- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- industry

Results for

Industry - Import export

THOMAS CONSTRUCTIONS MECANIQUES - TCM SAS

France

As a result of the geographical location of TCM - THOMAS CONSTRUCTIONS MECANIQUES in the heart of the Vosges, the paper industry is also one of the four historical sectors of activity that have driven our growth. We work closely with the main paper mills in the region which, despite the increasing global nature of their business, have still shown us unfailing loyalty. Beyond special machinery, this collaborative work has helped us to develop specialist expertise in : the upgrading of existing production plants to reduce set-up and adjustment times and increase productivity conveyor systems and roller elevators Applications and projects : conveyor systems roller elevators special packaging and wrapping machines the upgrading of existing paper mills to reduce set-up and adjustment times and increase productivity Related operations on customers’ sites : maintenance of equipment and infrastructure repairs

Request for a quote

THOMAS CONSTRUCTIONS MECANIQUES - TCM SAS

France

As a result of the geographical location of TCM - THOMAS CONSTRUCTIONS MECANIQUES in the heart of the Vosges, the agri-food industry is one of the four historical sectors of activity that have driven our growth. Among other organisations, we work with the main industrial cheese dairies in the region, which have shown us unfailing loyalty. Beyond special machinery, this collaborative work has helped us to develop specialist expertise in : the use and machining of stainless steel dosing systems for viscous foodstuffs food elevators Applications and projects : conveyor systems stacking systems food elevators process piping robotic units special packaging and wrapping machines dosing workstations cleaning systems control cabinets with PLC Related operations on customers’ sites : maintenance of equipment and infrastructure repairs technical upgrading of existing equipment Safety compliance of existing equipment

Request for a quote

THOMAS CONSTRUCTIONS MECANIQUES - TCM SAS

France

Trust in our experience and expertise to upgrade your existing industrial equipment in order to make it more technical and efficient and ensure its compliance. Our specialised teams will take care of : the technical upgrading and modernisation of your existing equipment in order to reduce your set-up times and/or increase productivity, as well as extending its operating life. the assurance that your facilities are compliant with the latest legal requirements in terms of safety/regulations. These operations can be carried out with the support of your maintenance teams or independently by our teams. We should specify that our teams have all the necessary clearances and qualifications, the insurance coverage for this type of work, and are highly experienced in on-site operations. Upgrade and retrofit operations are necessary to make significant productivity and operating gains, offering a particularly good return on your investment.

Request for a quote

FORKLIFT ENERGIE

France

Retrofit of your GSE thermal equipment to electric and changeover of equipment fitted with lead batteries to LITHIUM technology. FORKLIFT ENERGIE puts its 15 years of industrial experience at your service, whether you need to re-motorise thermal runway equipment in electric mode, study a battery pack adapted to your heavy or light electric vehicle or advise you on the choice of an industrial lithium battery compatible with the activity of your work vessel or naval leisure craft. Design and integration of battery energy storage systems, Support in choosing solutions that take into account the human, technological, functional, sustainable and financial aspects. At every stage, we draw your attention to the advantages and disadvantages of the proposed technology

Request for a quote

SDT ULTRASOUND SOLUTIONS

Belgium

CONMONSense delivers precise, repeatable data about the health of your assets and electrical systems also in the most challenging environment. Its resonant piezo element is optimized for ultrasound driven lubrication, mechanical fault detection, and monitoring the health of valves, steam, hydraulic systems and electrical defects. Ultrasound is a true measure of the FITness of your facility. Most assets produce FRICTION, IMPACTING, and TURBULENCE as defect indicators. CONMONSense hears these phenomena at their inception and delivers an analog signal response to your connected measurement system. With an output range from 4-20mA or from 0-10V, CONMONSense mounts permanently to any asset to provide continuous condition monitoring data. Avoid unplanned downtime and put the safety of your plant and colleagues first.

Request for a quote

PLUGTITE

Belgium

For use in operations such as Electrostatic lines, die casting etc. where restistance to hightemperatures is required. Small (2mm - 14mm) Medium (5mm - 24mm) Large (15mm - 45mm) Greater resistance to most oils and chemicals Can be used in situations up to 230°C (445°F) Does not shrink, leak or discolor Resistant to sunlight for greater shelf life Does not split/crack or deteriorate Easy to use. Insert, squeeze, press home and release The compressed rubber ensures a tight fit

PLUGTITE

Belgium

This plug is specifically produced for use in the food and beverage processing industry. The use of the plugs helps to ensure that sensitive working areas are kept free of contamination from oils and other fluids by preventing leakage when cleaning and servicing machinery and equipment Small (2mm - 14mm) Medium (5mm - 24mm) Large (15mm - 45mm) Greater resistance to most oils and chemicals Temperature range from -25°C up to 90°C Does not shrink, leak or discolor Resistant to sunlight for greater shelf life Does not split/crack or deteriorate Easy to use. Insert, squeeze, press home and release The compressed rubber ensures a tight fit

PLUGTITE

Belgium

Helps prevent the leakage and contamination of various fluids, including hydraulics, and chemicals, during the service, maintenance, and storage of machinery and equipment. Small (2mm - 14mm) Medium (5mm - 24mm) Large (15mm - 45mm) Resistance to most oils and chemicals Temperature range from -25°C up to 90°C Does not shrink, leak or discolor Resistant to sunlight for greater shelf life Does not split/crack or deteriorate Easy to use. Insert, squeeze, press home and release The compressed rubber ensures a tight fit

LABOREX

Belgium

Spray washing: automatic cleaning For companies, manual cleaning of parts is a time-consuming activity. The Laborex spray washing machines ensure the automatic cleaning, rinsing, degreasing and drying of industrial parts made of metal or plastic. This way you can carry out other work without any worries while your parts are automatically cleaned. Test our rotating spray washing machines yourself We would like to invite you to come and test our rotating spray washing machines in our showroom. This is completely free and without obligation. Make your appointment now. Ideal solution for external cleaning of parts The Laborex rotating spray washing machines are the ideal solution for the external cleaning of parts. The spray washing principle is simple: you place the parts to be cleaned in the basket and select a washing program.

Request for a quote

LABOREX

Belgium

Trains, trams and buses cover many and great distances every day. This leaves traces and causes a lot of damage and enormous contamination to the parts. Cleaning and removing grease, oil, brake dust, carbon and other hard deposits is therefore a must to keep trains, trams, buses and other rolling stock running smoothly every day. The Laborex Heavy-Duty Parts Washer configurations are suitable for all rail and transport parts. The Laborex Rail and Transport parts washing machines and cleaning systems guarantee that your parts are 100% clean, dry and protected against rust when they leave the machine. Cleaning solutions for train and transport parts with complex geometries Different shapes and sizes of train and transport parts and their complex geometries sometimes make cleaning difficult. For example, heavy grease deposits or hard-to-reach interior spaces must be cleaned. Another challenge is cleaning heavy weights up to several tons.

Request for a quote

FILTRATION SERVICES LTD

United Kingdom

Inspection contracts typically cover an inspection of the equipment at agreed intervals, followed by a detailed report stating any recommended maintenance, repairs or spares. Beyond the work covered by an inspection contract our service contracts cover the maintenance work, typically involving lubricant changes, replacement of wear plate and filter media.

Request for a quote

TAVENGINEERING

Italy

Our maintenance and repair service perfectly sums up customizable service plans, advanced technologies, and a timely and qualified support. Whether it be for technical assistance by phone or on-site assistance, we offer prompt and effective solutions for any problem around the world.

Request for a quote

TAVENGINEERING

Italy

As well as new installation we provide industrial machinery moving and relocation services. From the initial planning stage up to the final commissioning and start-up of the equipment, we guarantee worry-free relocation for any industrial equipment.

Request for a quote

TAVENGINEERING

Italy

Can you upgrade instead of buying new machinery and still get better performance? We have top experts that are well placed to provide a wide range of solutions for industrial equipment retrofit and refurbishment – for a furnace that stays as good as new!

Request for a quote

TAVENGINEERING

Italy

We strive for cost-efficient solutions, immediate response and the right part delivered on time. With thousands of spares in stock, we ensure that you won't experience any delays, thus saving time and money. Like all of our satisfied customers, you will be thrilled with our fast delivery.

Request for a quote

RIDZEWSKI GMBH

Germany

The automatic leakage tester used to control the tightness of CO2 inert gas packaging allows even the smallest leaks - even in the micro range - to be detected.The package is tested by simply placing it in the vacuum chamber. The automatic test cycle starts when the lid is closed. The unit generates a user-defined vacuum during this process. After the vacuum is reached, the sensor is set to the "virtual" zero point. If the CO2 concentration rises during the measuring time that now begins and was previously selected by the user, this indicates that the packaging is leaking. The measured increase of the CO2 content in ppm gives information about the size of the not tightly sealed area. The sensor demonstrably detects even the smallest leaks up to approx. 10 µm. (µm is a micrometre and corresponds to 0.001 millimetres)

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

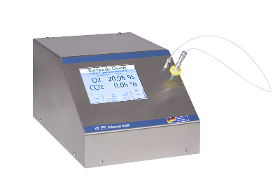

RIDZEWSKI GMBH

Germany

Our EPC 3GAS analyser is a more flexible variation of the basic model. The device changes the measurement automatically or externally controlled in order to monitor several processes simultaneously or consecutively. The change of the currently active measurement from process 1. to process 2. is done either by an external signal or in an adjustable time interval. Since our sensors can determine the oxygen concentration very quickly, time intervals of 30 seconds are realistically achievable. With desired concentrations of approx. 500 ppm, this is completely sufficient. Advantages - Over 20 years of experience in development and optimisation - Top response time and short heat-up phase - Two different sizes for added flexibility - Long average life components - Digital measurement data logging - User-friendly filter change - 5.7 inch touch screen - Intuitive menu navigation - in many languages

Request for a quote

RIDZEWSKI GMBH

Germany

The Zr-Ox EPC is our standard model for continuous monitoring of residual oxygen. Advantages - Over 20 years of experience in development and optimisation - Top response time and short heat-up phase - Two different sizes for added flexibility - Long average life components - Digital measurement data logging - User-friendly filter change - 5.7 inch touch screen - Intuitive menu navigation - in many languages - Various RS232 protocols that can be changed in the unit for communication with different soldering, packaging soldering, packaging machines, analysers or other equipment and processes - Operation for user and administrator in different levels - Standardised 0/2-5/10 VDC or 00/04-20 mA analogue signal adjustable - 3 backups for storing different unit functions and settings - Display of all alarms and errors

Request for a quote

RIDZEWSKI GMBH

Germany

The EPC Spot is our measuring device for a random check of the gas levels of O2/CO2 in packaging or packaging machines. A sample is taken by a special needle. Due to the small amount of gas the analyser needs for the measurement, blister packs or ampoules can also be tested. As a user, you can enter several limit values for different products in the device. The result is then additionally visualised in red or green. All measurements are stored in the device and can be further processed in various ways. Advantages - Over 20 years of experience in development and optimisation - Top response time and short heat-up phase - Two different sizes for added flexibility - Long average life components - Digital measurement data logging - User-friendly filter change - 5.7 inch touch screen - Intuitive menu navigation - in many languages

Request for a quote

RIDZEWSKI GMBH

Germany

The EPC SMC is equipped with an integrated proportional valve. This allows the analyser to automatically regulate the gassing in a wide range of processes. All settings for the control can be configured on the unit or via external signals. This means that the customer is not required to control the process completely manually. This gives you the option of controlling the gassing at our analyser or at the plant. For some processes, a single adjustment is sufficient and the production runs fully automatically from then on. Advantages - Over 20 years of experience in development and optimisation - Top response time and short heat-up phase - Two different sizes for added flexibility - Long average life components - Digital measurement data logging - User-friendly filter change - 5.7 inch touch screen - Intuitive menu navigation - in many languages

Request for a quote

"KERTEX ENERGIJA" UAB

Lithuania

Our company’s employees use equipment specifically designed for this purpose – the extractor – to carry out complex dismantling and installation operations of heat exchanger bundles on a daily basis with a sufficient level of quality and safety. It is important to note that the professionals at KERTEX Energija are certified by the extractor manufacturer Peinemann Equipment B. V.

Request for a quote

POWER LUBE CONTROL SRL

Belgium

Power Lube IT Management is a powerful software for managing alarms and faults related to remote lubrication control never before designed and intended for maintenance professionals. It is an instrument for fault diagnosis and preventive maintenance technology developed specifically for the application of Improve your maintenance process. Increase productivity, reduce malfunctions, reduce maintenance costs ... How can Power Lube IT Management really help you? Automation of lubrication and maintenance controls Efficient planning and management Rationalization and efficiency of lubrication Real-time machine lubrication anomalies recording Reporting of malfunctions, alarms etc. Standardization of lubrication controls ...

Request for a quote

POWER LUBE CONTROL SRL

Belgium

Power Lube Box Recorder is a gateway collecting and recording data sent remotely by Power Lube Sensors. Our Power Lube Box Recorder can record all data sent up to 100 Power Lube Sensor units. It allows you to connect LoRa wireless network to IP network via WiFi, Ethernet, 4G cellular. LoRa wireless allows users to send data and achieve extremely long ranges at low data rates. The Power Lube Box Recorder has pre-configured to use for different countries

Request for a quote

POWER LUBE CONTROL SRL

Belgium

The Power Lube Box Recorder (outdoor) provides for a solid out of the box experience for quick deployment in outdoor and harsh industrial environments. With its industrial grade components, it achieves a high standard of reliability. Power Lube Box Recorder is a gateway collecting and recording data sent remotely by Power Lube Sensors. Our Power Lube Box Recorder can record all data sent up to 100 Power Lube Sensor units. It allows you to connect LoRa wireless network to IP network via WiFi, Ethernet, 4G cellular. LoRa wireless allows users to send data and achieve extremely long ranges at low data rates. The Power Lube Box Recorder has pre-configured to use for different countries.

Request for a quote

POWER LUBE CONTROL SRL

Belgium

The patented Power Lube Sensor system can be installed on all lubrication points of the machine. It can be adapted to all kinds of oil and grease pumps installed upstream of the system (supplied via a central lubrication system or automatic lubricators or even gas system lubricator or manual pump, etc.). Description of the Power Lube Sensor ® Precise control and mastered alerts: The Power Lube Sensor Technology cleverly developed for data collection of up to 100 Power Lube Sensor units. Design and functional description: The Power Lube Sensor allows both to control the quantity / volume of lubricant as it passes through the electromechanical system and the remote transmission of alarms related to poor lubrication faults. It also controls the various alarms (battery level fault alarm, lubricant volume fault alarm, operating alarm, etc.) while adapting to all lubrication systems and industrial machine lubrication points system.

Request for a quote

UDT GROUP LLC

Azerbaijan

Cummins engine generator 175 KVa

Request for a quote

ROBINSONS FACILITIES SOLUTIONS

United Kingdom

We offer commercial boiler installation, repair and maintenance services in the Yorkshire area.

Request for a quoteResults for

Industry - Import exportNumber of results

29 ProductsCountries

Company type

Category