- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- extrusion

Results for

Extrusion - Import export

STANDART ALUMINIUM

Turkey

Aluminum profiles are produced for use in various sectors and for different purposes, with our 1100 UST 5 ” and 1650 UST 6” extrusion lines in Standard Aluminum facilities integrated with the latest technology . First class aluminum billet raw materials used in our extrusion lines consist of 6xxx series alloys. The extrusion process can be briefly defined as taking the shape of the mold and lengthening the profiles by passing large aluminum billets under high temperature and pressure through aluminum extrusion molds made of special steels at high temperature.

Request for a quote

W. MÜLLER GMBH

Germany

Space-saving in a vertical (e.g. for retrofitting) but also in a horizontal version, our extruders are available in many variations for your specific needs. For applications with larger throughputs, we have high-quality extruders with heat-separated feed zone cooling, which deliver a high-quality melt for the further process. We also offer coordinated screw designs for special materials such as PVC, PA, EVOH, E-PET or adhesive layers.

Request for a quote

GOLDEN COMPOUND GMBH

Germany

GC green 2012-91 MI T15 contains 20% natural fibers and is a biomaterial - allrounder for various extrusion applications. With GC green you get a resource-saving and home-compostable material with ground sunflower seed hulls. The fibers from sunflower seed hulls are a by-product of sunflower oil production. They are GMO-free, do not compete with food and do not require additional acreage. Often this material has already been used for various biodegradable labels. In order to provide you with an optimal color selection, we have had 10 masterbatch colors certified by TÜV Austria. We will be happy to advise you. Further advantages of GC green: 100% recyclable Reduced cycle times No sink marks Lower energy input In addition to our allrounder compounds, we naturally have many other material formulations. Just contact us, together we will find the perfect compound for your application.

Request for a quote

ROLF KÖRNER GMBH

Germany

Filter belts are used for a continuous filtration of polymer melt. These filter belts, but also wire mesh pre-cut parts, are manufactured in various dimensions and weaves. For high demands the fabrics are available with high tenacity warp wires. Plasma cut edges assure a continuous and frictionless passage of the filter belts Materials:Stainless steel, plain steel, combinations of various materials.

Request for a quote

ROLF KÖRNER GMBH

Germany

We produce filter discs and cuttings in any measurement and shape from wire cloths and metal fiber felts. All products can be ultrasonically cleaned, if requested!

Request for a quote

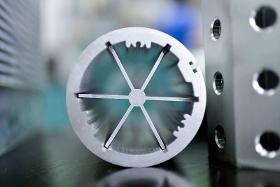

PLANSEE SE

Austria

Molybdenum-hafnium carbide (MHC) is highly temperature-resistant, has a high level of thermal conductivity, a low coefficient of thermal expansion and a high recrystallization temperature. MHC retains its shape even when used at temperatures of up to 1 550 °C. At temperatures up to 800 °C, MHC is suitable for use in die inserts. At higher temperatures, the producer recommends using MHC for full dies. The benefits to you for a long service life: — Optimum nondeformability and dimensional stability — Low tendency to crack in the case of edged profiles — High thermal stability — High thermal conductivity — Low thermal expansion — Good hot ductility — Very high recrystallization temperature Plansee supplies MHC components in disc form with or without drilled start hole.

Request for a quote

AV ALUMITRAN S.L.

Spain

The aluminium extrusion process uses a press to shape a hot aluminium billet by means of compression. The profiles resulting from the billet that flows through the die at a temperature of 500ºC are laid out, cooled and stretched on a roller bed, subsequently moving towards the saw where they are cut to the desired size.

Request for a quote

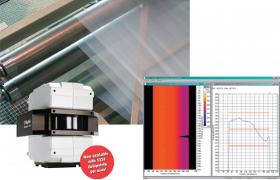

FLUKE PROCESS INSTRUMENTS GMBH

Germany

Thermal imaging system based on the Raytek MP150 infrared linescanner. Detailed web temperature profile based on 40,000 measurement points per second Automated temperature monitoring Automated quality monitoring for ISO9000 Ensures proper web temperatures for strong film-to-substrate adhesion Enables plant operators to reduce scrap and improve profitability and product quality Quick and automatic detection of “wavy” or “running” edges, gaps, and torn edges Define product-specific configurations (recipes) Automatically analyze “automatic sector” temperature distributions Visualisation on PC Playback stored files as “movie” Multiple language support Integrated OPC server for remote system control Ethernet TCP/IP interface integrated in the line scanning system PC-independent alarm output Analog outputs 3 x 4 – 20mA Analog or digital output modules For sheet extrusion see the Raytek ES150 system.

Request for a quote

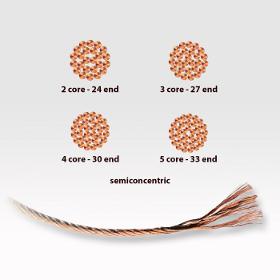

LEONI DRAHT GMBH

Germany

Strands with a semi-concentric structure made from Cu-ETP1, Cu-OF1 and LEONI Histral® alloys in bare, tin-plated, nickel-plated or silver-plated, soft annealed. Single-wire diameter ranging from Ø 0.05 mm to Ø 0.51 mm, left-hand lay or right-hand lay. Cross-section ranging from 0.03 mm² to 16 mm². The individual wires are subject to an exact positioning, yet without an additional core wire, which ensures an all-out uniform structure. Concentric strands are particularly appropriate for thin-gauge coating with high-grade isolation materials (extrusions). The technical qualities of a semi-concentric strand can be extremely well and accurately customized by combining several different alloy wires.

Request for a quote

HEXPOL TPE GMBH

Germany

In the extrusion process the TPE pellets are poured into a hopper are heated in the barrel and turned into a melt by this heat and shear. A screw carries the melted plastic through a shaped die to produce continuous lengths of shapes with the same profile, which are then cooled by air or water. Our TPE compounds are easily extruded into single and complex profiles. They can also be co-extruded with other materials to yield a part with both rigid and soft components. They exhibit improved profile flexibility. The SEBS compounds, with their saturated intermediate blocks, are very stable against thermal degradation. On the other hand, the SBS compounds degrade if overheated or if a screw with excessively high compression ratio is used. The information below is intended as a general overview, settings may vary depending on the specific grade selected. Please CONTACT US for detailed processing information SEBS based materials Equipment Extruders used for polyolefines are best for TPE comp

Request for a quote

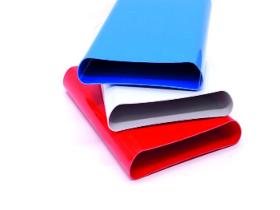

SEPA ALUMINYUM VE METAL SAN. TIC. AS.

Turkey

SEPA baffle ceiling systems; are an open ceiling system that consists of U type panels which has 10100mm base and 40600mm height. Various models of baffles can be used in order to give different shades and angles for the architects and customers allowing limitless space for design. Baffles are linear panels installed in one way to increase the sight of the location. This models are widely used to keep same volume perception while decreasing the level of the ceiling. Panels can also be produced with wood effect while having much more advantages that the actual wood like easy maintanence and long durability.

Request for a quote

ANCHOR MAGNETS LTD

United Kingdom

We produce and stock, as standard, an extensive range of magnetic profiles in numerous shapes and dimensions. We also extrude custom profiles to meet specific requirements. Thanks to our experience and manufacturing capabilities we can extrude a profile of any shape, and if required, adjust the composition of the magnetic material to create different pull strengths for specific applications.

Request for a quote

FRÄNKISCHE INDUSTRIAL PIPES GMBH & CO. KG

Germany

Our custom blow molded parts such as containers, air conduction tubes, connection tubes and drainage tubes are 3D blow molded, suction blow molded and manipulated by a robot (3-D Roboter Blow Moulding Machine). They are 100 percent leak-proof and guarantee consistent wall thickness. Since the blow molds are developed by and tailored to customer specific requirements, a perfect fit is guaranteed, the number of assembly steps is reduced, weight is reduced and the risk of leakage is minimized. Available materials / maximum operating temperature: PE / -40°C up to + 70°C PP / -40°C up to +105°C Dimensions: max: 900x500x300mm min: 50x20x100mm eight/pc.: 10-3.000 Gramm diameter: min. 8-10 mm Application: Industrial applications, such as home appliances, air conditioning, medical technology, etc.

Request for a quote

UMIT ALUMINIUM

Turkey

All of your aluminum products are produced in our extrusion factory, from architectural systems to all other sectors. We always meet the demands of our customers by keeping the minimum production amount limited to 500 kilos. In our electrostatic powder coating, we paint your products in the colors you want with high quality and deliver them to your address wherever you are in the world. In addition, we advertise your product by printing the company logos of our customers on the sticker and sticking them on the products. We guarantee that our prices will be the best you can find and the best service.

Request for a quote

UMIT ALUMINIUM

Turkey

All of your aluminum products are produced in our extrusion factory, from architectural systems to all other sectors. We always meet the demands of our customers by keeping the minimum production amount limited to 500 kilos. In our electrostatic powder coating, we paint your products in the colors you want with high quality and deliver them to your address wherever you are in the world. In addition, we advertise your product by printing the company logos of our customers on the sticker and sticking them on the products. We guarantee that our prices will be the best you can find and the best service.

Request for a quote

GEOGAS LTD SKOPJE

North Macedonia

Mineral CO₂ is extracted from the natural sources owned by Geo Gas, which is processed and filtered to a quality of 99.98%, evaluated according to the highest European and world criteria.

Request for a quote

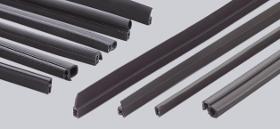

EMKA PROFILES LIMITED

United Kingdom

Rubber extrusions in EPDM , NBR, CR, Pvc Moulded into frames with or without steel insertion. Small MOQs, Delivery worldwide, Competitive prices Very High Quality.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

W. MÜLLER GMBH

Germany

Our extrusion heads for blow molding meet the highest demands in terms of precision, availability, performance and ease of use. And They ensure your safe and cost-efficient production.

Request for a quote

NOVELIS DEUTSCHLAND GMBH OHLER® - FLEXROHRE

Germany

There are many benefits of impact extrusion. Whether combined, forward or backward extrusion, there is a high level of dimensional accuracy and the possibility to achieve a close approximation to the final shape. Offering 100 percent tightness, impact aluminum extrusion allows a high degree of transformation in a single production step, high operating speeds at low unit costs and numerous shaping and design possibilities. In addition, impact extrusion provides compact structure, a smooth surface, no soldered or welded seams and excellent stability.

Request for a quote

PROMIX SOLUTIONS AG

Switzerland

Microcell foam extrusion systems from Promix are used for a wide variety of applications and for almost all polymers. Thanks to the production of very homogeneous microcellular foam structures, high-quality foam products with very low densities and excellent mechanical properties can be produced. Physical foaming can reduce material consumption and thus costs by an average of 20%. This not only saves money but also has a positive impact on the environment. Promix Foam extrusion systems set standards in the production of microcellular foam products with very homogeneous cell structure and high process consistency. The systems operate with environmentally friendly blowing fluids nitrogen or CO2 and are easy to integrate into existing or new extrusion lines. Depending on the application, density reductions of 5 to over 70 % can be achieved.The technology can be used for packaging films, sheets, foam core and corrugated pipes as wellas profiles, cable sheating, blow molds and blown films.

Request for a quote

PROMIX SOLUTIONS AG

Switzerland

Insufficient surface quality, long cooling times, uneven thickness tolerances or other quality problems often limit maximum production output. Promix melt blenders eliminate these limitations sustainably and lead to significant cost savings. Would you like to optimize your extrusion process? Improved melt homogeneity and a more uniform melt temperature create tighter thickness tolerances and better surface quality. And quite often, it can also increase production throughput. Promix offers you highly effective static mixers and melt blenders at low investment costs. They are supplied ready for installation, including heater bands and holes for pressure and temperature sensors. The melt blenders are usually installed downstream of the screen changer & gear pump, and upstream of the die. The very short installation length allows easy retrofitting in existing extrusion lines.

Request for a quote

INDUSTRIAL BRUSHWARE LIMITED T/A IBEX INDUSTRIAL BRUSHES

United Kingdom

Aluminium extruded holder is available to suit 5mm 8mm & 10mm brush strip. It is available in 45 degrees, 90 degrees, and 180degrees to suit the brush strips application. Other types of holder are available on request. Bespoke products are also availablefor high end finishes and requirements. Call us to discuss your needs. Our professional & expert staff will always be able to help wherever possible.

Request for a quote

JUNTA POLYMERS

Belgium

Rubber and Silicone extrusion following your samples or technical drawing in EPDM, Silicone or other qualities.

Request for a quote

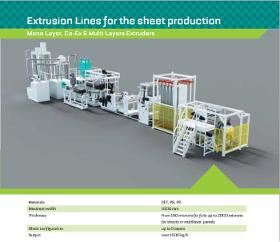

KUZEY GLOBAL

Turkey

Extrusion lines for thermoforming plastic products

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

Ming Xiao Manufacturing Co Ltd is specialize in Plastic extrusion profiles,pipes, rods, rails, LED lampshade,Wiring trunking, Speaker body, Kinds of Shells and slides,we can produce plastic extrudsion products from materials of PVC, ABS, PP,PE,PC,PMMA, AS /PE,TPE/TPR... The extrusion molding service is to heat the plastic material and make it in the state of viscous flow. Under the action of pressure, the plastic mold is used to form a continuum that is similar to the shape of the die. Then the cooling is made to form a glass state, and the plastic products with a certain geometry and size are obtained by cutting. The Plastic Extrusion profiles widely use for auto parts, light rail train fittings, lamps and lanterns, refrigeration industry, household electrical appliances, stationery, warehousing and other enterprises to provide quality support services. If you need any plastic extrusion profiles,welcome send your drawings and samples to us for a quote.

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

Ming Xiao produce extrusion TPR / TPE / PU / TPU soft profiles. TPR is a thermoplastic rubber material, which is generally modified with SBS base material (in a narrow sense, this is a way to distinguish it from SEBS modified TPE), and is usually made into spherical particles, ellipsoidal particles and round strips. Glossy transparent or white particles. TPR material has the characteristics of rubber, with good elasticity, resilience and shrinkage, abrasion resistance and weather resistance. However, the processing method is simpler than that of rubber. It can be processed and produced by an ordinary injection molding machine. It can also be used for plastic toughening modification. It can be encapsulated or composite injection molded with PP, ABS and other materials. It does not need to be vulcanized like rubber. ,Increase productivity. In addition, TPR is a new type of environmentally friendly material, non-toxic, tasteless, and recyclable, which is a huge advantage over rubber.

Request for a quote

LOUISON INDUSTRIES

France

Discover coextruded tape, used in the building and public works and agriculture sectors as reinforcement in a construction operation (e.g. reinforced earth, tutoring...). A combination of textile and plastic, coextrusion is a process that involves melting thermoplastic resins which then cover the textile in the form of threads (high-tenacity polyester threads, for example). Each material brings its own properties to the product. So, according to the specifications we receive, we will incorporate all the characteristics you need: resistance, texture, etc... Note: the plastic residues generated can be transformed into reusable beads, reducing the overall waste produced during the extrusion process.

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

Ming Xiao Manufacturing Co Ltd is specialize in Plastic extrusion profiles,pipes, rods, rails, LED lampshade,Wiring trunking, Speaker body, Kinds of Shells and slides,we can produce plastic extrudsion products from materials of PVC, ABS, PP,PE,PC,TPE/TPR, AS /PE... The extrusion molding service is to heat the plastic material and make it in the state of viscous flow. Under the action of pressure, the plastic mold is used to form a continuum that is similar to the shape of the die. Then the cooling is made to form a glass state, and the plastic products with a certain geometry and size are obtained by cutting. The Plastic Extrusion profiles widely use for auto parts, light rail train fittings, lamps and lanterns, refrigeration industry, household electrical appliances, stationery, warehousing and other enterprises to provide quality support services. If you need any plastic extrusion profiles,welcome send your drawings and samples to us for a quote.

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

Custom Tansparent PC Pipes & PVC Profiles, High transparency, light transmittance up to 92%. Ming Xiao Manufacturing Co Ltd is specialize in Plastic extrusion pipes, rods, rails, LED lampshade,Wiring trunking, Speaker body, Kinds of Shells and slides from PVC resins. The extrusion molding service is to heat the plastic material and make it in the state of viscous flow. Under the action of pressure, the plastic mold is used to form a continuum that is similar to the shape of the die. Then the cooling is made to form a glass state, and the plastic products with a certain geometry and size are obtained by cutting. The Plastic Extrusion profiles widely use for auto parts, light rail train fittings, lamps and lanterns, refrigeration industry, household electrical appliances, stationery, warehousing and other enterprises to provide quality support services. If you need any plastic PC extrusion pipes or profiles,welcome send your drawings and samples to us for a quote.

Request for a quoteResults for

Extrusion - Import exportNumber of results

247 ProductsCountries

- Turkey (69)

- Germany (52)

- China (36)

- United Kingdom (24)

- Belgium (14)

- Netherlands (10)

- Taiwan R.O.C. (8)

- Switzerland (7)

- France (6)

- United States (4)

- Italy (3)

- Austria (2)

- Hong Kong (2)

- Romania (2)

- Bulgaria (1)

- Czech Rep. (1)

- Greece (1)

- Lithuania (1)

- North Macedonia (1)

- Poland (1)

- Russia (1)

- Spain (1)

Category

- Extrusion of rubber and plastic (51)

- Extrusion, plastics - machinery (40)

- Extrusion - steel and metals (20)

- Control boxes - electric (17)

- Aluminium and aluminium alloys (12)

- Aluminium alloys (8)

- Steels and metals - machining (7)

- Aluminium wires and cables (5)

- Electric motors and parts (4)

- Gear pumps (4)

- Pneumatic system components (4)

- Applicators for adhesives and glues (3)

- Films and sheets, plastic (3)

- Foundries, aluminium (3)

- Hoses, pipes and tubes - plastic (3)

- Pipes and tubes, aluminium (3)

- Rubber products (3)

- Solar energy (3)

- Steel & Metals (3)

- Bars - non-ferrous metal (2)