- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- pressure reducing valve

Results for

Pressure reducing valve - Import export

TURKOGLU

Turkey

Diaphragm Pressure Reducing Valve DN15-DN25 ** / Body : Brass ( CW617N-CuZn40Pb2) / Connection : Threaded (FF) / Type : With union, with gauge (manomater) / Max. Working Temp. : 120 ºC / Max. Working Pressure : 16 Bar *** Application Areas : Hot and Cold Water Systems

Request for a quote

TURKOGLU

Turkey

Body and Cover : ASTM A-536 Cast Iron / Valve Inner Parts: Bronze ASTM B61 / Pilot Control Valve and System: Bronze ASTM B62 w / Stainless Steel 303 Inner parts / Valve diaphragm: Buna-N neoprene ** Connection Type: Flanged / Pressure :16-25 Bar / Working Temp.:+4ºC , + 80ºC *** Increases the system equipment life and save the water in tank which is used for unnecessary operations. These valves are used to reduce the pressure which is over the limits on the system. **** Application Areas: After hydraulic calculations, If any pressure adjustment is needed, pressure reducing valves are suitable.

Request for a quote

EM-TECHNIK GMBH

Germany

The 5D pressure reducing valve is used to reduce system pressures to largely constant working pressures. Due to its design it requires extremely low maintenance in applications and is therefore suitable for horizontal and vertical installation.

Request for a quote

DELTA TECHNIK FILTERSYSTEME GMBH

Germany

Our installation systems with integrated safety control block are suitable for installation in pressurized lines. The integrated safety control block consists of a volume flow reduction unit and a pressure reducing valve. These two components make this system become a cost-effective, very safe, and technically fast operating solution. The mounting to existing systems and machines can be completed in just a few minutes, because there are only 2 connections and mounting material is also part of the system.

Request for a quote

VENN CO., LTD.

Japan

Model: RP-6 Code: RP6-B Applicable fluid: Steam, Applicable primary pressure: Max. 1.0MPa Adjustable seconday pressure: 0.03-0.8MPa Maximum reducing rate (inlet: outlet)/20:1 Applicable temperature: Max. 184 Deg.C End connection: Flanged JIS 10K FF Materials: Body/ Cast iron Disc & seat/ Stainless steel Piston & cylinder/ cast bronze Minimum pressure differential across the disc: 0.05MPa Size: 15mm-80 mm Minimum pressure differential across the disc: 0.07MPa Size: 100 mm -200mm

Request for a quote

ARMAS SU ARMATURLERI

Turkey

Armas “PR” model pressure reducing control valve is the hydraulic control valve which reduces high upstream pressure value into desired lower pressure value by means of built-in pressure reducing pilot valves. Pressure reducer control valve controls downstream pressure value continuously and maintains it constant without being affected from flow rate and upstream pressure values. When no flow exists in the system, it is closer by itself automatically. When valve upstream pressure value decreases below adjusted downstream pressure value, it is opened fully by itself. Valve may be user in vertical and horizontal positions in the system.

Request for a quote

ASCO CARBON DIOXIDE LTD

Switzerland

The ideal and reliable highflow CO2 pressure reducing valve for use with CO2 gas or liquide. Constructed in brass (C31) and meehanite (C2K32) with stainless steel trim Abrasion and dirt resistant rubber valve seats Dome loading either from inlet line or separate gas supply Stable and noiseless operation Positive gastight shutoff Highflow contoured passages

Request for a quote

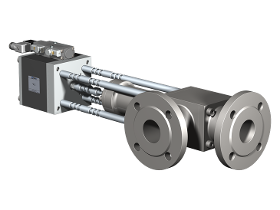

SCHUBERT & SALZER CONTROL SYSTEMS GMBH

Germany

The self operated pressure regulator type 8011 with closed spring cover in the form of a pressure reducing valve (downstream pressure regulator) or an excess flow valve (upstream pressure regulator) is used in a wide range of process engineering control tasks. Media such as steam, liquids, gases, etc. can be excellently controlled without auxiliary energy.

Request for a quote

SCHUBERT & SALZER CONTROL SYSTEMS GMBH

Germany

The self operated pressure regulator Type 8011 in a reinforced version with closed spring cover in the form of a pressure reducing valve (downstream pressure regulator) or an excess flow valve (upstream pressure regulator) is used in a wide range of process engineering control tasks. Media such as steam, liquids, gases, etc. can be excellently controlled without auxiliary energy.

Request for a quote

ASCO CARBON DIOXIDE LTD

Switzerland

Typically, the ASCO CO2 Gas Dosing System is used together with water desalination plants. The system is equipped with a CO2 pressure reducing valve, filtration unit, CO2 gas flowmeter, CO2 regulating valve, pressure gauges, safety valves and a completely prewired control cabinet. In case of maintenance the system provides a manual bypass line, which also can be monitored by the flowmeter. Herefore, changing a filter cartridge or doing any other service work on the system is quick and easy! As raw and fitting material ASCO uses mainly stainless steel. This makes the system very resistant and extends the products life cycle. easy to install very accurate 4 20 mA output signal robust stainless steel construction no auxiliary equipment like air compressor needed, only power supply is required

Request for a quote

STRATE TECHNOLOGIE FÜR ABWASSER GMBH

Germany

The STRATE non-return valve RKS is particularly suitable in areas where the prevention of flap impacts is of particular importance. In this application case the extension of the standard butterfly valve RSK by the additional component STRATE spring load (RSK-FT or RSK-FTU) is required Product features (STRATE RSK) Wide flap to prevent piercing, especially at high pressure levels Type RSK-FT: Equipped with exterior spring load to more quickly close the flap and avoid flap impact Type RSK-UD: Bypass line with pressure shock damping valve to reduce/avoid pressure shocks Type FTUD: a combination of the above types to optimally protect the pumps in case of a power outage, etc.

Request for a quote

TECNIDRO

Italy

The valve reduces high upstream pressure to a pre-set lower and constant downstream pressure level, regardless of fluctuating flow or varying upstream pressure. A hydraulic regulating pilot drives the valve. The pilot is able to detect upstream pressure values and regulates closing steps of the valve until the pre-set pressure value is restored.

Request for a quote

TECNIDRO

Italy

The valve reduces high upstream pressure to a pre-set lower and constant downstream pressure level, regardless of fluctuating flow or varying upstream pressure. A hydraulic regulating pilot drives the valve. The pilot is able to detect upstream pressure values and regulates closing steps of the valve until the pre-set pressure value is restored.

Request for a quote

JET FLOW TECHNOLOGIES UK LIMITED

United Kingdom

A Steam Conditioning Valve / Combined PRDS Valve is the combination of pressure reduction and temperature reduction of superheated steam to fit process needs, protect downstream equipment or allow the use of less expensive materials or schedules for downstream piping. This is done with a pressure reducing valve and a spray water addition section either as separate units or a single device. Pressure reduction is carried out with a pressure reducing trim within the valve body, usually multi stage pressure reduction. The pressure is controlled by an upstream or downstream pressure controller, signaling the valve to modulate to maintain the pressure at the required set point.Temperature is controlled by adding water to the steam in such away that it will get fully evaporated in the steam, termed as desuperheatmg. These applications are normally considered to be some of the most severe services of any valves in a modem steam plant.

Request for a quote

CERTUSS DAMPFAUTOMATEN GMBH & CO. KG

Germany

You require a mobile steam plant or you want to install a steam plant outside your plant building? Then the complete installation within a container is the ideal solution for you. The container steam plant contains all the required components – from the water treatment plant through to the steam trap. - CERTUSS steam generator - CERTUSS CVE supply unit - Feed water treatment - Steam distributor - Pressure reducer station - Clarification valve - Steam dryer - Condensate elevating system - Steam trap - Interior lighting of the container - Insulated pipe installation in the container - Emergency-off switch - Steel door or uPVC door - High-quality stainless steel wall with insulation - Outside coating as required The installation and commissioning of the container plant at the customer is on request either carried out completely or only partially (if an external installation company is used) by our customer service.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

GLÄSNER SANDSTRAHL MASCHINENBAU GMBH

Germany

The injector-glass-blasting cabin is operated by hand with a gun. A blast-collecting collector ensures a smooth blasting circuit within the system. With the help of roller rails, as well as through-slots (on the side and in the roof surface with special brushes against the penetration of dust), surface treatment of glass panes is easy. On the front side there is an easy-open loading door for radiating hollow glass bodies. A work grate and two shock-proof long-field lamps (for glare-free illumination of the blasting chamber) guarantee a smooth workflow. The foot switch as well as the drain cup on the blasting agent funnel, an attached control box with pressure reducing valve and pressure gauge, motor protection switch, on / off button, solenoid valve, control lights, switches for interior lighting, main switch, emergency stop switch and support control ensure uncomplicated operation.

Request for a quote

GLÄSNER SANDSTRAHL MASCHINENBAU GMBH

Germany

The housing is made of folded stable sheet steel and welded. In the cabins 2 workports with built-in rubber sleeves (easily exchangeable) are incorporated. The cabin is equipped with a blast hose, nozzle holder and nozzle 1 made of hard metal. For the different requirements are made of hard metal nozzle with a diameter of 0.8 mm, 1.0 mm or 1.2 mm for selection. All blasting medium-pressure vessel (1 - 3 Tank System) have a volume of 2 kg and provided with a closure cap. In all systems, a pressure reducing valve and a pressure gauge for setting a constant jet pressure, and compressed air supply are fitted with plug-in nipple. All systems are equipped with a pneumatic foot switch for turning on and displaying the blasting process.

Request for a quote

TEKNOMASYON

Turkey

-Hydraulic Mini power packs -Hydraulic pumps, -Hydraulic Motors, Orbit Motors -Hydraulic power units and various hydraulic systems -Solenoid, Pilot, Manuel operated hydraulic directional control valves -Hand Valves -Relief, pressure, reducing, speed control valves, check valves, throttle valves -Modular and plate designed valves -Control blocks and hydraulic switch -Hydraulic Cylinders -Oil Coolers #hydraulicsystems #hydrauliccylinders #minipowerpacks #GearPumps #HydraulicMotors #HandValves

Request for a quote

MÜLLER CO-AX GMBH

Germany

This type is a pneumatically actuated valve with 2 port connections and 2 switching positions. The V2 has been developed for hot gases up to 400°C.

Request for a quote

MÜLLER CO-AX GMBH

Germany

Within the family of pressureregulating valves, a technical distinction is made between series of bypass valves, inline valves and threeway valves.

Request for a quote

TURKOGLU

Turkey

Body: ASTM A-536 Cast Iron / Valves : Bronze Surface covered with Teflon, Stainless steel Trim Set / Pilot control valve and system: Bronze ASTM B62 and Stainless steel 303 inner parts ** Connection Type: Flanged / Pressure :16-25 Bar / Working Temp.: +4ºC , + 80ºC *** This valves using for the preventing damages which cause from the pressure in fire pump systems. Generally fire protection systems use the diesel pumps and electrical motors. In that systems relief valves are preferred. **** Application Areas: In systems which has diesel or electrical high pressure fire fighting pumps.

Request for a quote

EM-TECHNIK GMBH

Germany

Series 5D pressure keeping valves are used to eliminate overpressures due to operation or due to the system. It eliminates pressure peaks by relieving the system if the set pressure is exceeded. Both versions of the pressure keeping valve can be installed horizontally or vertically in any installation position, allowing for versatile use.

Request for a quote

TURKOGLU

Turkey

Test and Drainage Valves / Body: Brass ( Forged ) / Ball : Brass / Gasket : PTFE ** Connection Type: Threaded or Grooved / Working Pressure: 300 PSI ( 20,6 Bar ) / Working Temp.: -10ºC , +120ºC / Working Test Pressure: 600 PSI (61,8 Bar) *** In sprinkler systems, these valves are used for the testing systems and drain the unnecessary fluids from the systems. Advantages: They have sight glasses in their body,single valve is sufficient to drain the line. For choosing the test and drain valves, users should pay attention to line diameter. Also these valves have to have same diameter with the sprinkler orifice diameter. **** Application areas: The system where has sprinkler systems.

Request for a quoteResults for

Pressure reducing valve - Import exportNumber of results

26 ProductsCompany type

Category

- Valves for industrial fittings (6)

- Pressure regulators (4)

- Cooling and lubrication pumps (2)

- Fire detection and alarm equipment (2)

- Industrial valves, operating equipment (2)

- Plastics - industrial machinery and equipment (2)

- Sandblasting equipment (2)

- Boilerwork (1)

- Fire alarms and detection - equipment and systems (1)

- Fire protection equipment (1)

- Hydraulic equipment (1)

- Oil filters (1)

- Steam turbines (1)

- Water - production and distribution (1)