- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- mechanical engineering - custom work

Results for

Mechanical engineering - custom work - Import export

KASAG SWISS AG

Switzerland

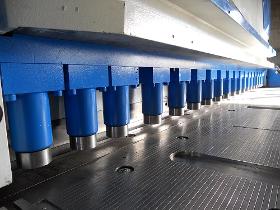

We have many years of experience in grinding and brushing of stainless steel surfaces for all object forms, as well as in the manual and machine grinding of circular objects. Our combined grinding machine/plant can be universally used, owing to its modular construction; it is of premium quality and guarantees surface roughness for stainless steel surfaces, on the inside and the outside for cylinders, spherical heads and cones for grinding welding seams superelevations for grinding longitudinal and circular welding seams roots

Request for a quote

KASAG SWISS AG

Switzerland

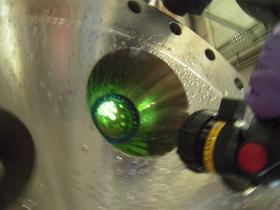

Nonporous welding and sealing technology are the central criteria for building vacuum chambers and vacuum apparatuses. KASAG has specific knowhow that it has gained over many years as well as a great deal of experience. Comprehensive, internal tests, such as the helium-leakage test, guarantee the absolute leak-tightness of your KASAG products. With KASAG, you remain leak-proof.

Request for a quote

KASAG SWISS AG

Switzerland

KASAG is a qualified sub-supplier for nuclear technology, for which we have an ASME-manufacturer permit. We process stainless steel and special materials for you corresponding to nuclear standards with regard to material traceability and quality documents. With KASAG as partner, safety comes first. Cryo technology is used for generating extremely low temperatures of under -150°C. Special physical effects can be used in the process for liquefaction and separation of gases. Manufacturing pressure containers for cryogenic temperature applications requires specific welding processes and certified KASAG welding specialists. For even for lowest temperatures KASAG is your first choice.

Request for a quote

KASAG SWISS AG

Switzerland

The task of storing liquids hazardous to water or to their processing must be handled responsibly. In the building of the corresponding process containers, storage tanks, stainless steel containers, different factors must be taken into consideration. They are designed according to regulations, such as PED (AD-2000, SVTI, EN13445) or according to special standards, such as the Basel chemical standard BN76 and manufactured in stainless steel. Process containers and storage tanks have half-pipe coils, jackets or laser-welded structures (pillow plates) for heating and cooling purposes. KASAG is the competent place if you are looking for replacement, modification, extension or reconstruction of complete tank plants. We will share your responsibilities.

Request for a quote

KASAG SWISS AG

Switzerland

Pressure vessels/containers and reactors must meet the highest quality requirements. The pressurized objects are designed at KASAG according to the relevant regulations and subsequently produced, with great enthusiasm, using the most modern technology. Stainless steel and special materials, such as duplex and nickel-based alloys (Hastelloy, Inconel) are processed. All our production experts have the mandatory certificates, and have mastered the welding process MIG, MAG, TIG, Plasma and Orbital and work solely with certified welding consumables. The pressure vessles and chemical reactors are finally polished, pickled, passivated and tested using non-destructive test methods. KASAG products meet all your standards.

Request for a quote

KASAG SWISS AG

Switzerland

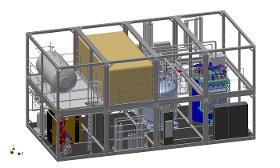

You now operate in an environment where production safety and perfect product quality have top-most priority. You must be able to place unlimited trust in your partners and to demand everything you need. With KASAG as your partner in design, engineering and production of apparatuses, pressure vessels, pressure containers, reactors, heat exchangers, modules and plants for global use, you are on the safe side. Core competences of KASAG: Design, calculation, construction according to diverse regulations, pressure equipment approvals, such as PED (EN13445, AD-2000), ASME (U-Stamp), China Stamp (A1), TP TC 032/2013 (EAC) Manufacturing permits and knowhow for the delivery of pressurised containers, apparatuses, plants to almost all the countries in the world. Welding of stainless steel and special materials such as Hastelloy, Inconel, Duplex Comprehensive spectrum of non-destructive tests Surfaces that meet the highest standards

Request for a quote

KASAG SWISS AG

Switzerland

We take on contract processing for you for complex welded constructions weighing up to 12 tons in aluminium, stainless steel and special materials. As a flexible partner, KASAG has the important permits and testing procedures. KASAG is your expert in welding.

Request for a quote

KASAG SWISS AG

Switzerland

Reactors must meet the highest quality requirements. The pressurized objects are designed at KASAG according to the relevant regulations and subsequently produced, with great enthusiasm, using the most modern technology. Stainless steel and special materials, such as duplex and nickel-based alloys (Hastelloy, Inconel) are processed. All our production experts have the mandatory certificates, and have mastered the welding process MIG, MAG, TIG, Plasma and Orbital and work solely with certified welding consumables. The pressure vessles and chemical reactors are finally polished, pickled, passivated and tested using non-destructive test methods. KASAG products meet all your standards.

Request for a quote

KASAG SWISS AG

Switzerland

You now operate in an environment where production safety and perfect product quality have top-most priority. You must be able to place unlimited trust in your partners and to demand everything you need. With KASAG as your partner in design, engineering and production of apparatuses, pressure vessels, pressure containers, reactors, heat exchangers, modules and plants for global use, you are on the safe side. Core competences of KASAG: Design, calculation, construction according to diverse regulations, pressure equipment approvals, such as PED (EN13445, AD-2000), ASME (U-Stamp), China Stamp (A1), TP TC 032/2013 (EAC) Manufacturing permits and knowhow for the delivery of pressurised containers, apparatuses, plants to almost all the countries in the world. Welding of stainless steel and special materials such as Hastelloy, Inconel, Duplex Comprehensive spectrum of non-destructive tests Surfaces that meet the highest standards

Request for a quote

KASAG SWISS AG

Switzerland

KASAG undertakes cutting, forming and welding works for manufacturing simple and complex welding constructions of up to a weight of 13 t in stainless steel and aluminium. Our specialists have been certified according to ISO 3834-2 in all required welding processes MIG, MAG, TIG, plasma and orbital.

Request for a quote

KASAG SWISS AG

Switzerland

KASAG has many years of experience in staining and passivating stainless steel and aluminium alloys. Our services for single objects are invoiced according to the expense and effort invested, or in the case of larger objects, according to prior quotation. For serial parts, the unit price is taken as the basis for invoicing. Bath pickling: 1,900 x 900 x 800 mm Sprays pickling: 6,000 x 3,000 x 2,500 mm (max. object size)

Request for a quote

KASAG SWISS AG

Switzerland

With our highly modern 3D plasma cutting equipment, we undertake plasma cuts of spherical bottoms/heads, dished boiler heads, pipes, profiles and metal sheets in material thickness of 1 - 50 mm. Metal sheet change:2,000 x 3,000 mm (2,000 x 6,000 mm) Pipes, profile:diameter 30 - 500 mm / length 3,000 mm (6,000 mm) Heads, cones: up to diameter 2,500 mm Material thickness:1 - 50 mm

Request for a quote

KASAG SWISS AG

Switzerland

KASAG is a highly qualified partner for undertaking contract manufacturing on your behalf. Our machines and equipment for premium processing of stainless steels and aluminium alloys always allow us to meet any demand you might have. Machine for object size Container diameter up to Ø 4 m Object weight up to 13 t Object length up to16 m Material zone with Cr ? 19%, Ni ? 8% (1.4307, 1.4571, ...) with Cr ? 19%, Ni ? 12% (1.4539, 1.4828, …) Duplex (1.4462, 1.4410, …) Alloys NiCrFeMo mit Ni > 40% (Inconel, Hastelloy) Alloys Al – Mn und Mg (AlMg 4.5 Mn)

Request for a quote

KASAG SWISS AG

Switzerland

Our specialists have vast knowledge and many years of experience in non-destructive testing (NDT) of welding seams, welding constructions, pressure vessels, containers, equipment and plants. We use and offer the following testing procedures for that purpose: X-rays RT Dye penetrant testing PT Visual inspection VT Material testing/ Positive Material Identification PMI Helium leakage testing LT Riboflavin test Pressure tests of up to max. 1000 bar Surface roughness testing Ra/Rz Ferrit measurement Fe Wall thickness measurement Video endoscopy Pressure-loss test (liquid) With KASAG, you remain on the safe side.

Request for a quote

KASAG SWISS AG

Switzerland

We bring your ideas to life KASAG has a high level of competence, with many years of experience in design and construction of plants, apparatuses, pressure vessels, pipes and welded structures. Our engineers can assist you with the following: Strength calculation according to the global regulations, such as PED (EN13445 / AD-2000), ASME (U-Stamp), China Stamp (A1), TP TC 032/2013 (EAC) FEM-calculations (Finite element analysis) and providing proof for overpressure and underpressure, load alteration, earthquake, joint flanges, nozzle loads Consultancy for interpreting and analyses of computation results, material choice, regulatory authorities Constructive, design based on Autocad 2D and Inventor 3D Comprehensive plants engineering, such as compilation of technical specifications, P&I schemes, risk analyses, pipeline/piping planning

Request for a quote

KASAG SWISS AG

Switzerland

Are you using pressure vessels, apparatuses, pressure containers that are subject to the inspection cycles of the regulatory authorities? Would you like to have our advance expertise on the technical updates? Do you have problems with the cleaning of apparatuses, containers? Are you unsure about the technical details of the bought-in containers, apparatuses, and would you like them checked? We are experts in apparatus and pressure vessel construction and have comprehensive knowhow of the pressure equipment directive. For control, testing KASAG offers a wide range of non-destructive testing methods. Please get in touch with us, and our KASAG experts will be glad to offer you expertise.

Request for a quote

KASAG SWISS AG

Switzerland

For new constructions, reconstructions, production expansions, we offer comprehensive services in pipeline construction and assembly for the regional food industry, in combination with our special apparatuses construction.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

KASAG SWISS AG

Switzerland

The KASAG glove box is used for handling and controlling in sterile processing. The glove box with introducer sheath is equipped with a vibrating sieve and is used when powdery products are filled into bags. The KASAG bag sterilising gassing chamber is used to ensure sterile sealing of products in bags. For that, air is extracted (vacuum) and subsequently swapped with nitrogen. The equipment complies with the strictest hygienic regulations. The mounting can be easily adjusted to the size of the bag.

Request for a quote

KASAG SWISS AG

Switzerland

The KASAG sterile containers, mixing tanks are used for preparing and mixing of products in the food industry. The container is equipped with a mixing device and jacket for heating and cooling. The entire system is built on a frame with a control unit and weighing cells.

Request for a quote

KASAG SWISS AG

Switzerland

Glucose container with fittings for the preparation of glucose (grape sugar) The mobile KASAG glucose container is vacuum-tight and provided with a level detector and pump. Dough container with shredder for the baking industry The dough container with shredder is especially made for the sponge cake industry.

Request for a quote

KASAG SWISS AG

Switzerland

Heating system for jams and marmalade The KASAG heating system for jams is used at industrial baking lines for preparing jams and marmalade. Jams or marmalade are conveyed with a pump via heated pipes. Static mixers ensure excellent heat transmission and very short process times. Tempering unit for chocolate for chocolate The KASAG tempering unit is used for heating, cooling, maintaining the consistency of the chocolate and for optimising production processes with chocolate.

Request for a quote

KASAG SWISS AG

Switzerland

Fat melting systems The KASAG fat melting system are compact systems for melting fat blocks from palm kernel fat, palm oil fat, coconut fat and concentrated butter. The liquid grease thereby gained is kept in the collecting tray at a specified temperature to be used in the respective production process. Size and design are determined by KASAG according to the requirements of the customer. Fat oil station KASAG fat oil station is an extension of the fat melter and is used to mix the ingredients into the liquid fat. The plants are installed on a base frame with levelling feet. All built components are ready for connection. The hot-water treatment and regulation is conducted via a tempering unit or connection to an existing hot-water network.

Request for a quoteResults for

Mechanical engineering - custom work - Import exportNumber of results

23 ProductsCountries

Company type