- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- rotary die-cutter

Results for

Rotary die-cutter - Import export

WHITECROFT ESSENTIALS (LYDNEY) LTD

United Kingdom

Because quality counts, OLFA designs, develops and manufactures its products in Japan. Ever since the OLFA CORPORATION, invented the world's first snap-off blade cutter in 1956, OLFA has been committed to developing practical and safe hand-held cutting tools. OLFA brand blades are made with top quality materials, forged with technologies that stem from traditional sword-making, sharpened with technologies that give a blade life, and ultimately finished with the craftsmanship that brings all of this together. The holders and handles that allow users to gain the full cutting performance of these high-quality blades are designed, developed and manufactured in Japan and subjected to stringent quality checks throughout the process.

Request for a quote

BOGRAMA AG

Switzerland

Individual products are fed to the punching area from the flat pile feeder and punched with the rotating flexibe die. The sheet alignment on the side is performed with a register table with ball rail. The position accuracy in the direction of production is realised with a positioner roller system that causes the sheets to pass the punching punching cylinder with high precision without stopping. Inline configuration of the die-cutting machine with machines interfaced downstream such as folding machines, mailing systems and packaging machines is the most efficient way of carrying out multiple high-performance steps in one operation. Automatic discharging of section grids and simultaneous separation of inner cuts increase production in addition. The format range of the BSR 550 Servo is from 550 x 750 mm to 210 x 210 mm. Sheets having a product thickness between 0.5 mm and 80 g/m2 can be processed. The maximum capacity of the machine is 12,000 sheets/h

Request for a quote

BOGRAMA AG

Switzerland

This machine configuration is the most flexible variant. It can not only be combined with downstream but also with upstream equipment such as cross cutters, digital printing machines and folding machines. Products are fed individually to the punching area via register table and rotary punched by using a flexible die. The sheet alignment on the side is performed with a register table with ball rail. The position accuracy in the direction of production is realised with a positioner roller system that causes the sheets to pass the punching cylinder with high precision without stopping. Automatic discharging of section grids and simultaneous separation of inner cuts increase production in addition. The format range of the BSR 550 Servo is from 550 x 750 mm to 210 x 210 mm. Sheets having a product thickness between 0.5 mm and 80 g/m2 can be processed. The maximum capacity of the machine is 12,000 sheets/h.

Request for a quote

BOGRAMA AG

Switzerland

"The compact and attractively priced BSR 550 basic is structured as an offline solution. It is designed specifically for users who want to produce small and medium runs economically and efficiently as well as for those for which the flexible connection options and technical features of the BSR 550 Servo have no priority. Individual products are fed to the punching area from the flat pile feeder and punched with the rotating flexibe die. The sheet alignment on the side is performed with a register table with ball rail. The position accuracy in the direction of production is realised with a positioner roller system that causes the sheets to pass the punching cylinder with high precision without stopping. To exchange the flexible dies the entire breakout and deliver unit is disconnected from the die-cutting area. Thus an optimal accessibility is guaranteed. After die-cutting the inner cuts are separated and the section grids deflected.

Request for a quote

BOGRAMA AG

Switzerland

In this configuration variant, products are fed to the punching area individually from the pallet feeder and rotary punched by using a flexible die. The maximum stack height of the feeder is 100 cm. The sheet alignment on the side is performed with a register table with ball rail. The position accuracy in the direction of production is realised with a positioner roller system that causes the sheets to pass the punching cylinder with high precision without stopping. Inline configuration of the die-cutting machine with machines interfaced downstream such as folding machines, mailing systems and packaging machines is the most efficient way of carrying out multiple high-performance steps in one operation. Automatic discharging of section grids and simultaneous separation of inner cuts increase production in addition. The format range of the BSR 550 Servo is from 550 x 750 mm to 210 x 210 mm. Sheets having a product thickness between 0.5 mm and 80 g/m2 can be processed.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

DOREY

France

From the innovators of welding automation, Miller Weldmaster presents the i6500W Series of Indexing welders. This recipe driven curtain producer will enable your operator to easily finish your vertical webbing and vertical seams effortlessly. After the fabric is placed on the automatically driven table, the welding head will advance to the start position and finish all of the vertical webbings hands free. All webbing are pre fed, pre cut, and precisely positioned with no measuring. Speed, versatility, precision and labor reduction... the model i6500W. Also available To weld horizontal webbings on truck curtains To weld anti vandalism webbings SPÉCIFICATIONS, FONCTIONS ET BÉNÉFICES Throat capacity available in 6.5m to 14m Independent Quad heat system Automatic rotary webbing cutter Miller Weldmaster PLC Smart Screen Custom indexing clamp system High speed hot air welding technology Power friendly worldwide

Request for a quote

ALTMANN GRAPHISCHE MASCHINEN GMBH

Germany

width 52 cm age 1996 web width 520 mm max. web diameter 1270 mm web edge control Erhardt + Leimer 2 wet offset printing units 630 mm circumference cooling unit Technotrans turning bar after unit 1 air fluided turning bars rotary cutter Q 74 edge trimming both sides sheet delivery Uniplus 520 tab inserter Ref: MU240065S Please ask for price. We ship and install worldwide!

Request for a quote

VIRMER

Netherlands

WATTSAN 1530 ROTATORY has a rotary device for cutting cylindrical products. This machine is purchased for cutting steel tubes, galvanized and stainless steel, aluminum, brass and other materials. The machine is most often used in aviation, aerospace and mechanical engineering, as well as for the manufacture of auto parts, advertising products and household appliances. You can install a radiator of any power: 300/500/750/1000/1500/2000/3000/4000/5000 Watts. Important: the machine is equipped with a protective cabin with a power of 1000 Watts. Optional fiber laser emitter: Max / Raycus / IPG. Each of them is distinguished by high accuracy and speed of work, durability, but there are also differences. IPG is considered a premium model, it gives the best result and speed. The service life of the emitter ignition unit is about 100 000 hours. The protective glass for the lens, which must be changed at least once a month. The lens itself needs to be renewed approximately once a year.

Request for a quote

FLEXPLAS

Turkey

State-of-the-art design for the application Flexplas offers a wide range of Cutters including Servo Cutters, Servo Flywheel (Rotary) Cutters, Pneumatic Guillotine Cutters, Cut-Saws and Haul-Off Cutter (Caterpillar Puller-Cutter) Units to meet the exact requirements of the application and industry. High precision, easy repeatable cutting Flexplas high precision FLEXI-CUT Series Cutters allow cutting all types of flexible hoses, tubes, and small profiles, including hoses embedded with wire. We design and construct Flexplas cutting units with tailor-made cuts as per customer’s project requirements. FLEXI-CUT Series Cutting Machines are suitable for cutting hoses and profiles by means of saw blades or cutting blades, and they link seamlessly with your extrusion line. Advanced technology ensures the precision, repeatable accurate cutting of hoses, tubes, tapes, and profiles always for superior production. Easily adaptable to high line speeds.

Request for a quote

WHITECROFT ESSENTIALS (LYDNEY) LTD

United Kingdom

For over 100 years Whitecroft has been manufacturing & Exporting a wide range of Haberdashery & Desktop Office Essentials. In addition to the respected Essentials Brand we also specialize in 'Own Label' packaging of most products we offer. Starting as a Pin manufacturer it quickly included Safety Pins and Paperclips to its range. In the following 100 years, it built a strong brand recognised for quality Haberdashery Notions and Knitting products. We also became the UK Distributor for Olfa Rotary Cutters, Mats & Rulers plus Rapid Glue guns & Tackers. The Stationery side of the business specialised in Desktop Essentials, all the small everyday items used in the office. We also became the UK Distributor for the Hopax Stick'n Brand of Sticky Notes & Repositional paper products. Please visit our website www.whitecroft.co.uk or contact our sales team on +44 (0)1594 546464 for further information.

Request for a quote

BOGRAMA AG

Switzerland

Mobile transfer unit for inline operation with the BSR 550 Servo rotary die-cutter. For the perfect gripping of die cut products. Fitted with clocked air nozzles for the separation of inner cuts.

Request for a quote

BOGRAMA AG

Switzerland

With the new Automated Card Production System for inline die-cutting, collating and stacking of playing cards you can die-cut a wide range of cards including playing cards, gaming cards, trading cards and sports cards and they can be stacked and delivered in one step. The system consists of the market leading BSR 550 Servo rotary die-cutter, feeding into the ACC 550 HS Automatic Card Collator. The cards are die-cut nick-free, stripped out inline, shingled and fed to the ACC 550 HS Card Collator via a conveyor belt. The ACC 550 HS stacks each row into a complete deck and feeds it to a downstream packaging system that may include over wrappers, banding machines, packaging machines or packing table conveyors. With production rates of up to 2,000 decks per hour, the highest quality cutting, makeready times in under 1 hour and an automated delivery that reduces labor to a single person, the BOGRAMA Automated Card Production System has the ROI needed to be the market leader.

Request for a quote

FERNITE OF SHEFFIELD LIMITED

United Kingdom

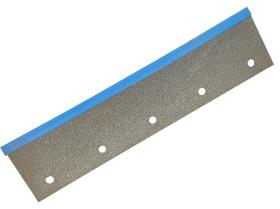

The global food industry is vast, and the processing machinery that supports it constantly demands high quality, durable and reliable knives to sustain and protect output. Safe in the knowledge that every Fernite knife is manufactured in our own Sheffield plant from the finest steel on the market, you can rely on us to keep your machines running to the max. Proud to support the world’s greatest brands, we supply a huge range of standard and bespoke machine knives and blades for the food industry including: Scraper blades for rotary moulder, drum dryer machines and refiner blades Freezer blades Rotary cutters Guillotine blades Peeler machine knives Potato chipper knives Specialist bakery knives Chopper blades Vegetable peeler knives Slicer and dicing blades Flow wrap knives Packaging machine blades. Tray seal knives Bowl chopper knives Extruded food cut-off knives Nut slicers Onion cutters Pizza cutters Cheese cutter knives

Request for a quote

MASCHINENBAU BARDOWICK GMBH

Germany

The Rotary Cutter RC is designed for the precise cutting of hoses and profiles made of rubber or plastic up to a maximum diameter of 100 mm and at line speeds of up to 300 m/min. A clean cut quality and minimized length tolerances characterize our rotary cutter. Maschinenbau Bardowick GmbH (formerly DCM Maschinenbau GmbH Lüneburg) has been a leading manufacturer in the field of extrusion downstream equipment for decades. Customer-specific special solutions are developed and implemented by us. The advantages of the Rotation Cutter RC Optimized cutting length tolerances through specially developed cam profile application Servo controller of the latest generation Low space requirement due to compact design High effectiveness with simple operation The Rotation Cutter RC at a glance A cut-to-length system with the highest quality The rotary cut-to-length RC machine meets your high quality requirements in many aspects.

Request for a quote

MASCHINENBAU BARDOWICK GMBH

Germany

The combined cutting machine CC is designed for the precise cutting of hoses and profiles made of rubber or plastic up to a maximum diameter of 100 mm and at line speeds of up to 300 m/min. A clean cut quality and minimized length tolerances are the hallmarks of our combined cutting system. Maschinenbau Bardowick GmbH (formerly DCM Maschinenbau GmbH Lüneburg) has been a leading manufacturer in the field of extrusion downstream equipment for decades. Customer-specific special solutions are developed and implemented by us. The advantages of the Combi Cutter CC Low space requirement through combination of the caterpillar BP and the rotary cutter RC Precise transport speed due to servo axes of the latest generation Optimized cutting length tolerances through specially developed cam application High effectiveness with simple operation The Combi Cutter CC at a glance A cut-to-length system with the highest quality

Request for a quoteResults for

Rotary die-cutter - Import exportNumber of results

16 ProductsCompany type

Category

- Punching machine tools (5)

- Cutters (3)

- Textiles - Machines & Equipment (2)

- Blades and knives, industrial (1)

- Extrusion, plastics - machinery (1)

- Flexography - machines (1)

- Paper - processing machinery (1)

- Rubber and plastic cutting operations (1)

- Stationery (1)

- Steels and metals - forming and cutting (1)