- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- machine tools - metal machining

Results for

Machine tools - metal machining - Import export

BIMATEC SORALUCE ZERSPANUNGSTECHNOLOGIE GMBH

Germany

Machines of the T range are compact and ergonomically designed high performance bed type milling machines. They are characterized by optimum rigidity, mechanical stability, and high cutting capacity. The machine design guarantees optimum interaction between operator and machine. The areas of application include tool and mold making, mechanical engineering, and medium-sized precision parts in subcontracting. Longitudinal (X): 2,500 – 4,500 mm Vertical (Z): 1,500 – 1,600 mm Cross (Y): 1,200 – 1,500 mm

Request for a quote

BIMATEC SORALUCE ZERSPANUNGSTECHNOLOGIE GMBH

Germany

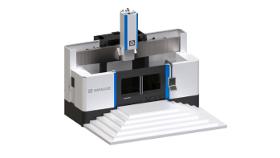

The portal and multitasking machines of the P series offer maximum precision and flexibility for machining large, complex and high-precision workpieces. Outstandingly suitable for machining prismatic and cubic workpieces in a single set-up and mounting position. An extremely heavy cast iron design with optimum damping properties and the INA linear guiding system equipped with hydro mechanical damping slides provide the basis for the ultra-modern table and gantry design portal machines. Areas of application: Mechanical engineering, new energy, tool and mold making industries, subcontracting sector and other industrial markets with very large, complex, and precision workpieces. - Table or gantry design with clamping tables of any size and NC rotary tables - Multitasking: Milling and turning on one machine Longitudinal (X): 3,000 mm - unlimited Vertical (Y): 1,500 – 3,000 mm Cross (Z): 4,000 – 10,500 mm Crossbeam (W): 1,000 – 4,000 mm

Request for a quote

BIMATEC SORALUCE ZERSPANUNGSTECHNOLOGIE GMBH

Germany

The VTC series of vertical turning machines offer maximum stability for vertical turning, milling, drilling, and grinding. The basis of the VTC series is a sophisticated technology with a cast iron design paired with modern linear guiding systems. All machines are hallmarked by optimum damping, maximum productivity through high cutting capacity, and an ideal machine concept for machining highly complex and precision workpieces. The machine design guarantees optimum interaction between operator and machine. Areas of application: Mechanical engineering, gear manufacturing, new energy sectors, and high-precision subcontracting. Table diameters: 1,800 – 7,000 mm Turning diameter: 2,100 – 8,000 mm

Request for a quote

BIMATEC SORALUCE ZERSPANUNGSTECHNOLOGIE GMBH

Germany

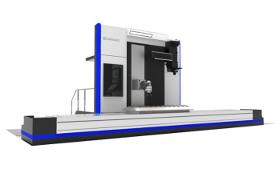

The SORALUCE KB-150-W series is a modern table-type horizontal boring machine for efficient multi-face machining of large and precision workpieces with weights of up to 40,000 kg. The heavy cast iron design and INA linear roller guide systems guarantee maximum stability and precision. The automatic milling head changing system provides exceptionally high flexibility thanks to the automatically lowering milling heads for machining at any angle. Longitudinal (X): 3,000 – 5,000 mm Vertical (Y): 2,600 – 3,200 mm Cross (Z): 2,000 – 5,000 mm

Request for a quote

BIMATEC SORALUCE ZERSPANUNGSTECHNOLOGIE GMBH

Germany

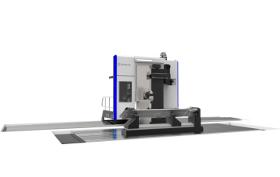

Floor type milling machines stand for flexibility, productivity, and maximum precision. All machines are hallmarked by optimum rigidity and dynamics and offer maximum productivity. The machine design guarantees optimum interaction between operator and machine. Areas of application include mechanical engineering, tool and mold making and contract manufacturing for machining large parts with heavy unit weights. - Machining of large parts in pendulum mode - Machine for large workpieces with precision Longitudinal (X): 3,000 mm – unlimited Vertical (Y): 1,800 – 8,000 mm Cross (Z): 1,300 – 1,900 mm Quill (W): 700 – 1,000 mm

Request for a quote

BIMATEC SORALUCE ZERSPANUNGSTECHNOLOGIE GMBH

Germany

Multitasking machines for combined, precise milling, turning, and grinding of complex workpieces. Unique ergonomics and user-friendliness for optimum operation and work processes thanks to low machine table with integrated vertical rotary table and open access to the work area. Optimal machine concept for the production of single workpieces and series production. - Machining of complex workpieces in one clamping operation Longitudinal (X): 2,500 – 4,000 mm Vertical (Z): 1,250 – 1,800 mm Cross (Y): 1,200 – 1,500 mm NC-rotary table: Ø 1,250 – 2,000 mm

Request for a quote

BIMATEC SORALUCE ZERSPANUNGSTECHNOLOGIE GMBH

Germany

Machines of the S range are ergonomic milling machine with gigantic work area for long, large, bulky, and heavy workpieces. Modular system to meet individual customer requirements. Perfect for high-precision tool and mold making, mechanical engineering, and subcontracting. - Ideal for multi-station machining - Maximum precision for decades - Machine for large workpieces with power - New design for even greater ergonomics - User-friendly and innovative technology Longitudinal (X): 3,500 – 40,500 mm Vertical (Z): 1,800 mm Cross (Y): 1,300 – 1,500 mm

Request for a quote

F. ZIMMERMANN GMBH

Germany

The core technology is a robust, water-cooled travelling column. With increasing depth of immersion into the material, the guide carriage distance grows and this leads to advanced rigidity. The stepped drive guide ensures a perfectly constant geometry along the Z axis. This in turn guarantees maximum rigidity in sensitive areas of the workpiece. Used in combination with the highly dynamic Zimmermann milling heads, the FZH400 ensures an extremely efficient milling process during the machining of aluminum and composites. The versatility of the M3ABC 3-axis milling head improves efficiency due to the maximized material removal rate, in particular when machining structural parts. An integral standard component of the FZH400 is its pallet handling capability with an area for setting up pallets during machine operation. The newly developed handling system permits the reliable transportation of the pallets, is suitable for longer pallet lengths, and can be extended without difficulty.

Request for a quote

EWS WEIGELE GMBH & CO. KG

Germany

EWS.PSC offers maximum stability and rigidity coupled with maximum flexibility. Significantly reduce your setup and changeover times while maintaining high mold flexibility. he EWS.PSC program includes a wide range of standard tools with PSC shank for milling spindles as well as tool systems with PSC spindle for lathes. Furthermore, tool holders with plate seat are available. The interface allows you to reduce the time spent measuring, setting up and changing tools. In addition, improved machine utilization can be achieved.

Request for a quote

EWS WEIGELE GMBH & CO. KG

Germany

The new EWS tcJet range Optimal chip transport thanks to EWS tcJet EWS tcJet transports the coolant through the inset directly to the cutter and guarantees optimal chip transport... At the same time, the cutting edges have a significantly longer service life. EWS's interior cooling version is available for normal and high-pressure applications for various tool holder fixtures and cutting insert manufacturers.

Request for a quote

EWS WEIGELE GMBH & CO. KG

Germany

EWS goes milling With its latest range of angular heads, EWS brings its trusted technology with new features to machining centres. The system range was presented to the public for the first time at EMO 2015. An elegant design houses high-performance technology, or to put it simply Precision meets Motion. Advantages: the smart solution for compensating for there not being a machining axis Machining hard-to-reach parts Centre boring stepless angle adjustment around the horizontal axis, with tangentially acting double cone clamp MR > 250 Nm Prerequisite: The prerequisite is a "stop block" on the machine. This prevents the entire unit from turning while simultaneously defining the position of the angel of rotation. Variations: basic duplex offset Request form: PDF

Request for a quote

EWS WEIGELE GMBH & CO. KG

Germany

High-speed thread cutting with reversing kinematics The new EWS Tapmatic thread cutting head for driven tools enables thread cutting processes without having to reverse the direction of rotation thanks to its reversing kinematics. This saves time and energy and protects the motor – all this with a defined depth of thread. The units are available for M3-M12 threads.

Request for a quote

EWS WEIGELE GMBH & CO. KG

Germany

Emulsion can do more than just cool... At least when using EWS Spinjet, the coolant is used to drive a turbine which allows the tool to rotate to up to 50,000 rpm, depending on the type. The turret's tool drive stops moving during this process! See the attached flyer for the technical requirements and details. Download Manual: PDF

Request for a quote

EWS WEIGELE GMBH & CO. KG

Germany

Trifix® is the new adjusting system for Gildemeister multi tasking machines. The double sided adjusting system is guided by a very precise key way at the surface of the turret. The plates are preloaded, and the resiliency in the adjusting system eliminates static redundancy. This allow the exact position of the tool to be secured and significantly reduces the setup time of the machine. Because this is a highly sophisticated precision instrument it is not possible to use double serrated tool shafts. The tool is supplied fully adjusted and can be used right away. EWS is the DMG system partner for this tool generation. Trifix® advantages: Repeat accuracy below 6 µm at radius of 200 mm High positioning accuracy from one station to another (0.01 mm) Driven tools and static tool holders are completely aligned Static tool holders can be used together with additional drill pattern for mounting Heavy duty spindle noses can be used together with additional d

Request for a quote

EWS WEIGELE GMBH & CO. KG

Germany

Mount tools safely and in the correct position while remaining flexible, all this is possible with the UMB100 mounting unit. The tool clamping units can be changed quickly, making the system an ideal mounting aid for multi-tasking machines. It only takes a few seconds to replace an adapter. The unit with snap-in swivel can be pivoted 4 x 90° at the touch of a button so that even angled holders can always be mounted in the ideal position. Universal mounting block UMB100 Tool holder for VDI holding fixtures Tool holder for Varia VX Tool holder for steep-angle taper holding fixtures

Request for a quote

EWS WEIGELE GMBH & CO. KG

Germany

Keyway broaching on lathes is a common thing. What is new is to speed up this operation with low stress for the machine! Slot is driven by the tool turret of the machine, with the input rotary motion being converted to a translation with superimposed lift-off function. This makes programming extremely easy. The keyway broaching unit is positioned in the prepared bore – in such a way as to make the extended tappet oriented to the end position in the Z axis. The depth of the slot is produced by a constant X-feed moving between 0.04-0.08 mm/stroke. The speed of the spindle ranges between 400 R/min – 1,000 R/min, with one rotation corresponding to a complete stroke. This way, for instance, a feather key groove with a width of 6 mm and a depth of 5 mm is produced within 7.5 sec. (800 R/min and 0.05 mm feed/rotation). With this operation it is important that the chip can break at the end of the groove, that is that a cut-in or a bore exists.

Request for a quote

EWS WEIGELE GMBH & CO. KG

Germany

Reaching concentricity 0 using a simple collet chuck and this within one minute: this is Zero-Zero. The specifically designed clamping nut with 6 symmetrically arranged screws at the circumference makes this step possible. The clamping nut is split, so that the inner ring can be minimally shifted. This simple technical finesse allows to eliminate tolerance additions. The machine operator only has to replace the previous clamping nut, which step opens up a new concentricity dimension – and this for a price starting at € 90.00. Zero-Zero is available for DIN 6499 collet chuck holders from ER 16-ER40.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

EWS WEIGELE GMBH & CO. KG

Germany

EWS quality now available for Swiss-type lathes. This new development in driven tools is EWS's response to many customers' requests. The tool systems may appear straightforward at first sight, but their simplicity belies their performance. The design concentrates on the mounting and the spindle concentricity. The requirement profile was developed jointly with an American medical technology company which uses very small drill bits and requires extreme concentricity properties. The spindle bearing technology used with labyrinth seals sets new standards in this field, and is associated with a long service life. Provision has already been made for service. The service centres in Germany, China, Korea and the USA have already been trained in the system and are ready to respond without delay. Third-party brands can also be serviced there at any time. Download catalogue: PDF

Request for a quote

EWS WEIGELE GMBH & CO. KG

Germany

EWS takes measures against vibrations in deep drilling procedures Deep drilling procedures with drilling rods with a long overhang are one of the most demanding tasks in cutting technologies. What influences vibration, what amplitudes does it create, what is the effect of superimposed vibration and when are uncontrollable resonances encountered? All these are questions that are difficult to answer using theory alone. These findings formed the basis for the new development of EWS Rigid. The objective was to create a drilling holder with a passive damping system to counteract the vibrations that are created. This involves using variable vibration dampers with linear degrees of freedom in a floating mounting inside the cutter carrier. The damper position is set using a radially mounted setscrew, which allows optimum vibration conditions to be created. The improvement in surface qualities of bores is significant, as is the increase in the service life of cutter tools.

Request for a quote

EWS WEIGELE GMBH & CO. KG

Germany

The best of both worlds! Insufficient stability was a fact increasingly associated with the VDI system in recent years. As a result, block tools were preferred more often, although the VDI tools still offer greater diversity and flexibility. So the next step appeared obvious: combining the best of both systems. In cooperation with DMG, we developed the EWS ProLine system in order to fully utilize the potential of new lathes. While EWS ProLine features a conventional VDI shank, it can be optionally mounted to the turret using four screws. For instance, the flexibility of the VDI system can be utilised for lighter machining, and the stability properties of block tools can be utilised for heavy cutting. The angular position of the radial tools is ensured through the Trifix®, the alignment system. Cutting data similar to HSK63 machining centres? The professional audience at the EMO 2011 watched an impressive live demonstration: on a Gildemeister CTX Beta 1250 4A, two surf

Request for a quote

EWS WEIGELE GMBH & CO. KG

Germany

Make any centric or eccentric form desired 4, 6, or 8 edged, polygonal or free form with the EWS Multiform on the CNC turning/milling machines Free forms that used to be impossible can now be made with EWS Multiform on turning/milling or machining centres. For a six-edge outside the centre or a four-edge in the centre, additional processing steps such as reaming or eroding were necessary up until now. If a position change was also needed, complicated devices were needed for processing. This is now all possible with one chuck. What is behind this? EWS Multiform uses a custom internal cam disc unit to produce the required form. For conventional geometry like squares or hexagons, there are standard cam discs available. The cam forces the cutting tool to follow a path in order to get the desired geometric shape. Of course you can’t defy the laws of physics which means that there will be a small radius on the edges.

Request for a quote

EWS WEIGELE GMBH & CO. KG

Germany

Gear hobbing on CNC lathes without B-axis Years ago, EWS was the first tool manufacturer to offer gear hobbing heads in its standard range, and has continued to develop the holders for gearing technology ever since then. With this technology, it became possible for the first time to produce external gearing on machines without a Y/B-axis. In contrast to a standard milling wheel holder, the tool head of the EWS modular cutter can be swivelled about the axis of the shank. This offers users the advantage of substituting a B-axis with a comparatively small investment. In the meantime, module 3 has become commonplace on VDI40/BMT65/BMT75 machines. The tool heads have become more stable at the same time as being more user-friendly. The alignment system using a sinusoidal profile has come into widespread use and saves considerable alignment and setup times. Operating instructions, flyers and press reports can be found in our download portal Video: Gear hobbing on the

Request for a quote

EWS WEIGELE GMBH & CO. KG

Germany

The changeable centring tip for counter spindles Would you like to use your counter spindle temporarily as a tailstock, and then once again as a normal chuck? You can with the EWS CenterPoint Area of application: Lathes without tailstock and with a turret To support long tools Top changeable short taper 12 The top kit can be integrated in simple combination holders Prerequisite: Counter spindle with tailstock function Taper shank adjusted to GSP Machining process: Milling on the main spindle Switch to tip in GSP Use tip rotating Execute machining Remove tip from GSP Pass work piece to GSP, work second side

Request for a quote

EWS WEIGELE GMBH & CO. KG

Germany

The rapid change system EWS-Varia allows to set-up a modern CNC lathe or a turning milling center – and this flexibly. A tool change will just take 20 seconds, which is an unbeatable argument especially in small batch productions whenever it is about reducing the set-up time and thus increasing the productivity. The advantages, however, are also evident in large batch productions. Preset twin tools lie at the machine, thus significantly reducing the down-times. A further advantage is provided by the variety of adaptations; so the optimal tool clamping can be selected for each operation. The inserts available include: Collet chuck holders Weldon/Whistle Notch Milling arbors Morse tapers Hydro extension Shrink adaptations The most important advantage is certainly created by the easy handling. The inserts can be changed with just one hand without counter pressure by the spindle.

Request for a quote

EWS WEIGELE GMBH & CO. KG

Germany

Static tools form one of the EWS core areas. There is no other manufacturer in the world offering such a variety of products: More than 20,000 different tool holders are available for machine operators. Our portfolio includes VDI tool holders with shaft diameters of 16-80 as well as block tool holders of BMT55-BMT85 to machine-specific holders for MAZAK, Okuma or Mori Seiki, to name just a few. We also offer prism holders according to DIN 69881 (VDI3425 Bl.3) in all nominal sizes. Our standard portfolio includes Capto, HSK, KM and ABS adaptations in addition to the standard holders. Moreover, our scope of supply includes special holding fixtures made according to customer drawings or innovative solutions of the EWS engineers designed to master production engineering challenges. The tool holders are manufactured at our factory in Uhingen and rightly carry the label: Made in Germany! Boring bar holder BMT Capto C4 Double boring bar holder Capto Bar Gripper Infee

Request for a quote

EWS WEIGELE GMBH & CO. KG

Germany

Driven tools form a further core area of EWS. More than 8,000 different tools are available at short notice. In addition to standard products like axial and angular heads, EWS offers swivel units, slot broaching tools, multiform tools and multi-spindle machines. There is just no limit. The tool clamping systems range from the classic collet chuck holder to Weldon and hydro extension to Capto, KM, ABS and HSK. The applications range from classic CNC lathes to highly complex turning milling centers. The rapid change system EWS-Varia has set a standard for a flexible modular system. With its safe handling and short change-over times, EWS-Varia ranks among the most successful systems in the market. This was impressively confirmed by the Innovation Award awarded by the German state of Baden-Württemberg in 2006. "Made in Germany" is of course guaranteed by EWS also for these tool systems.

Request for a quote

STARRAG GMBH

Germany

The vertical lathes of the TVU product line of Berthiez are especially suited for machining engine and turbine components, which are primarily used in the aerospace industry as well as for alternative and classical power generation. The TVU vertical lathes are characterized by a complete cast design, highprecision static and dynamic positioning as well as longlasting reliability. Advantages of the TVU vertical turning lathes are, completely cast iron construction, high static and dynamic axis stability, high accuracies and long term reliability. For higher flexibility the machine can be equipped with several pallet change systems and adaptable milling heads. The optional Yaxis table traverse will permit the turning, milling and grinding of complex components in a single clamping

Request for a quote

STARRAG GMBH

Germany

The vertical lathes of the TVU product line of Berthiez are especially suited for machining engine and turbine components, which are primarily used in the aerospace industry as well as for alternative and classical power generation. The TVU vertical lathes are characterized by a complete cast design, highprecision static and dynamic positioning as well as longlasting reliability. Advantages of the TVU vertical turning lathes are, completely cast iron construction, high static and dynamic axis stability, high accuracies and long term reliability. For higher flexibility the machine can be equipped with several pallet change systems and adaptable milling heads. The optional Yaxis table traverse will permit the turning, milling and grinding of complex components in a single clamping

Request for a quote

STARRAG GMBH

Germany

The vertical lathes of the TVU product line of Berthiez are especially suited for machining engine and turbine components, which are primarily used in the aerospace industry as well as for alternative and classical power generation. The TVU vertical lathes are characterized by a complete cast design, highprecision static and dynamic positioning as well as longlasting reliability. Advantages of the TVU vertical turning lathes are, completely cast iron construction, high static and dynamic axis stability, high accuracies and long term reliability. For higher flexibility the machine can be equipped with several pallet change systems and adaptable milling heads. The optional Yaxis table traverse will permit the turning, milling and grinding of complex components in a single clamping.

Request for a quoteResults for

Machine tools - metal machining - Import exportNumber of results

142 ProductsCountries

Company type

Category