- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- sterilization containers

Results for

Sterilization containers - Import export

ILLIYYUN SAV. OTO. DAN. LTD.

Turkey

Sterilization Containers Accessories Container Security Seal Container Label Container Filter

Request for a quote

ASEL MEDIKAL A.S.

Turkey

We offer various models and sizes of containers designed and manufactured to serve various purposes in all Health Institutions and Institutions. Containers designed for the sterilization of medical instruments and equipment,preserving the sterile state of sterilized instruments, handling of these sterile instruments, the transfer and storage between units can be given as examples. Our company supports the containers with numerous accessories such as wire baskets, silicon mats, textile products, filters, tags etc. Our containers are produced from anodized aluminum.

Request for a quote

BÜRKLE GMBH

Germany

The sample containers sterile are sterilised by irradiation and correspond to a sterility assurance level Sterile SAL 10-3 (according to ISO 11137) inside. The handy and universally applicable sample jar is easy to fill, smooth-walled and free of undercuts, therefore it can be emptied completely. It is an excellent universal container for all liquid and solid contents. The attached lid of the sample container can be opened with one hand and fixed at a 90° angle. This leaves the other hand free to take samples. Liquid/condensate in the lid runs into a collecting channel integrated in the lid, nothing is lost, nothing can drip off. The sample boxes are closed while hot during production. Due to this process, the sample boxes close absolutely tightly, as the lid and box adapt optimally during the cooling process. The sample container made of PP is highly transparent, the contents of the container can be easily recognised.

Request for a quote

KASAG SWISS AG

Switzerland

The KASAG sterile containers, mixing tanks are used for preparing and mixing of products in the food industry. The container is equipped with a mixing device and jacket for heating and cooling. The entire system is built on a frame with a control unit and weighing cells.

Request for a quote

FLUX-GERÄTE GMBH

Germany

Pre-assembled pump kit for food and pharma. The pump-kit is ideal for hygienic applications and suitable for conveying media out of drums, IBCs and other containers. It can be easily and quickly disassembled for cleaning / sterilization and can be completely stripped down to individual parts. Comprising drum pump FP 427 FOOD, outer tube stainless steel 1000 or 1200 mm, commutator motor F 458, hose, hand nozzle, hose connection and compression gland. Product attributes: - Sealless in the liquid area - Minimal dead spots - Can be taken apart completely in only a few steps - Disassembly almost without tools possible Benefits: - Ideal as hygienic pump - Can be quickly and easily taken apart for cleaning - All parts in contact with the medium can be sterilized - Transfers also fluids containing solids such as juices with pulp or soups with spices - Appropriate for food contact acc. to EC 1935/2004 and FDA CFR 21 - Also available for the ex-area with drum pump FP 430 Ex FOOD

Request for a quote

FLUX-GERÄTE GMBH

Germany

The Drum pump F/FP 427 is ideal for hygienic applications and suitable for conveying media out of drums, IBCs and other containers. It can be easily and quickly disassembled for cleaning / sterilization and can be completely stripped down to individual parts. The pump has minimal dead spots. The drive shaft, the inner and the outer tube are made of stainless steel (316 Ti resp. 1.4581). The pump is also available as FOOD and 3A certified version and complies with international safety standards. Benefits: - Ideal as hygienic pump - Can be quickly and easily taken apart for cleaning - All parts in contact with the medium can be sterilized - Transfers also fluids containing solids such as juices with pulp or soups with spices - Available with different connection at the pressure side (e.g. Clamp 1 1/2" or RD 58x1/6) - Available with 3A Certificate - Available as FOOD version - Appropriate for food contact acc. to EC 1935/2004 and FDA CFR 21

Request for a quote

UNIPLAST DOO

Serbia

The process of sterilisation is among the most complex ones when dealing with plastic materials. Plastic materials cannot be sterilised with high temperature because they would be permanently physically deformed. The containers are sterilised with ionising radiation (y radiation) or with gas and moisture (gas sterilization). Products which are packed for sterilization are packed in multilayer packaging in order to meet custumer´s requirements (standards) for proper upgrade of products from lower to higher level of purity. Every batch of sterilised products is accompanied by an adequate sterilization documentation. The efficiency of every sterilization process is checked by an adequate biological indicator.

Request for a quote

UNIPLAST DOO

Serbia

Pharmaceutical plastic containers (a closure is a part of the container) are used for packing (storing) vagitories and suppositories (magistral medicine, galenical medicine, readymade medicines). They can be in direct contact with the product. The pharmaceutical plastic containers are made from materials that are described in Ph.Eur. and they meet the criteria of the specific use assessment that are also described in Ph.Eur. We buy the materials from highly reliable producers. We offer the possibility of packing the containers in a secondary plastic container (catalogue number 16125). The conditions and the method of production of plastic containers and closures are in accordance with the following standards ISO 9001, ISO 14001, and OHSAS 18001. Customers can choose the colour of the container (proof of additives) and whether they want containers to be sterile or not.

Request for a quote

UNIPLAST DOO

Serbia

Plastic containers for sticks and inhalers are used for packing (storing) products for general use. They can be in direct contact with the product. The conditions and the method of production of plastic containers and closures are in accordance with the following standards ISO 9001, ISO 14001, and OHSAS 18001. Customers can choose the colour of the container (proof of additives) and whether they want containers to be sterile or not. With the containers we deliver producer´s certificate that is accompanied by technical documentation and documentation which states that the final products and materials they are made from are safe for health (traceability of product´s documentation).

Request for a quote

UNIPLAST DOO

Serbia

Powder bottles (plastic containers) for pharmaceutical use are used for packing (storing) pharmaceutical products (pharmaceutical substance, magistral medicine, galenical medicine, readymade medicines). They can be in direct contact with the product. The bottle under the catalogue number 25150 (150ml) is a „tamperproof“ container (its closure has a tamper evident band) because it ensures that the package is original and not opened. These containers can have a perforated inner closure. The conditions and the method of production of plastic containers and closures are in accordance with the following standards ISO 9001, ISO 14001, and OHSAS 18001. Customers can choose the colour of the container (proof of additives) and whether they want containers to be sterile or not.

Request for a quote

UNIPLAST DOO

Serbia

Spray bottles (plastic containers) for pharmaceutical use (a closure is a part of the container) are used for packing (storing) liquid pharmaceutical products (magistral medicine, galenical medicine, readymade medicines). They can be in direct contact with the product. The pharmaceutical plastic containers are made from materials that are described in Ph.Eur. and they meet the criteria of the specific use assessment that are also described in Ph.Eur. We buy the materials from highly reliable producers. The conditions and the method of production of plastic containers and closures are in accordance with the following standards ISO 9001, ISO 14001, and OHSAS 18001. Customers can choose the colour of the container (proof of additives) and whether they want containers to be sterile or not.

Request for a quote

UNIPLAST DOO

Serbia

Spray bottles (plastic containers) for pharmaceutical use (a closure is a part of the container) are used for packing (storing) liquid pharmaceutical products (magistral medicine, galenical medicine, readymade medicines). They can be in direct contact with the product. The pharmaceutical plastic containers are made from materials that are described in Ph.Eur. and they meet the criteria of the specific use assessment that are also described in Ph.Eur. We buy the materials from highly reliable producers. The conditions and the method of production of plastic containers and closures are in accordance with the following standards ISO 9001, ISO 14001, and OHSAS 18001. Customers can choose the colour of the container (proof of additives) and whether they want containers to be sterile or not.

Request for a quote

UNIPLAST DOO

Serbia

Plastic containers with tamper evident band for pharmaceutical use are used for packing (storing) firm pharmaceutical products (magistral medicine, galenical medicine, readymade medicines, and pharmaceutical substance). They can be in direct contact with the product. These containers are „tamperproof“(closures with tamper evident band) because they ensure that the container is original and not opened. The pharmaceutical plastic containers are made from materials that are described in Ph.Eur. and they meet the criteria of the specific use assessment that are also described in Ph.Eur. We buy the materials from highly reliable producers. The conditions and the method of production of plastic containers are in accordance with the following standards ISO 9001, ISO 14001, and OHSAS 18001. Customers can choose the colour of the container (proof of additives) and whether they want containers to be sterile or not.

Request for a quote

UNIPLAST DOO

Serbia

Transparent plastic containers are used for packing (storing) semifirm and firm cosmetic and food products. They can be in direct contact with the product if the product does not have a high vapor pressure. Every plastic container can have an innerseal. The conditions and the method of production of plastic containers and closures are in accordance with the following standards ISO 9001, ISO 14001, and OHSAS 18001. Customers can choose the colour of the container (proof of additives) and whether they want containers to be sterile or not. With the containers we deliver producer´s certificate that is accompanied by technical documentation and documentation which states that the final products and the materials they are made from are safe for health (traceability of product´s documentation).

Request for a quote

GUNDEM SAGLIK VE GIDA URUNLERI SAN. VE TIC. A. S.

Turkey

The sterilization documentation system is used for patientrelated traceability of all medical sterilization processes. The documentation page contains all the necessary information to release the sterilization batch. One sterilizer and one documentation sheet for the day are used. Using a labeling device (Label Gun), the documentation sheet and each package can be labeled with a selfadhesive label containing the following information • Production and expiry date, •Person in charge, • The contents of the packaging, • Sterilizer and batch number. All packages on the lot and documentation pages have the same label content and lot number. After opening the sterile package in the OR, the top layer of the label can be peeled off and affixed to patient and/or operative documentation. The content of the label allows for followup on the patient's return to batchrelated documentation in the sterilization department.

Request for a quote

HELAPET LIMITED

United Kingdom

Range of products include: Absorbant Workmats Ampoule Breaker (sterile and non-sterile) ChemoSorb Pad Polypropylene Containment Socks Polypropylene Pillows Spill Kits Sterile Sharps Bins (0.6L, 2.5L, 5L and 7L)

Request for a quote

WHITE STEEL GMBH

Germany

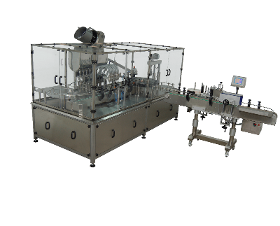

DESCRIPTION High stability on high capacity. Can handle multiple bottles size, types and shapes Type of metal used S.S 316 / 304 Certifications ISO 90012015, OHSAS 180012007, ISO 500012011, ISO 450012018 SPECIFICATION 6 Diving Nozzles One feeding table HMI and SCADA system with touch screen integrated user friendly and simplified software. Available certification up on your request UL, CE, GMP, FDA, ASME. Available documents up on your request I.Q (Installation qualification), O.Q Operational qualification), P.Q Performance qualification. Linear filling system. Star containing, sterilizer, capping and closing system One side labeling machine.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

SHANGHAI MARYA PHARMACEUTICAL ENGINEERING AND PROJECT CO., LTD.

United States

Shanghai Pharmaceutical BFS Machine is an advanced technology that integrates molding, filling, and sealing under complete control, which enables liquid to be packaged in polypropylene/high-density & low-density polyethylene plastic bottle, and the whole production process automatically completes the followings in a controlled environment (aseptic environment): Extrude plastic particles into plastic perform at high temperature. Then the perform is blown into a container by sterilized and filtered air. Filling liquid that has been sterilized and filtered. Tight sealing of containers after filling. Shanghai Pharmaceutical BFS Eye Drop Plastic Ampoule Bottle Production Machine is suitable for liquid filling in pharmaceutical, chemical, and food industries with aseptic or non-aseptic packaging in plastic containers.

Request for a quote

CHITOTECH

Iran

Sterile hemostatic and absorbable powder, containing particles of oxidized regenerated cellulose which is suitable for all types of bleedings, arterial venous and capillary. The most important outcome after coronary angiography via femoral artery is to achieve fast and effective hemostasis. Due to the superabsorbent nature of this powder, when applied to the puncture site, following the removal of the catheter the serum of the jetting blood is absorbed by the powder. As a result, the rate of blood flow from the puncture site is reduced which in return accelerates the initiation of clot formation. The application of ChitoHem hemostatic powder on the patients has reduced the time to hemostasis significantly compared to the conventional manual compression.

Results for

Sterilization containers - Import exportNumber of results

20 ProductsCountries

Company type

Category

- Bottles and jars, plastic (8)

- Import-export - medical and surgical equipment (2)

- Portable electrical pumps (2)

- Sterilisation and disinfection - medical equipment (2)

- Food industry - machinery and equipment (1)

- Laboratory equipment and instruments (1)

- Mechanical engineering - custom work (1)

- Pharmaceutical industry - machinery and equipment (1)

- Pharmaceutical products (1)

- Quality control and certification (1)

- Tapes, adhesive (1)