- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- ultrasonic measuring equipment

Results for

Ultrasonic measuring equipment - Import export

KROHNE MESSTECHNIK GMBH

Germany

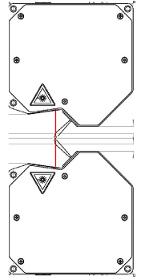

The ALTOSONIC V12 is a 12-chord ultrasonic custody transfer (CT) flowmeter for natural gas. It has been designed to offer the best possible measurement accuracy, not only during calibration under ideal conditions but also during less ideal conditions in the field. As a result, ALTOSONIC V12 is the first ultrasonic flowmeter that was certified to OIML R137 class 0.5 by NMi. Due to its design with 12 acoustic chords a flow conditioner is no longer required; standards such as AGA9, ISO 17089 and MID are met with just 5D straight inlet piping. CBM flowmeter diagnostics are standard and give an exact picture of what is happening inside the flowmeter. With the optional KROHNE Care diagnostic expert system an integrated web server becomes available that presents the results as an easy to access webpage – in plain language.

Request for a quote

SONIKKS® ULTRASONICS TECHNOLOGY GMBH

Germany

Defined frequency between 20 kHz and 100 kHz

Request for a quote

SONIKKS® ULTRASONICS TECHNOLOGY GMBH

Germany

Our external controller is used to connect to generators that do not have an implemented control display. It is especially useful when the generator configuration rarely needs to be changed. A control panel allows the adjustment of several generators (one after the other).

Request for a quote

SONIKKS® ULTRASONICS TECHNOLOGY GMBH

Germany

The external front is intended to connect to generators which do not have an integrated display. It is best suited to adjust generators that are difficult to reach. Therefore, the external front is mounted separately from the generator. Its compact design makes it much easier to accommodate than a generator. The external front is intended for use with just one generator.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

SONIKKS® ULTRASONICS TECHNOLOGY GMBH

Germany

Defined frequency between 20 kHz and 100 kHz

Request for a quote

SONIKKS® ULTRASONICS TECHNOLOGY GMBH

Germany

Defined frequency between 20 kHz and 100 kHz

Request for a quote

SONIKKS® ULTRASONICS TECHNOLOGY GMBH

Germany

Defined frequency between 20 kHz and 100 kHz

Request for a quote

SONIKKS® ULTRASONICS TECHNOLOGY GMBH

Germany

Integrated compressed air control for sonotrode/converter cooling Optimally suitable for the use of a handwelding gun Defined frequency between 30 kHz and 100 kHz

Request for a quote

QUELLTECH GMBH

Germany

Many materials cannot be measured tactilely, therefore non-contact thickness measurements become necessary. Especially e.g. with glowing materials, or wet processes, a continuous tactile measurement is nearly impossible. Furthermore, web speeds in plant engineering and production have increased, requiring a corresponding fast sampling rate of the measuring systems. In addition, high measuring widths are often required. Why is contact free measurement technology so perfect for this application? Can be used in any web width, Scalable measurement thicknesses from a few millimetres to several meters, Thickness and coating thickness can be measured for different materials, Vibrations of the web materials, can be compensated, Turnkey solution for mechanical engineering, Non-contact and non-destructive measurement method, Large distances to the measured object are possible, Measurement of free forms,

Request for a quote

QUELLTECH GMBH

Germany

The QuellTech laser sensor family Q4 or Q5 used for these tasks is generally mounted on an arm of a rotational axis, to scan along the complete 360° angle of the internal surface in a sequence of strips. The Q4 sensors can also be used to control the weld seam tracking itself for rapid setup and ease of use. Even during a project, the range and scope of the Q Series sensor demonstrates the advantages of a modular system to quickly adapt to project needs, where the smallest system has provided fast analysis of pipes as small as 105mm. The low power, with standard communication protocols, enable battery powered systems to transmit wireless data to other systems for review and cloud back up.

Request for a quote

MICRO-EPSILON

Germany

The high-performance optoNCDT ILR2250 laser distance sensor is used whenever large measuring ranges and high accuracy are required. The optoNCDT ILR2250 can be installed at distances up to 100 m, and even up to 150 m with a reflector film. This sensor impresses when measuring dark, structured and poorly reflecting surfaces, while providing stable measurement results to millimeter accuracy. The optoNCDT ILR2250 laser distance sensor is used in transportation, logistics and conveyance technologies as well as automation and the metals industry. This is where the sensor enables reliable measurement results even when it is, e.g., installed at a safe distance from heat emitting measuring objects. In addition, difficult-to-access places via mirrors or through glass sheets can be detected.

Request for a quote

WALTER UHL TECHNISCHE MIKROSKOPIE GMBH & CO. KG

Germany

The measuring wire ist fastened to the headstock or a special holding device, fed at the end of the base over a pulley and stretched tight with a weight (layout according to DIN 8606). The alignment tester must be placed on the carriage of the machine or a corresponding device, which can be moved in a longitudinal direction in predefined steps on the machine base. The measuring wire must be aligned in such a way that the same values are measured in the starting and end position of the carriage, i.e. that it is tensioned to form an imaginary connecting line parallel to these positions. When the wire is aligned to the bearing, the value display is set to zero. The straightness deviation can now be read directly on the display for each position when both parts of the image are fitted together by moving the microscope horizontally with the integrated micrometer spindle.

Request for a quoteResults for

Ultrasonic measuring equipment - Import exportNumber of results

16 ProductsCountries

Company type