- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- pastries

Results for

Pastries - Import export

FORMEX MAQUINARIA

Spain

-It dispenses liquid and semi-liquid batter. -It replaces the piping bag to great advantage: it is faster, more convenient, more precise, does not damage the dough, the machine does not drip and the trays do not get dirty. -Exact volumetric dosing is easily adjustable. It turns a slow process into a semi-automatic process. -By simply placing your foot on the electric foot pedal, you fill a row of muffins in the tray. -The tray feed is manual. -It can be cleaned in one minute and takes up minimal space. FOR MAKING: muffins, sponge cakes, sobaos, cakes, shortbread, cakes, pancakes, mayonnaise, marble cake, yoghurt, custard, mousse, sauces, milkshakes, creams, products without solid particles.

Request for a quote

FORMEX MAQUINARIA

Spain

•For dosing cakes into moulds of different shapes and sizes. •The mixture can have solid particles incorporated. •Exact dosage of the product from 100 to 1,500 cc, •The dosage is volumetric and the number of doses for each stop can be configured from the screen, in case more doses are needed to fill the mould. •It can work with delicate masses. Different elements of the dosing machine can be custom-configured: type of dosing nozzles, heated tank, conveyor belt, topping dispenser, etc., and adapted to the characteristics of the product to be dispensed. •TO MAKE: marble cake, musician's cake, plumcake, mouse cake, cheesecake, chocolate cake, etc.

Request for a quote

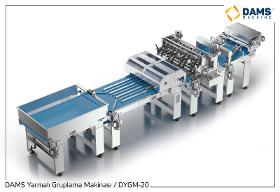

DAMS MACHINE

Turkey

The settings are made easily from the PLC-controlled touch screen. Mechanical settings are simple to use and easy to learn. Information on usage can be stored in memory and used continuously. Daily cleaning is easy. It is easy to disassemble, install and replace belts and running parts. The speeds of all belts can be adjusted to the desired level. Electrical and electronic faults that may occur are displayed on the PLC screen with pic and text.

Request for a quote

DAMS MACHINE

Turkey

Our machine is used in bagel, roll, sandwich and hamburger breads. Machine settings can be made on PLC and digital display. These settings are saved in the recipe and do not want to be re-adjusted in product change. Machine chassis is made of 304 Cr-Ni sheet metal. It has the feature of spraying the desired amount of water, eggs, slurry and molasses on top of the products in the flat tray or molded tray. At the same time, it can sprinkle the desired amount of granular materials such as sesame, bran, kernel, rye on the products on the flat tray or molded tray. It is simple to use and clean.

Request for a quote

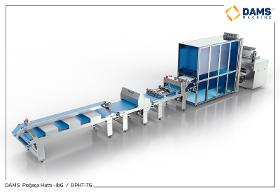

DAMS MACHINE

Turkey

Sandwich and hamburgers coming from the cooling tower or in bulk are placed manually between the product sorting slides with the help of two personnel. When the products are divided into groups, the numbers are checked with the sensors, and if there are missing rows, they wait until the order is completed. The queues are divided into groups by the help of two flaps, and the number of packages depends on desired grouping (sandwich 4, 5, 6, Hamburger 4, 6, 8). Here, the products are placed between the product pushers of the packaging machine with the help of a push rod. Product pushers take products to the enveloping unit and allow them to be packaged.

Request for a quote

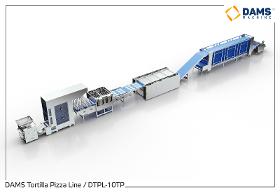

DAMS MACHINE

Turkey

It can cut sandwiches and hamburgers, flatbread, bagels, baguettes and similar products. It is used in the slicing (cutting) process of sandwich and hamburger breads before packaging. The slicing machine has wheels and can be taken anywhere easily. The chassis is completely chrome nickel. Used strip blade, easy to disassemble and install. The surfaces that the product comes into contact with are made of tape suitable for food. Product feeding is done manually.

Request for a quote

DAMS MACHINE

Turkey

It is used in splitting (cutting/ slicing) the sandwich and hamburger breads before packaging. Circular blade is used, this blade is easy to remove and install. 304 Cr-Ni is manufactured on the surfaces that the product touches. The bands used are suitable for food. Product feeding is done manually. There are three adjustment arms; First Setting Arm It is top pressing setting. The top band is adjusted according to the thickness of the bread to be split and the bread is prevented from flying during cutting.

Request for a quote

DAMS MACHINE

Turkey

It is used in splitting (cutting/ slicing) the sandwich and hamburger breads before packaging. Circular blade is used, this blade is easy to remove and install. 304 Cr-Ni is manufactured on the surfaces that the product touches. The bands used are suitable for food. Product feeding is done manually. There are three adjustment arms; First Setting Arm It is top pressing setting. The top band is adjusted according to the thickness of the bread to be split and the bread is prevented from flying during cutting.

Request for a quote

DAMS MACHINE

Turkey

The settings are made easily from the PLC-controlled touch screen. Mechanical settings are simple to use and easy to learn. Information on usage can be stored in memory and used continuously. Daily cleaning is easy. It is easy to disassemble, install and replace belts and running parts. The speeds of all belts can be adjusted to the desired level. Electrical and electronic faults that may occur are displayed on the PLC screen with pic and text.

Request for a quote

DAMS MACHINE

Turkey

DIVIDER & ROUNDER Upto 11000 pcs/hour capacity Weigh trange 40-140 grams (±2 gr) 6 pieces 50mm diameter pistons Changable outer drum for different weights 6 row outlet belts Automatic oil lubrication Variable speed controls for main drive and rounding unit Flour duster Dough bunker capacity is 210 kg Total power 5 kW 7 inc HMI TouchPanel , PLC control.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

DAMS MACHINE

Turkey

GENERAL CHARACTERISTICS Sandwich and hamburgers coming from the cooling tower or in bulk are placed manually between the product sorting slides with the help of two personnel. When the products are divided into groups, the numbers are checked with the sensors, and if there are missing rows, they wait until the order is completed. The queues are divided into groups by the help of two flaps, and the number of packages depends on desired grouping (sandwich 4, 5, 6, Hamburger 4, 6, 8).

Request for a quote

DAMS MACHINE

Turkey

The settings are made easily from the PLC-controlled touch screen. Mechanical settings are simple to use and easy to learn. Information on usage can be stored in memory and used continuously. Daily cleaning is easy. It is easy to disassemble, install and replace belts and running parts. The speeds of all belts can be adjusted to the desired level. Electrical and electronic faults that may occur are displayed on the PLC screen with pic and text.

Request for a quote

FORMEX MAQUINARIA

Spain

WITH THIS MACHINE YOU WILL BE ABLE TO MAKE: Butter biscuits, almond doughs, curly biscuits, homemade biscuits, polvorones, perrunillas, mantecados, etc. •Uniform and fast production, avoiding punishing the dough or any alteration of its natural characteristics. •For medium and large productions, depending on the product and model. •Easy and quick change of moulds. •Intelligent production management by means of HMI panel, recipe programming. WIRE CUTTING AND MOULDS WITH A GREAT VARIETY OF SHAPES AND SIZES: For dense or hard doughs.

Request for a quote

FORMEX MAQUINARIA

Spain

WITH THIS MACHINE YOU WILL BE ABLE TO MAKE: Tea cakes, sponge cakes, meringues, plum-cake, homemade pastries, perrunillas, mantecados, polvorones, alfajores, cream biscuits, cookies, madeleines, sponge cake sheet, macaron, cup-cakes, almond dough biscuits, cat's tongues, etc. -Uniform and fast production, avoiding punishing the dough or any alteration of its natural characteristics. -For medium and large productions, depending on the product and model. 50-200 Kg/h. -Easy and quick change of the different accessories to work multi-product. -Intelligent management of the production by means of HMI panel, recipe programming. THREAD CUTTING AND MOULDS WITH A GREAT VARIETY OF SHAPES AND SIZES: For dense or hard doughs. SWIVELING AND FIXED NOZZLES: For semi-dense doughs. PUMP HEAD: For semi-dense or fluid doughs.

Request for a quote

FORMEX MAQUINARIA

Spain

•Dosing machine for making muffins, muffins and other food products with two-coloured dough. •Machine made for the dosing of two different doughs in the same capsule or mould. •The tank is divided into two parts to place each mixture in one of them. •The dosing outlet has off-centre nozzles to be able to adjust the depositing point of the mass. •The dosing parameters for each product can be changed independently via the touch screen. •Approximate production of 170-230 trays/hour approx.

Request for a quote

FORMEX MAQUINARIA

Spain

THE MIXING MAY INCLUDE INCORPORATED SOLID PARTICLES such as chocolate chips, nuts, candied fruit, etc. -For medium and large productions depending on the degree of automation of the bakery. -The volumetric dosing of the product is exact and guarantees the same dose in all the nozzles. -The dosing control is managed by a servo motor system. -Through the touch screen the user can control the quantity of doses as well as the speeds of both loading and unloading of the product. Different elements of the dosing machine can be custom-configured: number of nozzles, tray width, heated tank, conveyor belt, to adapt to the characteristics of the product to be dosed. FOR MAKING muffins, muffins, cakes, shortbread, sponge cakes, ponquets, brownies, plum-cake, sobaos, pancake, marble cake, creams, yoghurt, tarts, sauces, soup, flan, brandade, mousse, croquette paste...YOUR PRODUCT.

Request for a quote

FORMEX MAQUINARIA

Spain

Units to apply topping such as chocolate pieces, sugar, peanuts, hazelnuts, grated coconut, almonds and granules on the already dosed product. -Very flexible machine, adapts to all types of topping. It works multi-product. -The topping is deposited in an outlet hopper and moves along a belt until it falls through funnels and remains on top of the product. A screed would maintain a homogeneous measure of the product on the belt. This system favours the regular depositing of the fragments throughout the product. Adjustable output speed and product flow. -There are 3 ways to adjust the dosage: -By the flusher to the deposit (mechanical). -By the speed of the belt with sugar (electronic). -By time of movement of the belt. -Modifications can be made by touch screen with different programmes depending on the product. -Machine that works as an independent unit. A conveyor is added and it works autonomously.

Request for a quote

FORMEX MAQUINARIA

Spain

-INJECTOR MACHINE FOR FILLING cream, chocolate, jam, marmalade, dulce de leche, etc. into muffins, muffins, croissants and other bakery products in the same baking tray, avoiding unnecessary handling of the product. -Exact and easily adjustable volumetric dosage. -It replaces manual filling processes with great advantage: it is faster, more comfortable, more precise, it does not damage the dough, the machine does not drip and the trays do not get dirty. It turns a slow process into a semi-automatic process. -By simply placing your foot on the electric pedal, we fill a row of muffins in the tray. -The tray feed is manual. -It can be cleaned in one minute and takes up minimal space.

Request for a quote

FORMEX MAQUINARIA

Spain

MACHINE CHARACTERISTICS: -Production line consisting of three stations: oInjector with three rows of nozzles to inject 27 croissants simultaneously, and with three needles per nozzle so that the product is well distributed. oGelatine station that impregnates the croissants with gelatine. oTopping unit with ribbon for the chocolate chips to fall onto the product and get stuck in the gelatine layer. -Injection quantity and injection speed are set on the screen, allowing a more precise adjustment. -Between the injection belt and the gelatine belt, which is made up of cords, there is a transfer belt so that the croissants fall correctly in position and without turning, and are stacked for the gelatine shower. ADVANTAGES -Automated production for high volume production. -Three processes are completed in a reduced space.

Request for a quote

JING HENG SING TECHNOLOGY CO., LTD.

Taiwan R.O.C.

We provide various turnkey food production lines. Please contact us with your detailed request. Thank you. good@cooker.com.tw

Request for a quoteResults for

Pastries - Import exportNumber of results

38 ProductsCompany type