- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- electropolishing

Results for

Electropolishing - Import export

ANOPOL LTD.

United Kingdom

Electropolishing is in effect electroplating in reverse. Instead of depositing a coating of another material on a surface the process of electropolishing is to remove a surface layer, typically 20-40 micro-metres in depth in the case of stainless steel.

Request for a quote

STEROS GPA INNOVATIVE, S.L.

Spain

DLyte eBlast is an electropolishing equipment that offers a stream of solid-electrolyte particles propelled by a non-conductive liquid media to improve the surface quality of metal pieces. This electrochemical surface finishing process is especially designed to surface finish large or heavy parts, or with complex geometries which are difficult to polish by immersion or that require a localized finishing, like welded areas. The new electro-blasting technology is perfect for blind holes, slots, occluded areas and inner channels. This new way to apply electropolishing allows a focused surface finishing, as the media is projected towards a localized area of the piece. DLyte eBlast joins together some benefits in comparison to other surface finishing technologies. The main advantages are that this process can be applied locally in the required area. The process improves the final appearance of metal parts, with no pitting on the metal surface.

Request for a quote

STEROS GPA INNOVATIVE, S.L.

Spain

DLyte Desktop Series have been designed in 2021 to improve the work environment of small companies by replacing the manual polishing of metal parts or with equipment that uses hazardous materials for workers. The new equipment gathers all the advantages of any DLyte system currently available and allows any company to access the dry electropolishing technology, including those companies that need a cost-effective solution for metal surface finishing processes. Due to its small dimensions (450 x 521 x 471 mm), its price and the fact of not requiring a special pre-existing electrical or compressed air installation, DLyte Desktop Series are affordable to any kind of company. Moreover, thanks to its intuitive software, it is a good choice for any professional needing to automate metal finishing processes. DLyte Desktop Series are suitable to polish CoCr (with DLyte Desktop Dental) and CoCr and Ti (with DLyte Desktop PRO).

Request for a quote

SISTO ARMATUREN S.A.

Luxembourg

SISTO-C Manually operated Valves Diaphragm size 40-115 Features ● Plastic handwheel PA6GF30 ● Handwheel with recessed grip ● Stainless steel position indicator ● Non-rising handwheel ● Electropolished stainless steel bonnet ● Stainless steel compressor ● stainless steel stem ● Autoclavable ● Floating nut ● Stainless steel spiral Support for MD65 and larger Options ● Stainless steel handwheel ● Adjustable travel stop in closed direction ● Adjustable travel stop in open direction ● Limit Switches ● Locking device ● Stem extension

Request for a quote

SISTO ARMATUREN S.A.

Luxembourg

SISTO-C Manually operated Valves Diaphragm size 30 Features ● Plastic handwheel PA6GF30 ● Handwheel with recessed grip ● Integrated travel stop in close direction ● Stainless steel position indicator ● Rising handwheel ● Electropolished stainless steel bonnet ● Stainless steel compressor ● stainless steel stem ● Autoclavable ● Floating nut Options ● Stainless steel handwheel ● Limit switches ● Stem extension

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ANOPOL LTD.

United Kingdom

Stainless steel derives its corrosion resistant properties from a thin oxide film on the surface, often referred to as a passive layer. Surface contamination can prevent the formation of the passive layer and cause stainless steel to corrode. Heat tint or weld burn discolouration are such surface contaminants and require removal.

Request for a quote

ANOPOL LTD.

United Kingdom

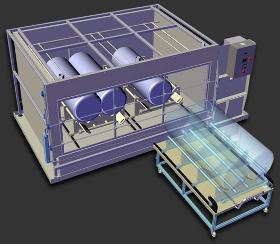

Anopol can design, build and install plant and equipment for customers to carry out their own electropolishing, pickling & passivation.

Request for a quote

ANOPOL LTD.

United Kingdom

Anopol offer comprehensive in-house and on-site subcontract services for cleaning, pickling, passivating and electropolishing of Stainless Steel with projects having been carried out by our site teams in the UK and throughout the world.

Request for a quote

ANOPOL LTD.

United Kingdom

The ANOPOL range of products for Cleaning, Pickling and Passivating stainless steels removes contamination, improves corrosion resistance and can produce a clean, aesthetically attractive appearance. In addition ANOPOL offers 2 types of Test Kits, one for checking the presence of free iron on a surface and the other for differentiating between grades 304 and 316.

Request for a quoteResults for

Electropolishing - Import exportNumber of results

10 ProductsCountries

Company type