- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- flowmeters

Results for

Flowmeters - Import export

APT ANGEWANDTE PROZESSORTECHNIK GMBH

Germany

Different flow ranges possible - Overpressure and underpressure possible - Two measuring ranges possible in one device

Request for a quote

APT ANGEWANDTE PROZESSORTECHNIK GMBH

Germany

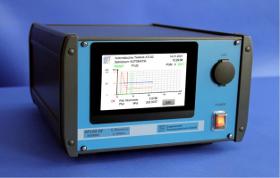

Overpressure and vacuum possible - Different pressure and flow ranges possible - Several measuring ranges possible in one device - Modern operation via 5" touch graphic colour display - Completely remote controllable, optionally via ProfiNet

Request for a quote

KROHNE MESSTECHNIK GMBH

Germany

The OPTISONIC 6300 P is a portable, battery-powered ultrasonic clamp-on flowmeter for temporary flow measurement of (non-)conductive liquids. It can be used at virtually any location and without process interruption or need to cut pipes. Due to its flexibility, the meter is equally suited for comparative measurements on stationary measuring equipment (e.g. pumps, flowmeters etc.) or for use as a short-term replacement of faulty devices. The OPTISONIC 6300 P consists of a combination of one or two clamp-on sensors and one handheld electronic signal converter. The robust clamp-on rail can be easily attached to almost any pipe up to DN1500/160". The readings of the meter are shown on the handheld LCD and are stored in the integrated memory for data logging. In addition, all readings can be transferred to a PC via the included USB stick in order to further analyse or store the data.

Request for a quote

KROHNE MESSTECHNIK GMBH

Germany

Ultrasonic gas flowmeter The OPTISONIC 7300 offers an ultrasonic measurement system dedicated for process gas flow applications. The OPTISONIC 7300 does not have the limitations that are usually associated with traditional gas flow meters like periodical recalibrations, maintenance, pressure loss and a limited flow range. The OPTISONIC 7300 combines the advantages of ultrasonic measurement in a way that it is efficient, reliable and easy to use.

Request for a quote

KROHNE MESSTECHNIK GMBH

Germany

Sensor for bulk mass flow Whilst the OPTIMASS 2000 has been developed to meet the demanding custody transfer requirements of the Oil & Gas industry, it is well suited to bulk measurement in many applications. The option of Super Duplex (UNS S32750) provides a maximum operating pressure of 180 barg / 2610 psig. The newly launched OPTIMASS 2000 S400 meter with the innovative four straight tube design is with a max. flowrate of 4 600 t/h / 169 000 lb/min the highest capacity Coriolis mass flowmeter in the world. OPTIMASS 2400 with EGM™ (Entrained Gas Management): the meter maintains operation over a wide range of gas fractions and complex flow conditions.

Request for a quote

KROHNE MESSTECHNIK GMBH

Germany

The solution for low flow measurement The OPTIMASS 3000 is the cost effective solution for accurate measurement in a variety of applications, where there is a low process flow. Combined with the power of the MFC 400, the OPTIMASS 3000 will provide accurate measurement of mass, volume, density and concentration. OPTIMASS 3400: EGM™ Entrained Gas Management allows continuous measurement with 0 to 100 % gas entrainment - Large diameter for bulk measurement - Stainless steel measuring tubes (NACE compliant) - Super Duplex option offering a maximum operating pressure of 180 barg / 2610 psig - Custody transfer of liquids and gases according to MID & OIML and API & AGA compliant

Request for a quote

KROHNE MESSTECHNIK GMBH

Germany

Electromagnetic flow sensor in sandwich version The OPTIFLUX 1000 electromagnetic flow sensor is the economic and ecological solution for various industries, ranging from agriculture to utilities and from fire fighting to machinery. The instrument is economical due to low investment and maintenance costs; it is ecological due to accurate measurements and no waste. - Basic and fully functional flow sensor - Excellent price performance ratio - Quick and easy to install and operate

Request for a quote

KROHNE MESSTECHNIK GMBH

Germany

Solution for the water and wastewater industry The OPTIFLUX 2000 electromagnetic flow sensor is the optimum solution for water and wastewater applications. Its long-term reliability and durability make it the standard flow sensor for the water industry for measuring abstraction water, drinking water, wastewater, sewage and effluent. - Engineered and manufactured for the water and wastewater industry - Wide range of approvals for potable water - Long-term reliability and negligible maintenance

Request for a quote

KROHNE MESSTECHNIK GMBH

Germany

The OPTIMASS 6000 is a Coriolis mass flow sensor. Combined with the MFC 400 signal converter it forms the OPTIMASS 6400 high performance Coriolis mass flowmeter for all process applications including cryogenic or high temperature media as well as high pressure fluids.

Request for a quote

KROHNE MESSTECHNIK GMBH

Germany

The all-round solution for process industries The OPTIFLUX 4000 has a field proven and unsurpassed lifetime. This is assured by the fully welded construction, full bore pipe construction, absence of moving parts and wear resistant liner materials. Even for demanding applications in harsh environments or with aggressive and abrasive media KROHNE’s OPTIFLUX 4000 can offer a solution. Examples include water injection under high pressures (2500lbs), subsea installations, slurries with very high solids contents, alkaline solutions and acids, up to chemical dosing, bleaching, coloring, and black liquor in the paper industry. If required, a solution beyond our standard scope can be engineered. KROHNE has in house specialized know how on constructions, welding and exotic materials

Request for a quote

KROHNE MESSTECHNIK GMBH

Germany

Electromagnetic flowmeter in sandwich and flange version The OPTIFLUX 5000 is one of the most accurate flowmeters available in the market today. This is the result of a special tube design with conical parts, optimizing the flow profile. Leading metrological institutes use the OPTIFLUX 5000 as their master meter. - Exceptional long-term stability and accuracy - For highly aggressive and abrasive fluids - Fully vacuum-resistant with high-tech ceramics liner

Request for a quote

KROHNE MESSTECHNIK GMBH

Germany

The all-in-one solution Already the basic version of the OPTISWIRL 4200 is equipped with a temperature compensation for saturated steam applications. With the optional pressure sensor the OPTISWIRL 4200 has an integrated density compensation available, which even allows an exact measurement of gases and superheated steam with varying process conditions. The additional integrated gross and net heat measurement makes the OPTISWIRL 4200 to be a reliable partner for advanced energy management systems. The OPTISWIRL 4200 was designed for the safety-related applications from the very beginning. It was developed according to the standard IEC 61508 edition 2. The certification is effected within the scope of a Full Assessment by TÜV Süd. Thereby the OPTISWIRL 4200 can be used for continuous volume flow measurement in safety-related applications with classification SIL2.

Request for a quote

KROHNE MESSTECHNIK GMBH

Germany

The BATCHFLUX 3100 is an electromagnetic flowmeter (EMF) for rotary or linear filling machines. It is the economical solution for filling applications with conductive liquids.Due to its unique ceramic measuring tube, the mag meter features good repeatability and long-term stability. The flowmeter has an ultra-compact lightweight housing ideal for the tight spaces in volumetric filling machines. It can be used for filling of water or carbonised drinks. The EMF is suitable for common CIP cleaning procedures.

Request for a quote

KROHNE MESSTECHNIK GMBH

Germany

Ultrasonic flowmeter for high temperature gas and steam As the OPTISONIC 8300 provides a large measurement range and does not require recalibration, the installation can be simplified and costs reduced. For example since the flow sensor does not need to be removed, shut off valves and a bypass are not required. Also thanks to the large measurement range, a dual range measurement setup is not required. Traditional steam measurement solutions need continuous attention and recalibration to guarantee proper operation. As the diagnostics of the OPTISONIC 8300 enables it to look after itself, it does not require any attention. Even periodically recalibration is not required since the OPTISONIC 8300 provides excellent long term stability. Periodical verification of the proper functioning of the device can easily be done using the diagnostics as required.

Request for a quote

KROHNE MESSTECHNIK GMBH

Germany

The H250 M40 is the standard variable area (VA) flowmeter for the process and OEM industry. The VA meter combines mechanical flow measurement of liquids or gases with state-of-the-art communication capabilities. Additional electronic modules can be added or replaced at any time without process interruption. The H250 M40 is available in various materials and in many different versions. The sturdy all-metal flowmeter can be also used in applications with high pressures (up to 1000 barg / 14500 psig), temperatures (-196...+400°C / -320...+752°F) or aggressive media. It even allows installation in horizontal or fall pipes up to DN150 / 6". A special version for use in hygienic applications is also available. The H250 M40 is intrinsically safe and explosion-proof. Certain variants of the flowmeter with limit switch or analogue output are suitable for use in Safety Instrumented Systems (SIS).

Request for a quote

KROHNE MESSTECHNIK GMBH

Germany

Small flowmeters (metal) The DK 37 variable area flowmeters can either be equipped with a mechanical or electronic indicator and are suitable for measuring gases and liquids. They are sturdy, versatile all-metal measuring devices. All devices are fitted with a metering valve to accurately set the flow value. PPS housing as standard, stainless steel housing as option.

Request for a quote

KROHNE MESSTECHNIK GMBH

Germany

Small flowmeters (glass) The DK 46, DK 47, DK 48 and DK 800 variable area flowmeters feature glass cones of varying lengths for different accuracy requirements.The medium is visible and the flow value of the gas or liquid can be read directly off the scale at the height of the float. It is easy to change the measuring glass, which is protected by a plastic cover, without disassembling the fitting. For precise setting of the flow value, all devices are equipped with a metering valve.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

EP EHRLER PRÜFTECHNIK ENGINEERING GMBH

Germany

We offer you standardized complete systems for the measurement of volume & mass flows. We use measuring elements that have established themselves within previously built customer-specific test benches and convince with high measuring accuracy. The SMF® series of nozzle test benches has been specially developed for calibration with air. Critical nozzles are used as measuring elements. Up to 18 critical nozzles can be combined, depending on customer requirements. EP offers different designs for the register: Drum Design, Block Design & Register Design. Another variant is a mobile system: The EP SMF® - Mobile Flow Calibrator - a compact measuring system for flow calibration. EP Ehrler Prüftechnik manufactures single nozzles in the flow rate range from 0.005 to 2000 m³/h. In addition to our standard range, we also manufacture customer-specific nozzles that are perfectly designed for your application in compliance with DIN EN ISO 9300*.

Request for a quote

EP EHRLER PRÜFTECHNIK ENGINEERING GMBH

Germany

We develop and manufacture Venturi tubes and nozzles as individual components or as complete VMF® systems. The VenturiMasterFlow® measuring system, VMF® for short, is used for the precise measurement of air or gas volume and mass flows 100,000 m³/h The flow measurement by means of a Venturi tube or Venturi nozzle is characterized by high measuring accuracies up to 0.5% MW and a fast response time < 10 ms. A further benefit is the high long-term stability of the measuring element.

Request for a quote

CETA TESTSYSTEME GMBH

Germany

The flow tester CETATEST 915 is used for flow testing with compressed air. It includes a measuring system consisting of laminar flow element (LFE) and differential pressure sensor In the direct test method the air, provided by the internal pressure regulator, flows through the measuring section before it enters the test part.In the indirect method, the measuring section is located in the outlet flow of the test part. Due to the special design of the measuring section a laminar ow is generated. The resulting pressure difference is directly proportional to the volume flow. With the optional electronic pressure regulator and four calibrations for up to four test pressures the application range is substantially expanded. Special versions: The CETATEST 915-G is a fully automatic flowmeter for the detection of leaking parts. Typical applications: 915: Testing of valves, vehicle exhaust systems, pipes, membranes, 915 G: Gas appliance industry, after-work jobs in the automotive industry

Request for a quote

RIEGLER & CO.KG

Germany

Various measurement devices of differing shapes are combined under the term Analysis Equipment. The leak testing device in its various designs and the flowmeters are supplemented by a hand-held measurement unit for industrial applications. A specially tuned analysis package (software package) is available for the differential pressure flowmeter.

Request for a quote

KROHNE MESSTECHNIK GMBH

Germany

The VA 40 variable area flowmeters are suitable for measuring liquids and gases The standardized device design is available with various connections that conform to standards. The glass measuring cone, protected by a metal sleeve with a viewing glass, makes it easy to read the flow directly and observe the medium. The suitability for measuring the flow of gases in accordance with the DVGW G260 process sheet has been certified by the DVGW testing station at the Gas-Fired Thermal Institute in Essen.

Request for a quote

BOPP & REUTHER MESSTECHNIK GMBH

Germany

Mass flow meters serve to measure fluids and gases. The mass flow meter utilises the Coriolis force for flow measurement. The omega loop has proven itself particularly suitable for this process. The measuring tubes, which are bent to omega loops, are completed by two measuring bars and vertically secured torsion bars to create a harmonious oscillator. This carefully balanced and robust design has an extremely low power input. The frequency of the system essentially depends on the mass of the bars and the elasticity module of the torsion bars. Two electromagnetic coils set the system in motion. As soon as liquid or gas flows through the oscillating omega tubes, the resultant Coriolis force causes displacement of the tubes. The comparative relationship is established and the change in displacement is proportional to the mass flow. Application • i.a. custody transfer for mineral oils, bitumen and other viscous media

Request for a quote

BOPP & REUTHER MESSTECHNIK GMBH

Germany

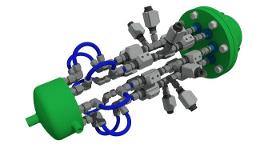

Modular dosing system for filling conductive liquids in packaging machinery. Advantages over mechanical systems • no moving mechanical parts • easy cleaning in comparison with piston fillers • easy adjustment of batch quantities • no mechanical forces are applied to the product Special features • short dosing times of up to 100 ms possible • filling quantities from 1ml to DN 10 • small dimensions of the transmitter • wide range of batch quantity with one nominal size • CIP / SIP ability up to 140°C • min. conductivity >1µS/cm • complete system Flexibility • DN 10, 15, 20, 25, 32, 40 • various connections are available e.g.: • aseptic connection according to DIN 11864-1 to 3 • TRI-CLAMP according to DIN 32676 • milk thread according to DIN 11851 • 3A approved MDS completely electronic • different housing for 6/12/18 measuring channels • software for Linear, Rotary and Single Start Machines • connection to operator terminal or PLC • direct control of the dosing valve • 24 VDC...

Request for a quote

HEIFEI COMATE INTELLIGENT SENSOR CO., LTD

Germany

TGF600 Screw-in thermal mass flowmeters for small pipe size gas meausred Inline type can be installed/removed without stopping the line Minimum flow rate down to 0.3m/s, 1:100 super wide turndown ratio No moving part, almost no pressure loss Direct mass flow measurement, do not require temperature or pressure compensation TGF600 Series screw-in inline thermal mass flowmeters measures the gas mass flow base on thermal dispersion theory. It combines COMATE’s advanced technology on transmitter, sensor, filming and calibration, can provide stable and accurate measurement even under harsh industrial applications and require very less maintaining.

Request for a quote

HEIFEI COMATE INTELLIGENT SENSOR CO., LTD

Germany

Steam Flow Meters|Vortex Mass Flow Meters, which provides with the excellent signal processing capability and enhance the vortex metering technology to a new level, which means it has lower measuring limit, better stability and accuracy. The special signal processing method has also ensured a better anti-vibration by eliminating the vibration signals.

Request for a quote

HEIFEI COMATE INTELLIGENT SENSOR CO., LTD

Germany

VFM60MV multivariable vortex flowmeters is an integral solution for mass flow /standard flow measurement of steam and gas. Integrated pressure and temperature sensors for density compensation, so it can also measure temperature, pressure, density, mass flow and standard flow. User would only need one flowmeter to measure and read all this parameters, this advantage leads to lower cost and maintaining.

Request for a quoteResults for

Flowmeters - Import exportNumber of results

29 ProductsCountries

Company type