- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- industrial machinery

Results for

Industrial machinery - Import export

RUSSELL FINEX LTD

United Kingdom

Vibratory batch sieving machines to remove contamination from small batches of products, improving product quality and reducing downtime. For more details, please send us a message or click on the website link.

Request for a quote

RUSSELL FINEX LTD

United Kingdom

Pneumatic sieving equipment to remove oversize contamination within blowing lines. For more details, please send us a message or click on the website link.

Request for a quote

RUSSELL FINEX LTD

United Kingdom

Bag tipping platform for hand fed raw ingredients from bags. For more details, please send us a message or click on the website link.

Request for a quote

RUSSELL FINEX LTD

United Kingdom

Vacuum conveying sieve for air-tight sieving and conveying of fine and dusty materials in one operation to improve production capacity. For more details, please send us a message or click on the website link.

Request for a quote

RUSSELL FINEX LTD

United Kingdom

Vibratory sifters for high containment applications such as pharmaceutical powders to improve product quality and safeguard operators health and safety. For more details, please send us a message or click on the website link.

Request for a quote

THE FUME CUPBOARD COMPANY LTD

United Kingdom

Movex™ Extraction arms The Fume Cupboard Company are authorised Movex™ extraction arm installer supplying, installing, and maintaining Movex™ bench and ceiling mounted fume extraction arm systems. Independently sourcing a diverse product range covering all working environments where hazardous dust and fumes form part of the working process. Local extraction is established in direct connection to the working process. This is done to remove the hazardous vapors and substances as closely to the source as possible before they are spread into the room.

Request for a quote

THE FUME CUPBOARD COMPANY LTD

United Kingdom

Ductwork Design & Installation - Onsite Ductwork Fabrication A Fume Cupboard Extraction System. should be designed, installed to run efficiently, safely and with the minimum of noise levels. To achieve these requirements all our extract and duct work systems are designed, installed, and commissioned to meet the requirements of H.V.A.C. DW154 (Plastic duct work specification), and B.S. E.N. 14175. Extract systems to serve educational style fume cupboards will meet standards set out in Building Bulletin 88 or B.S. E.N. 14175. At the fume cupboard company, we try and hot air weld as much of the ductwork as possible this prevents leakage and sustains the integrity of the joints for the duration of its life. We provide a variety of different duct materials these consist of: Chemically resistant P.V.C | Polypropylene | Galvanized Metal. For extra protection we can also make glass reinforced plastic (GRP) and fire retardant coating for this duct work.

Request for a quote

THE FUME CUPBOARD COMPANY LTD

United Kingdom

Educational & Commercial - Fume Extraction Systems Our COSHH Test engineers are fully qualified to BOHS P601 (Commissioning and Thorough Examination of LEV Systems). We ensure all surveys are carried out in accordance with the COSHH regulations 7 & 9, following Health & Safety guidance (HSG258). The Local Exhaust Ventilation test is designed to determine the efficiency and integrity of an extraction system. It requires the engineer to gain quantitative measurements by using airflow instruments and qualitative assessments with smoke tests and a dust lamp. Engineers analyse these results and use invaluable expertise to identify design flaws, defects and maintenance issues that might affect the performance of an LEV system following completion of LEV Testing. Upon completion of an onsite COSHH Safety test a detailed report is produced that contains the findings of the survey and any comments and recommendations that are relevant, including remedial work required.

Request for a quote

THE FUME CUPBOARD COMPANY LTD

United Kingdom

The Airflow 8 Cupboard is best suited for Industrial and Commercial situations. These Ducted Fume Cupboards are available in standard widths of 1200mm, 1500mm, 1800mm and 2000mm. Compliant with: Building Bulletin 88 (Rev G9.) Designed and manufactured in accordance with Energy Efficient Design and Operation of Fume Cupboards Guide 320. Meets BREAMM Hea 17 and Ene 11 compliance. Please note a suitable extraction system will be required for the fume cupboard to operate correctly, the extract system should be designed and installed to meet the requirements of D.W. 154 and Building Bulletin 88. The Fume Cupboard Company can offer a full turnkey solution The Airflow 8 Fume Cupboard range include :- Standard Bench Mount Walk-in Double Fronted Double Fronted Walk-in Slim Profile Sides

Request for a quote

THE FUME CUPBOARD COMPANY LTD

United Kingdom

Ductless Industrial Fume Hoods Purair RX Ductless Balance Enclosures. is a Class I enclosure that meets USP 795 requirements for non-sterile compounding procedures. The Purair RX is designed to protect the user and the environment from hazardous powders and particulates generated on the work surface. That the heart of the Purair product line is innovative ductless technology that creates a safe work environment in a wide variety of applications utilizing balance enclosures, compounding, powder mixing, and powder weighing.

Request for a quote

THE FUME CUPBOARD COMPANY LTD

United Kingdom

Airflow® Horizontal Laminar Flow Hoods. are a series of high efficiency products designed to protect equipment and other contents of the work zone from particulates, for applications sensitive to such contamination. The series includes Vertical Laminar Flow Fume hood (VLF) and Horizontal Laminar Flow Fume hood (HLF) and is ideally suited for use with non-hazardous contaminants and when flexible access to the equipment in the work zone is desired. At the heart of the Airflow® Laminar Flow Hood product line is the Air Science Multiplex™ ULPA Filtration Technology that creates a clean work environment over a wide range of applications. This unit is not recommended for preparation rooms where the fume cupboards are used for long periods of time as this will degrade the carbon filter faster than expected.

Request for a quote

THE FUME CUPBOARD COMPANY LTD

United Kingdom

Airflow® Vertical Laminar Flow Hoods. are a series of high efficiency products designed to protect equipment and other contents of the work zone from particulates, for applications sensitive to such contamination. The series includes Vertical Laminar Flow Fume hood (VLF) and Horizontal Laminar Flow Fume hood (HLF) and is ideally suited for use with non-hazardous contaminants and when flexible access to the equipment in the work zone is desired. At the heart of the Airflow® Laminar Flow Hood product line is the Air Science Multiplex™ ULPA Filtration Technology that creates a clean work environment over a wide range of applications. This unit is not recommended for preparation rooms where the fume cupboards are used for long periods of time as this will degrade the carbon filter faster than expected.

Request for a quote

COLLETT & SONS LTD

United Kingdom

> Click on the "WEBSITE" link for more > Our dedicated Team of Jacking & Skidding Engineers have the knowledge and expertise required for machinery extraction and the relocation of industrial cargoes in confined and restricted environments. Utilising our specialist jacking & skidding equipment our Heavy Lift Team can ensure that no matter what the environment we can safely and securely undertake the heavy transport, extraction and load positioning of machinery & industrial cargoes. In restricted environments crane hire is not always a suitable option. Utilising our specialist hydraulic jacking & skidding systems Collett Engineers have the ideal solution for these confined spaces, providing a lifting, extraction and load positioning service in areas where traditional transport arrangements may not be a suitable option.

Request for a quote

SELMACH MACHINERY LTD

United Kingdom

Our very own Morgan Rushworth range combine with the Ajan plasma and Hypertherm plasma to deliver the very best plasma cutting machinery our industry has to offer. We pride ourselves in being to offer a wide range of sheet and plate metal machinery to suit all of your fabrication requirements. With years of experience and knowledge of the industry and an in-depth understanding of a wide range of applications, our sales team strive to recommend the most suitable machinery for your specific requirement

Request for a quote

CRANAGE EMC & SAFETY

United Kingdom

Cranage has multiple testing facilities, accredited by UKAS, to test for EMC as well as radio communication, electrical safety, mechanical and environmental performance. Our Engineers have experience of testing hundreds of different products, including wheelchairs, ECG Monitors, hair styling appliances, household appliances, PCB's, Vacuums, Information point systems, Electric gates, metering systems. We can test and evaluate within the following sectors- Lab and Scientific equipment, Medical Devices, Household appliances, IT equipment, Industrial and Machinery Equipment, Lighting, Electrical Fittings, Road and Rail equipment, Security, Fire and Smoke equipment, Mobility aids and Stairlifts. If your equipment is large or in-situ we can also offer EMC testing at your premises. Our pre-compliance testing is used to identify potential issues during product development.

Request for a quote

DRALLIM INDUSTRIES LIMITED

United Kingdom

The Rotary Selector Valve or RSV, is a small bore multiport, multibank rotary poppet system suitable at pressures ranging –1 +10 Bar, Fluid Temperature 85°C (185°F) . It is a relatively simple & therefore extremely reliable unit, based on a modular design & as such configurable for a multitude of applications. It is custom built from stock parts. The body is manufactured in brass or stainless steel, both having stainless spindles & they can have stems and seals in differing materials to suit the media being used. Each bank of the valve is pneumatically independent but linked by a common central spindle, enabling separate air paths to be controlled concurrently; each output is effectively a valve. The RSV (once also known as the PIV or Pneumatic Interlok Valve) can incorporate an integral electrical rotary switch which allows fluid & electrical circuits to be controlled simultaneously or can be used simply to provide positional indication remotely at the control centre.

Request for a quote

DALROAD NORSLO

United Kingdom

LS Industrial Systems low voltage inverter drives compliant with international European Machinery standards. LS Industrial System IC5 Inverter Drive LS Industrial Systems iS7 Inverter Drive LS Industrial Systems S100 Inverter Drive LS Industrial Systems H100 Inverter Drive

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

BIOPHARMA GROUP

United Kingdom

Rocket Synergy 4D is for drying single large volumes of solvent, from a few litres up to approximately 100 litres. The system can also be used for a single batch of up to 5 litres. Rocket Synergy 4D provides fast, safe evaporation for solvents with a boiling point of up to 165°C (DMF) and can easily dry aqueous samples. Automatic evaporation of volumes up to 100 litres Eliminates bumping or foaming Easy vessel manipulation with no glassware to handle Safe, easy product recovery and system cleaning

Request for a quote

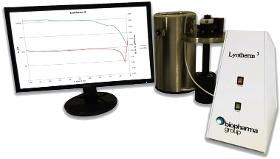

BIOPHARMA GROUP

United Kingdom

Frozen state solutions are a critical product stage or end product in a variety of industries, including freeze drying, pharmaceuticals, food storage and biotech. The Lyotherm3 combines electrical and thermal techniques. This unique dual analysis adds a new dimension to the data of this critical stage. Impedance Analysis (Zsinφ) is a fixed frequency dielectric analysis providing an indication of the sample tracks molecular mobility, including events not picked up by thermal methods like DTA or DSC Differential Thermal Analysis (DTA) measures the difference in temperature between a sample and a reference, highlighting exothermic and endothermic events e.g. crystallisation, eutectic melting and glass transitions Combining DTA and Impedance analysis means Lyotherm is more sensitive to changes within the frozen structure than other exclusively thermal techniques.

Request for a quote

BIOPHARMA GROUP

United Kingdom

Kinematics & Controls Corporation’s compact modular powder filling systems have proved to be popular in environments where not only precise material dosing is required, but also in areas where companies seek to make the process more efficient, maximising potential product throughputs. Powder is picked up by vacuum and compacted to a constant density within a cylindrical fill chamber. It is subsequently dispensed by the application of low-level, positive-pressure air. The use of a pre-defined vacuum force, compressing the powder sample to a uniform/ even density is the key to achieving the high level of repeat dose accuracy. Cumbersome, time-consuming, hand-weighing is thus eliminated. A wide range of standard gun sizes and filters with various porosities are offered for use with the variety of powders and container sizes which the customer’s process might demand. A custom, 8-up, Micro-Well kit can also be specified, to streamline the filling of 96-cavity well plates.

Request for a quote

BIOPHARMA GROUP

United Kingdom

The Series 3 HT evaporator range from Genevac represents the ultimate in solvent removal technology. Genevac-014 A Solution for High Throughput Evaporation Genevac HT series evaporators are the ideal solution for parallel evaporation bottlenecks in high throughput and production laboratories having high performance and high sample capacities. The unique design of the multi-layer rotor ensures efficient use of valuable laboratory bench space as well as high performance and high throughput evaporation. This proven design has now been updated with the latest version, the Series 3.

Request for a quote

BIOPHARMA GROUP

United Kingdom

The Emulsiflex range of high pressure homogenisers from Avestin are ideal for a wide range of applications, commonly use d within the pharmaceutical, biotechnology and fine chemicals industries. These include cell lysis, particle size reduction, nanoparticles, emulsions (emulsification), and liposome preparation. Additionally, it offers reliable, consistent processing at adjustable pressures of up to 45,000 psi, Both air-powered and electrically-powered systems are available, and options include filter/extruder attachments, temperature control mechanisms and automatic pressure control. The unique Emulsiflex design ensures that there are no ‘O’-rings or gaskets in the entire path of the product. This means less risk of contamination, easier cleaning and no leakage.

Request for a quote

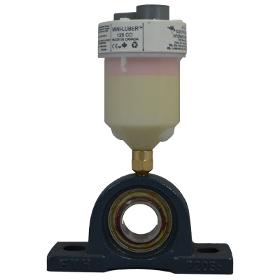

ATS ELECTRO-LUBE EUROPE

United Kingdom

The ATS Food Luber is an inert, waterproof automatic lubricator, designed for the food & beverage industry. With the widest operating temperature range of any electro-chemical lubricator, -40°C to + 55°C, the Food Luber is the most reliable & versatile food lubrication system, and suitable for a huge range of food, beverage, or pharmaceutical applications. Dust-proof, and submersible to 10m, it's the most perfect lubricator for bottling lines, mixing vessels, ovens or refrigeration. The positive pressure it creates at the lube point will eradicate contaminant and water ingress, significantly lowering breakdown occurrence and repair costs. Compatible with all grades of food lubricant, the Food Luber boasts the quality and reliability of any ATS Electro-Lube product, making it the smart choice for any operation where uptime and high productivity are crucial.

BRILLOPAK

United Kingdom

High specification automatic machines to dispense or stack crates and trays onto manual and automatic packing lines. Reliable 600mm x 400mm retail crates Complete pallet of accumulation FEATURES & BENEFITS: -Small Footprint. -Heavy Duty. Robust construction for 24/7 usage and reliability. -Reduced labour cost in preparing crates pre/post production line. -Reduced health and safety risk through repetitive handling of crates. -Consistent throughput speed increases overall packing efficiency. ** Click for more **

Request for a quote

BRILLOPAK

United Kingdom

Designed for 24/7 operation this machine dispenses pallets and accumulates a loaded pallet stack outside the cell. Can be floor loading or over conveyor. Up to 30 cases or crates per minute Small footprint Enhanced Safety Features FEATURES & BENEFITS: -Specialist Brillopak robot heads. Run multiple products with no tooling changeover. -No manual heavy lifting. -System automatically lifts pallet stacks from floor and places loaded pallet stack onto floor for use with hand trucks. -Simple to operate by unskilled staff. -Entire system built and fully tested in our factory. Delivered in 2 pieces for very fast commissioning on site. ** Click for more **

Request for a quote

BRILLOPAK

United Kingdom

The dual cell machine has a small footprint and is designed for cases, boxes, trays, and bags. Brillopak specialist end effectors will handle multiple case or bag sizes, as well as all current supermarket rigid/collapsible tray types without the need for tooling changeovers. Continuous palletising Multiple products and layer patterns Additional safety gate between cells FEATURES & BENEFITS: -Compact size. -Specialist Brillopak robot heads. Run multiple products with no tooling changeover. -Simple to operate by unskilled staff. -Easy to programme new patterns in-house. -Enhanced safety features. ** Click for more **

Request for a quote

BRILLOPAK

United Kingdom

Our Flexible Robotic Palletiser is the smallest footprint and is designed for cases, crates and bags. Multiple products Multiple patterns Easy to program FEATURES & BENEFITS: -Compact: Smallest palletiser for crates. -Specialist Brillopak robot heads. Run multiple products with no tooling changeover. -Simple to operate by unskilled staff. Select the product and press start. -Easy to maintain. Simple plug in, plug out of new parts. -Enhanced safety features. ** Click for more **

Request for a quote

BRILLOPAK

United Kingdom

An optimised semi-automatic packing machine that puts you back in control of pack line speed. Reduced Labour Cost - Semi Automatic Packing Machine Increased product throughput Minimised quality issues FEATURES & BENEFITS: -Increases line speed, semi automatic packing machine. -Ergonomically designed for optimal performance. -Handles crates or cardboard trays. -Minimises health risks associated with repetitive working. -Tray infeed at rear or system minimises clutter along the line. ** Click for more **

Request for a quote

BRILLOPAK

United Kingdom

The BRILLOPAK P160 Unipick provides high-speed, accurate but gentle packing of tray seal, flow wrap and VFFS products into trays, cases and boxes. Ideal for packing fruit and meat. Multiple products Multiple patterns Delicate product placement FEATURES & BENEFITS: -Flexibility of operation. Single pick means one system can support multiple product types with multiple patterns. -Extreme accuracy of placement into crate ensures first class presentation on supermarket shelf. -Delicate handling: Due to single pick, individual products are placed gently and accurately into position meaning no damage to product or packaging. -No complex collation requirement: Less to go wrong. -Simple to operate, manage and maintain. ** Click for more **

Request for a quoteResults for

Industrial machinery - Import exportNumber of results

42 ProductsCountries

Company type

Category

- Chemical and pharmaceutical industry - machinery and equipment (13)

- Pharmaceutical industry - machinery and equipment (10)

- Food industry packaging machinery (7)

- Palletising machinery (7)

- Food industry - machinery and equipment (5)

- Beverage industry - machinery and equipment (4)

- Chemical industry - machinery and equipment (3)

- Food Industry - Machines & Equipment (2)

- Mechanical engineering - custom work (1)

- Lubrication equipment and machinery (1)

- Blades for saws and cutting machines (1)

- Brewing - machinery and equipment (1)

- Building materials, manufacture - machinery and equipment (1)

- Chemistry - laboratory products (1)

- Freeze drying - machinery and equipment (1)

- Ice-cream makers, professional (1)