- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- transportation- bulk

Results for

Transportation- bulk - Import export

PARSMEGA MAKINA

Turkey

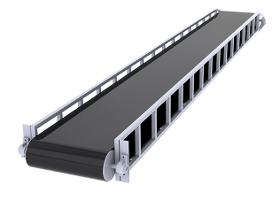

These are conveyors used for general transportation purposes, in the horizontal or inclined transmission of a wide variety of products to different distances. Material transportation in belt conveyors is provided by the belt stretched between the tension drum and the drive drum, which is moved by a motor-reducer system. Belt selection is made according to the type of product to be transported and types such as PVC, polyurethane, rubber and mesh belts can be selected. It is suitable for transporting boxed, bulk and packaged products. It is the conveyor type with the widest usage area, and its usage capacity is also highly variable. Conveyor leg group and chassis are made of Aluminum or electrostatic powder coated steel construction.

Request for a quote

INTERNORM KUNSTSTOFFTECHNIK GMBH

Germany

The screw elements can be mounted on a square shaft. You transport bulk materials into bins or silos via rotary movements.

Request for a quote

KEIPER GMBH & CO. KG ANTRIEBS- U. TRANSPORTTECHNIK

Germany

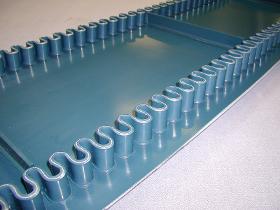

The Keiper UNITRANS conveyor belt series can be fitted with different sidewalls. Sidewalls are used as margin stops, usually together with cleats and entraining elements, in ascending and descending conveyor systems. The sidewalls prevent the products from falling off the sides of the belt. Inclined conveying: steep or angled conveying up to a slope of 80° in connection with cleats. Horizontal conveying: transporting bulk material and different-sized products. Conveyor belt sidewalls made of PVC, PU or special materials such as PU foam, polyolefin or polyester. With or without fabric interlayers. With or without foot. In the colors blue, white, green petrol, black or transparent. Depending on the design, in oil- and grease-resistant quality as well as FDA/EU approval. High abrasion and cutting resistance.

Request for a quote

EMPAC GMBH

Germany

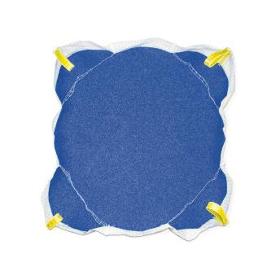

Flexible Intermediate Bulk Container (FIBC) of the product range Quintainer® offer and efficient way of utilization of room space and an excellent stability during transportation and storage of bulk goods. Forming diagonally and crossed placed cut-off walls increase the stability of Quintainer® considerably. The higher form stability in comparison to the conventional container for bulk goods ensures a better utilization of room space while transport and storage. Quintainer®-FIBC are available for various types of pallets. Fields of application: Packaging of fine-grained and flowable powder of the chemical industry and granules of the synthetic and food industry. Main industries: Products for the agriculture industry, construction industry, chemicals, pharmaceuticals, terrestrial and garden products, wood products and synthetic material, food, disposal of waste, cleaning agents

Request for a quote

BÜRKLE GMBH

Germany

If bulk goods are transported over long distances (in trucks, railway goods wagons), separation may occur. Taking the sample just from the surface therefore leads to the wrong result. Representative samples from all layers of the silo can be taken with the SiloDrill. The SiloDrill fits through all standard openings with its diameter of 90 mm.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

A twin bucket chain elevator can be described as a specially designed vertical conveyor system whereby it can transport bulk materials, such as grains, sand, ore, coal, and others that are granular or in powdered states. Consider this kind of elevator with two parallel chains or belts fitted with a series of buckets running in a continuous loop. In operation, the elevator scoops up material at the lower end with its buckets and transports it to the top for discharge. This mechanism ensures an effective and controlled way of moving large quantities of bulk materials vertically. These elevators find wide applications in industries where bulk material handling is a crucial aspect of the operation, like in agriculture, mining, construction, and manufacturing. This system comes into its own in applications that involve dependable, continuous material flow between various levels in a facility.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

What is a Twin Bucket Chain Elevator? A twin bucket chain elevator can be described as a specially designed vertical conveyor system whereby it can transport bulk materials, such as grains, sand, ore, coal, and others that are granular or in powdered states. Consider this kind of elevator with two parallel chains or belts fitted with a series of buckets running in a continuous loop. In operation, the elevator scoops up material at the lower end with its buckets and transports it to the top for discharge. This mechanism ensures an effective and controlled way of moving large quantities of bulk materials vertically. These elevators find wide applications in industries where bulk material handling is a crucial aspect of the operation, like in agriculture, mining, construction, and manufacturing. This system comes into its own in applications that involve dependable, continuous material flow between various levels in a facility.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

Ship loading and bulk material handling plants: what are they? Plants for handling bulk materials and loading ships are made to load different kinds of bulk materials onto ships quickly and safely. These materials may consist of fertilizers grains ores coal and other goods that are shipped in containers. Conveyor belts hoppers and loading spouts are examples of the specialized machinery used by ship loading plants to move bulk materials from processing or storage areas onto the ships. However a variety of bulk materials can be handled in industrial settings like mines power plants and manufacturing facilities by bulk material handling plants. These facilities store move and process bulk materials in huge quantities using conveyor systems stackers reclaimers and other equipment. The logistics and supply chain management of the industries involved in the transportation of bulk materials depend heavily on the smooth operation of ship loading and bulk material handling facilities.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

Ship loading and bulk material handling plants: what are they? Plants for handling bulk materials and loading ships are made to load different kinds of bulk materials onto ships quickly and safely. These materials may consist of fertilizers grains ores coal and other goods that are shipped in containers. Conveyor belts hoppers and loading spouts are examples of the specialized machinery used by ship loading plants to move bulk materials from processing or storage areas onto the ships. However a variety of bulk materials can be handled in industrial settings like mines power plants and manufacturing facilities by bulk material handling plants. These facilities store move and process bulk materials in huge quantities using conveyor systems stackers reclaimers and other equipment. The logistics and supply chain management of the industries involved in the transportation of bulk materials depend heavily on the smooth operation of ship loading and bulk material handling facilities.

Request for a quote

KMC GLOBAL EUROPE SP. Z O. O.

Poland

The ultimate solution for easy cleaning and maintenance. The Helix® Flexible Screw Conveyor is a versatile and reliable solution for all your material handling needs. Whether you need to transport powders, granules, or other bulk materials, the Helix® has got you covered. And with its easy disassembly and customizable options, it’s the perfect choice for industries such as food processing, pharmaceuticals, chemicals, and more. Our helicoid screw rotates within a fixed tube, ensuring efficient material conveyance from point A to B. With its exclusive T-handles couplings, you can disassemble this conveyor in just minutes for easy cleaning and minimal downtime. Plus, with a multitude of customizations available, the Helix® can adapt perfectly to your unique requirements.

Request for a quote

STIF EASTERN EUROPE

Ukraine

Stif EE provides performance calculation services for bucket elevators used in handling and transporting bulk materials. With many years of experience, we develop solutions that help achieve the desired productivity while ensuring the reliability and efficiency of your production process. The calculation process begins with gathering technical information using a survey sheet, where the client specifies key parameters such as product type, required capacity, belt speed, pulley diameter, and elevator height. We assist in optimizing these parameters to reach the necessary productivity while also offering solutions that reduce the material consumption of the elevator, ensuring cost-effective and efficient operation. Our calculations guarantee a high level of efficiency and stability in the transportation of bulk materials,with the unique characteristics of the product and working conditions. We offer innovative approaches that help reduce equipment costs while increasing productivity.

Request for a quote

STIF EASTERN EUROPE

Ukraine

The elevator bucket is designed for efficient transport of bulk grain and other materials in agricultural and industrial sectors. Manufactured using advanced French technology, the bucket ensures optimal performance by utilizing its full volume, increasing productivity. The innovative design reduces energy consumption by 15% and significantly lowers the metal capacity of the elevator system. Made from non-toxic, food-grade materials, the bucket prevents product damage and offers high wear resistance, making it an ideal solution for bulk product handling.

Request for a quote

STIF EASTERN EUROPE

Ukraine

The elevator bucket is designed for efficient transport of bulk grain and other materials in agricultural and industrial sectors. Manufactured using advanced French technology, the bucket ensures optimal performance by utilizing its full volume, increasing productivity. The innovative design reduces energy consumption by 15% and significantly lowers the metal capacity of the elevator system. Made from non-toxic, food-grade materials, the bucket prevents product damage and offers high wear resistance, making it an ideal solution for bulk product handling.

Request for a quote

STIF EASTERN EUROPE

Ukraine

The elevator bucket is designed for efficient transport of bulk grain and other materials in agricultural and industrial sectors. Manufactured using advanced French technology, the bucket ensures optimal performance by utilizing its full volume, increasing productivity. The innovative design reduces energy consumption by 15% and significantly lowers the metal capacity of the elevator system. Made from non-toxic, food-grade materials, the bucket prevents product damage and offers high wear resistance, making it an ideal solution for bulk product handling.

Request for a quote

SICOM SPA CONTAINERS

Italy

Coils carrier is a highly customized unit. Collapsible version – suitable to optimize empty returns Open Top version – suitable to transport bulk products as well as coils

Request for a quote

RUF MASCHINENBAU GMBH & CO. KG

Germany

Based on a individual needs assessment we tailor-make briquetting solutions including peripheral devices. RUF- Charging hopper with screw conveyor for charging & transporting of bulk material as aluminium, steel, stainless steel, other metals, wood, other bulk materials.

Request for a quote

FRANCE FIL INTERNATIONAL

France

This container is suitable for transporting fragile products in bulk, and is ideal for PET preforms. Its contents can be safely poured directly into the hopper of a PET blow-moulding machine.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

COMERC SP. Z O.O.

Poland

Belt conveyors(also sometimes called conveyor belts) are widely used in industry (as part of various production lines), logistics (equipment for warehouses and sorting plants), construction, trade, etc. Belt conveyors are designed for horizontal transport of various bulk materials such as pellets, sawdust, wood dust, wood chips etc. They are used as devices for loading and unloading silos (just like other types of our conveyors such as chain conveyors). Depending on the requirements and purpose, belt conveyors could work with capacities from 25 m3/h to 250 m3/h. Belt conveyors consist of drive section, tension section and intermediate sections. The number of intermediate sections depends on its length. Conveyors are equipped with multi-layer conveyor belt, driven by drive section and moving on rollers. Conveyor housing is made of structural steel with Magnelis® coating. Width of conveyor depends on required capacity.

Request for a quote

COMERC SP. Z O.O.

Poland

Redler type chain conveyors are designed for horizontal and inclined (up to 60°) transport of bulk materials such as pellets, sawdust, wood dust, wood chips etc. They are used as devices for loading and unloading silos, hammer mills, pellet mills and simultaneously for combining separate sections of technological lines. The drive section is equipped as standard with NORD company gear motors, rotation monitoring sensors and inspection hatches with overflow sensors. Drive shaft, on which flywheel is installed, is mounted in high-quality self-aligning ball bearings (SKF or SNR) Thanks to its construction tensioning section ensures constant optimum chain tension. Intermediate sections have length of 2000 mm as standard, but if necessary, section with non-standard length can be made. Bottom of conveyor is lined with antistatic, wear-resistant material (polyethylene PE 1000), which ensures low noise level.

Request for a quote

UGUR MAKINA CRUSHING & SCREENING

Turkey

Belt conveyors are particularly successful in transporting bulk materials such as mineral ores, stone, sand and grain at high capacities and over long distances. A belt conveyor consists of an endless belt stretched between two drums. Belt conveyors are usually the most suitable solution when stacking material needs to be transported over long distances without stopping. They are used horizontally or with a low slope. The material to be transported can be sand or granule.

Request for a quote

KEDY

Turkey

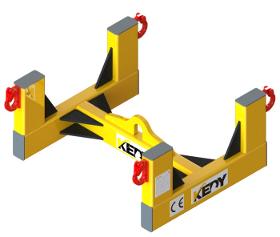

Introducing the KEDY K1300 Big Bag Lifting Beam, the ultimate solution for handling and moving large bulk materials with ease and efficiency! Our KEDY K1300 is specifically designed to handle big bags, the most common and cost-effective containers for storing and transporting dry bulk materials such as grain, sand, and fertilizer. The beam's sturdy frame and secure hooks make it easy to lift and move big bags safely and efficiently, reducing the risk of spills, damage to the bag, or injury to workers. One of the key benefits of the KEDY K1300 is its versatility. It can be used with a wide range of big bag sizes and can be attached to any crane or lifting equipment, making it ideal for use in a variety of industries and applications. So if you're looking for a reliable and efficient solution for handling and moving large bulk materials, look no further than the KEDY K1300 Big Bag Lifting Beam! Order now and start enjoying the benefits of hassle-free big bag handling.

Request for a quote

DONAT TRAILER

Turkey

Flatbed Semi Trailer designed for open and bulk cargo transport with Donat Trailers long term experience and engineering. Flatbed Trailer has many variety regarding cargo. structure and accesories of Flatbed Trailer make it quality trailer. All flatbed chassis welding made by certified welder. Finishing of Donat Trailer flatbeds are anti-rust painted and sand blasted.

Request for a quote

YONGMING MACHINERY MANUFACTURING CO., LTD

China

The belt conveyor is the more economical method of transporting bulk materials over short and long distances. This is ideal for conveying bulk materials of large lump size, such as crops,fruit, wood,sand,etc.It has a wide belt that slides over a metal bed for smooth,quiet conveying of items placed on the belt from point A to B.The layout of your plant can be simplified and made more efficient with the use of belt conveyors.

Request for a quote

YONGMING MACHINERY MANUFACTURING CO., LTD

China

The screw conveyor is system designed to transportation of loose bulk product from one place to another,alternatively used for waste treatment(shells,peels)loading and unloading the transportation vehicles or silos. The product moves up forward by means of spiral wings in the pipe; When the product reaches to the exit point, products discharged down from the spiral eject point.Using multiple discharge points,screw conveyors efficiently distribute bulk materials to different areas.

Request for a quote

KFB CLARFELD GERMANY GMBH

Germany

In the mining sector severe operating and environmental conditions require extremely robust bearings. Bearings for mining industry are used for bucket wheel excavators, draglines, conveyor belts, trucks, stackers, transport equipment, loaders, longwall shearers and hoists. The mining industries use many types of bearings: roller bearings, deep groove ball bearings, spherical roller bearings and tapered roller bearings. DEEP GROOVE BALL BEARINGS The mining industries use belt conveyors for transporting bulk materials. The conveyors run on idlers and a lot of them extend over many kilometers; thus the number of idlers needed may be very large. The deep groove bearings (design 2ZR and 2RS) are sealed by dust shields and seals on both sides, and filled with grease for a long service life. SPHERICAL ROLLER BEARINGS In the mining sector severe operating and environmental conditions require extremely robust bearings. Mining machinery faces some of the toughest terrains.

Request for a quote

GRONEMEYER MASCHINENFABRIK GMBH & CO.

Germany

The Gronemeyer aluminium system has stood the test of time for transporting general cargo and bulk goods across long distances. The design allows for non-cutting and fast installation. Common mat chains and drive engines are used. Here your requests can be taken into account. The drives are delivered as slip-on gears or with chain drive. The modular construction allows them to be re-used later for a new conveyor path. Supports, railing brackets, sensors, etc. can be positioned and affixed to the profile as desired with slot nuts. Technical data: —Conveyor body material: Aluminium/stainless steel —Chain width: up to 1400 mm —Conveying speed: up to 80 m/min Optional equipment: —Centre drive + automatic tensioning —Retracting end —Hinged nose —Moving deflecting pulleys —Product guides, fixed or adjustable, design depending on product —Supports to stabilise the conveyor systems at the desired conveying height —Other accessories, such as sensors, stoppers, etc.

Request for a quote

GRONEMEYER MASCHINENFABRIK GMBH & CO.

Germany

The Gronemeyer stainless steel hygiene system has stood the test of time for transporting general cargo and bulk goods across long distances. The open construction prevents dirt deposits and is suitable for conveying food without packaging. Common mat chains and drive engines are used. Here your requests can be taken into account. The drives are delivered as slip-on gears or with chain drive. The modular construction allows them to be re-used later for a new conveyor path. Technical data: —Conveyor body material: stainless steel —Chain width: up to 1400 mm —Conveying speed: up to 80 m/min Optional equipment: —Centre drive+ automatic tensioning station —Retracting end —Hinged nose —Chain washing station —Moving deflecting pulleys —Product guides, fixed or adjustable, design depending on product —Supports to stabilise the conveyor systems at the desired conveying height —Other accessories, such as sensors, stoppers, etc.

Request for a quote

BAUER GMBH

Germany

-The original BAUER shovel for handling and transporting bulk materials -simple pick-up using forks -can be emptied at any height by cable operated from the driver‘s seat -body walls with reinforced edging -special steel blade trim -sturdy frame -can be secured to prevent slipping Types available -Type BSE mechanical -Type BSE-H hydraulic -Type BSM mechanical, with trough opening for forks -Type BSM-H hydraulic, with trough opening for forks -Type BSI mechanical

Request for a quote

FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

Conveyor belts are often used to transport bulk materials over long distances, especially in the stone, soil, mining and brown coal industries. Despite good scrapers, material residue often remains on the conveyor belt because of striations and minor damage. The result large amounts of material accumulate beneath the conveyor belt system in the area of the return rollers, and have to be removed by costly cleaning work involving many workers. FTK TURN Operating principle The FTK TURN belt turning station made of highly wear resistant polyurethane turns the conveyor belt through 180 degrees after material transport directly in the reverse direction or into the lower drum. Because of the turning process, the inner, clean side of the belt which never comes into contact with the transported material now has its surface facing down towards the ground. Cleaning is a thing of the past!

Request for a quoteResults for

Transportation- bulk - Import exportNumber of results

39 ProductsCompany type

Category

- Goods handling systems, continuous (7)

- Conveyor belts (5)

- Pneumatic conveyor equipment (3)

- Concrete preparing - machinery and equipment (2)

- Containers, metal (2)

- Food canning and preserving - machinery and equipment (2)

- Bulk materials for construction (1)

- Container transport systems (1)

- Containers (1)

- Crushing and grinding machinery (1)

- Handling - Machines & Equipment (1)

- Lifting - vehicles (1)

- Lifting equipment (1)

- Lifting equipment - accessories (1)

- Oils, cooking - machinery and equipment (1)

- Plastic material processing (1)

- Quality control and certification (1)

- Tar and asphalt - construction materials (1)