efficiency and quality assurance. Plastic parts is very simple & popular in all industries, such as plastic cover, plastic knob,plastic bracket,plastic flange,plastic valves,plastic gears,plastic bushing,plastic base,plastic shafts,plastic mountings, plastic coupling,plastic fabrications,etc. Plastic injection molding is suit to complicated plastic parts with complex profile or structure, welcome contact us for quoting!

Request for a quote

DLR ELASTOMER ENGINEERING

United Kingdom

The well known under-bonnet temperature increase has been resolved mainly by using high-performance polymers with the capability of withstanding temperatures in excess of 200°C. Some of the rubber mouldings commonly encountered in a car include O-rings, seals and grommets. Rubber mouldings are required to resist oils and greases as well as dirt, water, and weathering. Many custom rubber moulding solutions are subject to dynamic loading, including engine mounts and exhaust hangers. Applications requiring the best oil and chemical resistance and good ageing in hot fuel vapours are accommodated using high-performance fluoro (FKM) and fluorosilicone (FVMQ) elastomers. The bonding of rubber to other substrates is a crucial part of being able to offer novel solutions.

Request for a quote

N&H TECHNOLOGY GMBH

Germany

We manufacture customer-specific molded parts made of rubber, silicone and elastomer composite parts in small and large series production according to your sample or drawing. Molded rubber parts are generally characterized by their good formability, chemical resistance, pressure and abrasion resistance and good electrical properties. We advise you in detail on the selection of the suitable material, with a view to the functional description, temperature resistance, chemical requirements, weather influences and resilience. Our molded parts are used in all industries, such as the automotive industry, medical technology, mechanical engineering and electronics industry. We offer customized parts: Protective covers for input devices, Rubber seals and rings, Grommets, flanges, bellows, Form Tubes, Rubber damper, PU molded parts (e.g. wheels and rollers) Combined rubber-metal parts / rubber-plastic parts, etc.

Request for a quote

REP INTERNATIONAL

France

The V310 is available as standard with a Y400 or Y1000 injection unit. It is distinguished by its very small footprint Machine features: - Clamping force: 1,100 kN. - Platen size: 335 x 400 mm. - Injection volume: 400 or 1000 cm³.

Request for a quote

REP INTERNATIONAL

France

In order to be able to offer other alternatives, the REP offer is being expanded with localized, high-performance and economical solutions. Manufactured in China and India, our G9A and URP ranges are specially designed for the Asian market. The G9A range consists of : - V49A Clamping force 1600 kN. Size of the platens 430 x 510 mm. Injection volume 1000 cm³. - V59A Clamping force 2600 kN. Size of the platens 500 x 630 mm. Injection volume 1000 or 2000 or 5000 cm3 - S59A Clamping force 3000 kN. Size of the platens 560 x 780 mm. Injection volume 1000 or 2000 or 5000 cm3 - S709A -Clamping force 5100 kN. Size of the platens 630 x 800 mm. Injection volume 2000 or 5000 or 8500 or 11000 cm3

Request for a quote

REP INTERNATIONAL

France

Part of our entry-level range, G9A machines combine REP's expert know-how and Indian skills

Request for a quote

PHILPLAST LTD.

Bulgaria

Our tooling engineers and designers have extensive experience in creating various blow molds and injection molds. Our in-house tooling department produces molds for most plastic articles made in Philplast as well as molds for use outside our company. We can design, produce and issue technical documentation before the mold making, or we can make molds from 3D documentation provided by the client. In our tooling production we use new fully equipped high-performance CNC machines. The maximum size of our blow molds is for articles up to 20 liters in volume. The maximum dimensions for our injection molds are 546 x 896mm with a maximum weight of 2,500kg. All molds made to be used in Philplast are thoroughly tested on out machines to ensure their perfect quality.

Request for a quote

REP INTERNATIONAL

France

V79 : a model with innovative ergonomics : no pit for the press, no platform for the operator. This customized V79 is used for large volume bi-material injection with automatic loading and demolding.

Request for a quote

REP INTERNATIONAL

France

Particular features of the machine Different demolding possibilities the mold can be opened automatically, possible infeed/outfeed of the lower mould half or rail system. Upper and lower ejectors for the full kNockout of the molded parts. Adjustable inclination of the top platen. They are particularly suitable for moulding Orings, pharmaceutical stoppers, syringe plungers, and many other rubber parts. They are available in 2RT or 3RT series depending on the number of plates in the mould.

Request for a quote

REP INTERNATIONAL

France

Machine features Clamping force 500 kN. Size of the platens 300 x 300 mm. Injection volume 125 cm³.

Request for a quote

RICHARD PIERIS EXPORTS PLC

Sri Lanka

We are capable of manufacturing a range of customized and specialized rubber molded product, Our crutch tips are one of the products we manufacture, currently, we look for more product inquiries to start producing more rubber molded products.

Request for a quote

BOSCH MANUFACTURING AND SERVICES BELGIUM

Belgium

We have proven experience in (seamless) injection molding, both on natural as synthetic rubber types. Tooling design is also done in-house.

Request for a quote

GPMFG

Canada

GPMFG provide efficient, reliable, and high-quality silicone rubber molding solutions for your products.From Tooling/Molds design,manufacturing to molding productiong. Products/Parts Analysis & Optimizing Tooling/Molds Development & Manufacturing Compression Molding Of Solid Silicone Rubber Injection Molding Of Liquid Silicone Rubber Insert Molding Of Silicone Rubber Overmolding Of Silicone Rubber Diverse Post Processes Available Minimum Order Of 1 - 100K+ Parts Get Silicone Parts Within 5 Days Get A Quick Quote In Less Than 12 Hours Complex Elastomer Parts & High Level Of Detail

Request for a quote

CRAFTMACH ENGINEERED SOLUTIONS INC.

Canada

Hello, let's improve the company performance and profitability with our committed help, products and solutions by 10-25%. We can manufacture and supply high quality standard and custom injection molding nozzle tips with guaranteed quality and unbeatable price. Please get in touch with more details and attractive pricing. CRAFTMACH Tool Steel Tips are made from High Quality Wear Resistant H-13 Alloy Tool Steel. All Nozzle Tips are as per Industry Standards and Fit All Competing Adaptor Bodies. The Hardness Is 46-48 RC. Other Alloy Tool Steel Materials and Sizes Nozzle Tips are also available as per Customer Requirement. WHY CRAFTMACH NOZZLE TIPS? •Guaranteed Performance & Work Life •High Quality Wear Resistant Tool Steel •Industry Standard and Compatible Fit •Super Finished and Highly Polished •Hardened and Tempered as Per Requirement •Custom Nozzle Tips are Available On Request

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

PET TECHNOLOGIES

Austria

Automatic blow molding machine for PET bottles with volume 0.2-2.0l and output 3 000 bph. Patented mold closing system: 1500 bph from one mold cavity. CE certificate and conformity to HACCP. Technical data Output up to 3 000 bph Bottle volume 0,2 – 2,0 l Blowing pressure 8-10 bar Low pressureup to 40 bar Low and high pressure air demand1,3 m³/min for bottle 1.5 l Cooling liquid temperature 7-9 °С Voltage supply400 V / 50 Hz Installed power 41 kW Overall dimensions6400 х 2800 х 2300 mm Weight ~ 2 350 kg (*1,5 liter with 30-35 gr. PCO-Preform)

Request for a quote

OBRT HARI-PLAST

Bosnia and Herzegovina

we have machines from 50 to 550 tons of closing force and blow moulding machine up to 2 liter. We can make injection moulded parts up to 1100 gr. We offer serviced production of injection molded and blown parts with quality and fast delivery. o Our company is located in Bosnia and Herzegovina. Proximity to European countries means low transport costs and short delivery times. Kontakt: info@hariplast.com

Request for a quote

PET TECHNOLOGIES

Austria

Universal semiautomatic blow molding machine for PET bottles 0.2 – 10.0l with output 800 bph. Easy to adjust and maintain. Technical data Output 600-800 bph with volume of 5-6 l 250-350 bph with volume of 7-10 l Neck diameter28-48 mm Bottle volume0,2-10,0 l Blowing pressure8-10 bar Low pressure15(up to 25) bar Low and high pressure air demand0,8m³/min for bottle 1.5 l Cooling liquid temperature 7-9 °С Voltage supply400 V / 50 Hz Installed power 23 kW Overall dimensions1425х800х2300mm 1700х600х1720mm Weight 700+225 kg

Request for a quote

PET TECHNOLOGIES

Austria

Automatic blow molding machine for PET bottles with volume 3.0-10.0l and output 1 600 bph. Two independent blowing units to produce 2 bottle formats by turns. CE certificate and conformity to HACCP. Technical data Output1 600 bph with volume of 3-8 l up to 1 200 bph with volume of 10 l Bottle volume3,0 – 10,0 l Blowing pressure 8-10 bar Low pressureup to 30 bar Low and high pressure air demand5,0m³/min Cooling liquid temperature 7-9 °С Voltage supply400 V / 50 Hz Installed power 46 kW Overall dimensions7400 х 3200 х 2720 mm Weight ~ 4 600 kg (*preform 67-85 gramms)

Request for a quote

BESTONE TECHNOLOGY LIMITED.

China

This is our workshop is fully automatic production of 16 Cavities PC material products.

Request for a quote

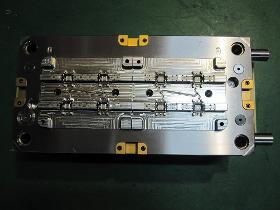

BESTONE TECHNOLOGY LIMITED.

China

Precision injection tooling-1 cavity side and 3 core side-this is core side-2.

Request for a quoteResults for

Custom rubber mouldings - Import exportNumber of results

24 ProductsCountries

Company type