- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- tubes filling

Results for

Tubes filling - Import export

ALMA

Italy

We can fill tubes from 10 ml to 200 ml and apply the batch code on the product. foundation, primers, creams, body lotion, body wash

Request for a quote

MONGIN

France

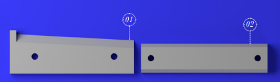

Cutting after tubes filling N°1 - Blade N°2 - Counter blad

Request for a quote

MONGIN

France

CUTTING AFTER TUBES FILLING TYPE OF MACHINES : UNIPAC, TONAZZI, KALIX, AXIOMATIC, ... On your tube fillers lines, once tubes filled and sealed, they are cut using a knife and a counter knife. N°1 Counter knife UNIPAC N°2 Knife UNIPAC N°3 Moving blade TONAZZI N°4 Fixed knife TONAZZI N°5 AXIOMATIC cutting die

Request for a quote

TECNOCOSMETICA - COSMETIC PRODUCTS MANUFACTURER

Portugal

Tecnocosmética has automatic filling lines for liquids and pastes with a capacity of approximately 10,000 units per day. Tecnocosmética has automatic lines for filling plastic and metal tubes with a capacity of approximately 20,000 units per day.

Request for a quote

PEEKCHINA CO., LTD.

China

ARKPEEK-GF30: 30% Glass Fiber + 70% PEEK Glass filled PEEK exhibits increased mechanical strength and high rigidity. Improved creep strength and dimensional stability are achieved by this glass filled PEEK. These properties make this material suitable for use in parts which are exposed to high static loads over long periods in high temperature conditions.

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

Easy to install, simple to operate and inexpensive to maintain For different flavor liquids only change the tubes high filling accuracy for small dosing liquid, from 1ml to 100ml is the best filling range if consider both the filling accuracy and speed Servo motor driven, easy adjustable filling volume,more working efficiently

Request for a quote

WACHSFABRIK SEGEBERG GMBH

Germany

We offer you the filling of your products With our production technology, we are able to meet almost all requirements and have appropriate filling facilities for: Tubes, bottles, cans, jars, canisters, barrels, pails, containers (including IBCs) Take advantage of our expertise in the filling of a wide variety of products. We react quickly, flexibly and precisely to changing requirements with well-organised processing times and reliable scheduling.

Request for a quote

PEKU FOLIEN GMBH

Germany

Tubular films are used when your products are not packed into ready-made bags, but the tube film is filled and sealed during the process of packaging. Together with important producers of packaging machines, PEKU Folien is developing the perfect tube for your application. From the very beginning, your packaging machines will run at a constantly high frequency. For our production of tubular film, we only use high-quality resins from leading manufacturers. Any questions concerning our tubular films? We look forward to your inquiry by mail or by phone: +49 (0)9181/2960-0!

Request for a quote

LEBEN-DÄMPFUNGSTECHNIK GMBH

Germany

The preferred field of application for the (gas) hydraulic industrial buffer (COMPENSER®) of the S-series is in the medium to heavy engineering industry sector. As a heavy duty shock absorber it is used in large crane systems (e.g. harbour crane, shipyard crane or container crane), metallurgical plants, rolling mills, loading systems or as end stop integrated in a rail buffer stop. Design & Function: The gas-filled inner tube 2 enters the outer tube 9. The damping medium flows from the pressure chamber 6 through the throttle orifices 8 of the metering tube 7 into the volume balance chamber 5. The separating piston 4 simultaneously moves in the direction of the impact cap 1 and compresses the nitrogen gas filling. In the gas space 3, the energy is stored which is required for the reset of the inner tube. When the inner tube 2 returns to the initial position, the separating piston 4 moves in the opposite direction and presses the damping medium back into the pressure chamber 6.

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

Peristaltic pump liquid filling machine is one type of liquid filler which adapts the positive displacement pump as a dosing system.The pumps use the principle of peristalsis as the basis for their design. It is mostly application for filling small dosing liquid, for it is high GMP standard,and only the inner bore of the tube touches the fluid, it eliminate the risk of the pump contaminating the fluid, or the fluid contaminating the pump, so most of the phamarcy factories adapt this equipment for filling their liquid into small vial, such as eye drops, ear drops,phamarceuticals liquids, also some top cosmetics ,biology liquid also filling by the peristaltic pump. Feature Easy to install, simple to operate and inexpensive to maintain For different flavor liquids only change the tubes high filling accuracy for small dosing liquid, from 1ml to 100ml is the best filling range if consider both the filling accuracy and speed Servo motor driven, easy adjustable filling volume.

Request for a quote

VISCOTEC PUMPEN- U. DOSIERTECHNIK GMBH

Germany

The ViscoTec dosing and filling pump RD-Hygiene for food and cosmetics is a volumetric pump based on the continuous piston principle. It is ideally suited for discontinuous or continuous pulsation-free dosing of viscous, structure-sensitive and solids-laden media. Thanks to the high-quality ViscoTec dispensers, high-precision dosing applications can be realized in the food and cosmetics sector. The systems are used e.g. in the bakery and confectionery sector for decoration. Typical doses are icing or fondant, but also fillings such as vanilla or chocolate cream. Your advantages: - Specially adapted filling tubes for a wide variety of filling applications - Application and dosing in automated systems - Low to high viscosity as well as abrasive, shear-sensitive or lumpy media - hot and cold filling - Optimum results for CIP/SIP (Cleaning in Place/Sterilisation in Place) cleaning

Request for a quote

RONIX GMBH

Germany

Spirit levels are tools commonly used in construction, woodworking, and other fields where accurate leveling is important. They consist of a straight bar or tube filled with liquid (usually alcohol) and a bubble. When the bubble is centered between two lines marked on the tube, it indicates that the surface being measured is level. The Ronix RH-9417 spirit level is simple and easy to use, requiring no batteries or AC power. It is compact and lightweight, making it easy to carry and use in tight spaces. It also features level bubbles that accurately measure horizontal, vertical, and 45° tilt angles. The level is durable and impact resistant due to its aluminum housing. Plus, this practical hand tool is easy to read with clear, visible level bubbles.

Request for a quote

INGAS LLC

Ukraine

Formula: He General Description: monoatomic, non-toxic, chemically inert gas, odorless, colorless and tasteless Gas purity and content of its controlled impurities(vol.%, ppmv) Brand 4.0 99,99% Brand 4.5 99,995% Brand 5.0 99,999% Brand 6.0 99,9999% Areas of use: Metallurgy - as an inert shielding gas for smelting pure metals; Welding industry - as an inert medium in arc welding; Food industry - as a packaging gas for food preservation; For gas-filled aircraft and weather probes and balloons in the entertainment industry; Breathing mixtures for deep-sea diving; Advertising - for filling gas discharge tubes; Nuclear power - as a coolant; Gas chromatography; Helium-neon lasers. Brand 4.0 Helium (He) 99.99% Neon Ne ⩽90.0 ppmv Nitrogen N2 ⩽20.0 ppmv Oxygen + Argon O₂+Ar ⩽6.0 ppmv Hydrogen H2 ⩽25.0 ppmv Amount of hydrocarbons ΣCₙHₘ ⩽5.0 ppmv Carbon monoxide + Carbon dioxide CO+CO₂ ⩽10.0 ppmv Moisture H2O ⩽20.0 ppmv

Request for a quote

RAYUEN PACKAGING CO.,LIMITED

China

simple but chic style cylinder round tube, features at bottom filling, made by full recyclable plastic PP and ABS material, can be used as ideal packaging solutions for filling lip balm and lipstick, available for wholesale and custom packaging design for private brands.

Request for a quote

REA ELEKTRONIK GMBH

Germany

CO2 laser marking systems are part of the gas laser group: the laser beam is generated in an enclosed laser tube which is filled with carbon dioxide. The REA JET CL is suitable for the marking of packaging, glass, wood, plastics, PVC, anodized aluminum, the color removal on surfaces as well as direct marking of foods. In the creation of texts, graphics and characters there is complete freedom of design. Applications — Marking of glass, wood, rubber, engraving and color change marking of plastics (automotive, medicine, consumer goods) — Coding of cardboard boxes and outer packaging (e.g. in the pharmaceutical, cosmetic and food sectors) — Coated substrates (e.g. anodized aluminum) — Direct marking of foodstuffs — Laser color change marking — Color mirror engraving

Request for a quote

DELEYER FOOD

Netherlands

The soft version has the best shine, and are ready to use by warming the tube up in some warm water for only a short period. This version is best suitable for pancakes, desserts and cakes. The filling stays soft when you are done decorating, but will harden a bit in de refrigerator.

Request for a quote

DELEYER FOOD

Netherlands

The hard version contains a chocolate look alike. It takes longer before they are ready to use, but they harden after you made the decoration. This version is best suitable for decorating cookies and chocolates. Also you can make pickable chocolate decorations with this version.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

POLY-CLIP SYSTEM GMBH & CO. KG

Germany

Gain in efficiency – sealing and clipping with one machine The TSCA Automatic Sealing/Clipping Machine processes flat film from a roll into a ready-to-fill tube which is securely closed by the integral clipping unit. All commonly used films, coated or uncoated, as well as laminates can be processed. The film rolls used can be up to 3,000 metres long. Subject to technical modifications.

Request for a quote

PENGG KABEL GMBH

Austria

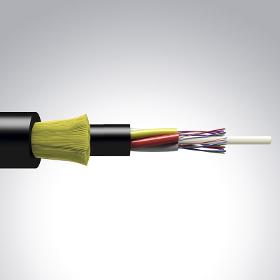

Fiber optic cables with this design consist of a central, jelly-filled loose tube and are available with a maximum of 24 fibers.

Request for a quote

PENGG KABEL GMBH

Austria

LOOSE TUBE CONSTRUCTION, JELLY FILLED CABLE CORE, WATERTIGHT, RODENT PROTECTION, ALUMINIUM-PE-COMPOSITE-LAYER SHEATH Suited for outdoor use - for fixed laying in cable ducts, conduits or direct burial.

Request for a quote

PENGG KABEL GMBH

Austria

LOOSE TUBE CONSTRUCTION, JELLY FILLED CABLE CORE, WATERTIGHT, RODENT PROTECTION, ALUMINIUM-PE-COMPOSITE-LAYER SHEATH Suited for outdoor use - for fixed laying in cable ducts, conduits or direct burial

Request for a quote

HILGENBERG GMBH

Germany

We have developed special glass cannulas that greatly simplify filling our test tubes with liquid samples. Our thinnest cannula has a diameter of less than 0,1 mm. This enables even the finest test tubes to be filled without problems. A standard Luer connection enables the cannula to be fitted to conventional one-way syringes or microliter syringes. Our filling needles are made of borosilicate glass, whereby the shaft consists of plastic into which the needle is bonded. Various diameters are available. Syringe needles for filling Mark-tubes with liquids

Request for a quote

HILGENBERG GMBH

Germany

Our sample tubes are used for X-ray fine structure analysis of single crystals, powder specimens, and liquid crystals. Based on the low absorption through the glass the extremely thin-walled capillaries allow the analysis of small samples sealed in a gas and moisture proof environment. According to the Debye-Scherrer method or in gerneral SAXS (small angle x-Ray scattering) and WAXS (wide angle x-Ray scattering) measurements can be made with our mark tubes, which are also named XRD capillaries. The wall thickness of only about 10 µm makes the tubes particularly suitable for high-precision measurements. Thanks to the wide funnel at the upper end, samples can be filled easily into tubes even with the smallest diameter. Absorption coefficients Our test tubes are manufactured of various types of glass with different linear absorption coefficients, so that a suitable tube can be found for practically every application. High quality standards are maintained during production, which...

Request for a quote

SERVOLIFT GMBH

Germany

A system is only complete when they also fulfill product transfer to interfaces. Thus the specified OEB level is supplied from SERVOLIFT with valves, split valve systems, feed systems, funnels, discharging aids, filling and discharge tubes, etc., corresponding to the containers and handling equipment. The solutions meet the requirements of cGMP and the FDA. Whether protecting the products against their environment, or protecting employees from the product, SERVOLIFT always has the solution, with over 40 years’ experience in the field. Low-dust or dust-free Technical description DECELERATOR: Product transfer from one process to another are often vertical in the pharmaceutical and chemical industry. The feed must then be carried out for the most part over a given vertical distance. Controlled product flow using regulated compressed air transfers the product without segregation at the adapted fall speed in vertical product transfer systems. Segregation-free, controlled product...

Request for a quote

EACTECH®

Portugal

The filling equipment for delicatessen that combines speed and efficiency The Filler EVC-2000 is the equipment you will want as an ally for filling in delicatessen. Chorizo, fresh sausage, sausage, salami, etc. It combines a 10-fin motor feeding system, reducing losses and preventing stains and bubble formation, while controlling the exact size of the portions. A filling solution for optimal results on your production line. The HF-250 hamburger maker is state-of-the-art equipment to produce a wide range of hamburger shapes and sizes. The mold filling system is automatic, guaranteeing uniformity and quality of the final product. Speed and pressure configured on touch panel Greater efficiency Extra income Touchscreen system Control panel with microprocessor Final product quality guaranteed 100%

Request for a quote

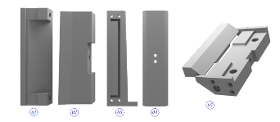

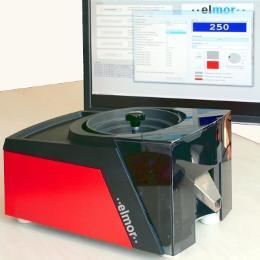

ELMOR

Switzerland

The PC controlled, high sensitive elmor C3 Seed counter is preferably used in scientific counting tasks in laboratories Universities, research and breeding projects or in seed quality control etc. Parts that can be processed with the C3 seed counter are, for example: Dust fine plant seeds such as Arabidopsis thaliana or Begonia semperflorens Vegetable seeds, grains or seeds of ornamental plants Insects, pupae and eggs Small mechanical parts Pharmaceuticals Semiconductor chips etc. The C3 Counter is controlled solely via PC. Thus new solutions for the ever growing demands of the customers are possible. All settings and the results of all operations are logged and saved . This is an essential prerequisite for quality control and traceability of test results. The parts that can be counted with the C3 seed counter can be extremely small and irregularly shaped. Thus they are very difficult to handle manually. Dosing these parts with scales is often flawed or impossible. Therefore the use of the of C3 opens new options, since e.g. smallest parts in the sub-milligram range can be dosed faster and more accurately by counting than weighing the pieces. With additional software modules also further evaluations can be performed. These are currently: direct 1000 grain weight determination and the grain size analysis. Technical data Counts Parts from 0.1 to 18mm in diameter For spheres of 2mm diameter: Counting rate: 50’000 parts per hour Typical counting error: less than 1/1000 Runs under Windows XP/7/8.1 Free Serial Port (RS232) or USB needed Software included Totalizer Preset Counter Additional software available: Direct determination of the 1000 Kernel Weight Analysis of the size of the counted particles: Particle Size Analysis Conveyor bowls The parts to be counted are transported in a vibrating conveyor and are singularised by means of a sorting element. Both the conveyor bowl as well as the sorting element can be selected among different variants , depending on the properties of the product to be counted. A) Standard conveyor bowl made of anodised Aluminium with universal – sorting element FS0. FS0 is manually adjustable for all part sizes from 0.1 to 18 mm in diameter. B) Special sorting elements instead of FS0: FS1, manually adjustable, optimised for cereals, rice, paddy and products of similar shape and size FS2: manually adjustable, optimised for corn, soybeans, peas, beans and products with similar shape and size FS3: fine-drive adjustable in height and width, for very flat seeds or flat mechanical parts with the following dimensions: width: 0.5 to 10 mm, height: 0.5 – 8 mm, maximum length: 20 mm C) Special conveyor bowl with additional lateral opening for mechanically eliminating of accompanying substances, suitable for corn, cereals, soybean, paddy, etc. The height of this opening can be adjusted from 0 to 5 mm and allows unwanted accompanying substances laterally be sorted out. Not suitable for parts smaller than 1 mm in diameter. Can be used with sorting elements FS0, FS1, FS2, or FS3 combined. D) To meet the needs of various industries, the conveyor bowls can be made of other materials . These bowls are for example extremely impact resistant or correspond to the rules of the FDA, etc. Such trays can be made from various basic materials like Titanium, PEEK, Polyamide and others. E) The standard aluminum bowls can be treated or coated in order to satisfy specific requirements. With increased mechanical stress or when in contact with food, the surface can be hard anodized. A hard coating of nickel has a high surface hardness and is FDA approved, Polyurethane (PU) coating permits rapid transport of heavy mechanical parts and prevents noise and wear. Again, FDA approved materials can be used. F) Feeder Bowl with vertical outlet: Short cycle times are possible, as the seeds leave the bowl after a short run time. Advantageous when many different lots must be processed, often used for the fast 1000 grain weight measurement. Used for seeds which can be easily singularised like Crop, Soy, Corn, Canola etc. The seeds should have a diameter of 2 mm or more. Volume 0.8 litres, or about 2500 kernels of Corn. Automatic 1000 Grain Weight Measurement By means of an additional software module, an electronic balance and a special frame, the precision counter C3 can be used for the direct determination of the 1000 kernel weight of a sample. Both the C3 as well as a balance are connected with the control computer. A freely selectable quantity is counted and falls on the scale pan. At the end of the counting operation the weight of the sample and the corresponding number of particles is transmitted automatically to the PC, where the 1000 kernel weight is calculated. With the conventional 1000 grain weight determination, the number of items and the weight must be entered manually into a calculating machine. In many cases, exactly 500 or 1000 kernels are counted and weighed; and then the 1000 grain weight can be determined without no arithmetic exercise, but the danger exists that the result is falsified by separation effects during the operation of the vibrating conveyor (grain size selection). With the simultaneously determination of seed quantity and weight all potentially faulted manual inputs are eliminated. But most important is that in this procedure the particle size selection is impossible. If necessary the result can be printed out or processed electronically. Further the danger of the grain size selection can completely be avoided. Particle Size Analyzer The precision seed counter C3 can be used as particle size analyzer to determine the particle size distribution of a given sample by means of a special software module. The size of the singularised and free falling parts is measured in one dimension with a resolution of some 1/100 mm. This measurement is intended primarily to compare different samples qualitatively. With spherical parts the measurements give also quantitative information. The measured values of the particle size analyzer are stored as txt file. This makes it possible to further process the raw data individually by means of appropriate standard software. Filling Carousel The C3 parts counter can be combined with the elmor 780 carousel filler. The carousel filler allows semi automatic, to a large extent unsupervised filling of vials, tubes, small containers as well as bags from paper, glassine or composite material. Feeding Conveyor elmor 610 Feeding conveyor and storage hopper for automatic refilling of the conveyor bowls of our counting machines C1, C3 or CX elmor Green Design Our label for: high energy efficiency longevity no standby power loss most components may be recycled production without solvents, ROHS conformity Click here to add your own text Click here to add your own text

Request for a quote

ELMOR

Switzerland

Counting machine elmor C1: accessories and variants Conveyor bowls The parts to be counted with the elmor C1 counting machine are transported in a vibrating conveyor and are singularised by means of a sorting element. Both the conveyor bowl as well as the sorting element can be selected among different variants , depending on the properties of the product to be counted. A) Standard conveyor bowl made of anodised Aluminium with universal – sorting element FS0. FS0 is manually adjustable for all part sizes from 0.1 to 18 mm in diameter. B) Special sorting elements instead of FS0: FS1, manually adjustable, optimised for cereals, rice, paddy and products of similar shape and size FS2: manually adjustable, optimised for corn, soybeans, peas, beans and products with similar shape and size FS3: fine-drive adjustable in height and width, for very flat seeds or flat mechanical parts with the following dimensions: width: 0.5 to 10 mm, height: 0.5 – 8 mm, maximum length: 20 mm C) Special conveyor bowl with additional lateral opening for mechanically eliminating of accompanying substances, suitable for corn, cereals, soybean, paddy, etc. The height of this opening can be adjusted from 0 to 5 mm and allows unwanted accompanying substances laterally be sorted out. Not suitable for parts smaller than 1 mm in diameter. Can be used with sorting elements FS0, FS1, FS2, or FS3 combined. D) To meet the needs of various industries, the conveyor bowls can be made of other materials . These bowls are for example extremely impact resistant or correspond to the rules of the FDA, etc. Such trays can be made from various basic materials like Titanium, PEEK, Polyamide and others. E) The standard aluminum bowls can be treated or coated in order to satisfy specific requirements. With increased mechanical stress or when in contact with food, the surface can be hard anodized. A hard coating of nickel has a high surface hardness and is FDA approved, Polyurethane (PU) coating permits rapid transport of heavy mechanical parts and prevents noise and wear. Again, FDA approved materials can be used. F) Feeder Bowl with vertical outlet: Short cycle times are possible, as the seeds leave the bowl after a short run time. Advantageous when many different lots must be processed, often used for the fast 1000 grain weight measurement. Used for seeds which can be easily singularised like Crop, Soy, Corn, Canola etc. The seeds should have a diameter of 2 mm or more. Volume 0.8 litres, or about 2500 kernels of Corn. Dual Product Outlet The dual product outlet can increase the productivity in Preset Mode (= repetitive batch counting). Each time when a batch is counted, the outlet switches to the other side and the counter restarts automatically. The dual discharge chute is intended to be used for counting crop seeds or corn, which are filled directly into bags, but can also be used for other seeds with 1mm diameter or more. Automatic Seed Weight Sorter Each single seed of a lot is automatically placed on a scale. The Automatic Seed Weight Sorter measures the weight of each seed and compares it with one or several limits. According to the result of this comparison, the weighed seed is then transferred into two or more containers. So the parts can weighed and sorted either into good and bad parts or into several weight classes. Filling Carousel The C1 parts counter can be combined with the elmor 780 carousel filler. The carousel filler allows semi automatic, to a large extent unsupervised filling of vials, tubes, small containers as well as bags from paper, glassine or composite material. Filling adapter Adapter for small containers, bottles, laboratory tubes etc. This adapter allows dustfine and costly parts to be filled directly into containers. The C1 seed counter can be started only when a container is present.The filling adapters are manufactured individually on request. Dust Cover If specific small parts are processed, a dust cover can be of advantage. This is for example the case with pharmaceutical components, implants or with parts that need to be processed in a protective atmosphere. In this case, nitrogen or other gases or may be introduced through the dust cover. Ionizer When transporting small parts in the vibrating conveyor bowl there is a risk that the parts can become electrostatically charged. The correct separation of the charged parts becomes difficult. With an ionizer, the charged parts can be neutralised, shortly before leaving the bowl, in the region of the sorting element. The ionizer used in elmor C1 seed counter is manufactured by a specialized company, which is represented worldwide. The head of the ionizer is attached inside of a dust cover. Receipt Printer for Seed Counter elmor C1 The result of each completed count is printed automatically. The printing is done in plain text and bar code. During sample preparation or inventory counts many customers have expressed a wish to be able to print the determined number immediately. This can be done with this new accessories for the C1 counter. Faulty manual recordings are obsolete. Technical data: Paper: standard thermopaper rolls, 80mm width. Internal cutter, label length 64mm Barcode: Code 128 (International Standard ISO/IEC 15417), other codes on request Power supply: 100 – 240V, 50/60Hz The C1 seed counter must be equipped with an elmor printer interface board Feeding Conveyor elmor 610 Feeding conveyor and storage hopper for automatic refilling of the conveyor bowls of the counting machines elmor C1, C3 or CX Intermediate storage container of counted parts When a seed counter is combined with a packaging machine, it may be advantageous to add a container for synchronization therebetween. When the counting operation has finished and the packing machine is ready, a discharge flap is opened briefly, so that the content of the container is discharged into the packaging machine. Then the flap closes and the counting machine begins with a new operation. As a result, the waiting time that would be needed before a packaging machine is ready for the next lot can be greatly reduced, allowing a shorter cycle time. Depending on the task different volumes can be realized.

Request for a quote

JSC MOSKABEL-FUJIKURA

Russia

Optical aerial self-supporting cable, dielectric, with a central strength member made of FRP rod; tubes with up to 24 optical fibers and (if necessary filling dummy tubes) are stranded around the strength member; with a strength member of aramid threads, with single or double PE sheath. Operational temperature of the cable is from -60°С to 70° С. Minimum temperature for installation is -30°С.

Request for a quote

JSC MOSKABEL-FUJIKURA

Russia

Distribution optical cable with a central strength member made of FRP rod in PE sheath; around it are stranded tubes containing up to 24 optical fibers each, filling dummy tubes (if necessary), insulated copper conductors, with intermediate PE sheath, with water-blocking tape, laminated aluminum PE tape; with an armor made of steel corrugated tape and outer PE sheath. Operational temperature of the cable is from -60°С to 70°С. Minimum temperature for installation is -30°С.

Request for a quoteResults for

Tubes filling - Import exportNumber of results

39 ProductsCountries

Company type

Category

- Cables & Networks (6)

- Bottling and filling - machinery and equipment (4)

- Cosmetics (4)

- Copper wires and cables (3)

- Aluminium wires and cables (1)

- Cylinders, hydraulic (1)

- Dosing - machines and equipment (1)

- Electric and electronic components - machines for manufacturing (1)

- Films, plastic (1)

- Food Processing (1)

- Food packaging (1)

- Gas mixtures (1)

- Hoses, pipes and tubes - plastic (1)

- Polymers (1)

- Tools, pneumatic (1)