- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- milling - steels and metals

Results for

Milling - steels and metals - Import export

SELMACH MACHINERY LTD

United Kingdom

The Ocean Avenger CNC Drill Line has been built for engineering metal beams and columns as well as all steel profiles including channel, angle, flat bar, base plates, square tube and round profiles. Due to its extreme versatility the Avenger has been accepted into many different industries and has made a huge impact on the small to medium fabricators around the world. Not only does this machine lay out and drills all your holes in any steel profile, the Ocean Avenger achieves this in a fraction of the time it takes you to do it manually. With options to also lay out the marks for all your welded attachments this machine virtually eliminates the need for a tape measure. The Ocean Avenger Beam Drill Line is an extremely affordable and space efficient beam processing solution as it only requires a floor space of 70ft x 9ft, making it available to smaller companies or fabricators with space limitations.

Request for a quote

SELMACH MACHINERY LTD

United Kingdom

The Volumec Drilltronic is an articulated arm drilling and tapping machine with a high performance brushless motor. Optionally, the machine can be supplied with a table or be mounted on a floor stand. In its basic form the machine is positioned manually but when fitted with the optional Volumec Assisted Positioning System (VAPS) the machine will automatically lock at the programmed position. VAPS allows easy programming from the control in X and Y coordinates for square or rectangular parts or in diameter and angle between holes for circular workpieces.

Request for a quote

SELMACH MACHINERY LTD

United Kingdom

The Meyer Precision Lathes range from 330mm to 660mm swing capacities and from 1000mm to 3000mm distance between centres. The sturdy SB industrial lathes are ideal for the tool room and for jobbing operations. The heavy duty SG machines are available in eight different sizes and have the added benefit of 2-axis DRO and the super quick tool change system fitted as standard. The ST range are large capacity industrial lathes with a 660mm swing with the distances between centres available up to 3000mm. Power traverse is fitted as standard equipment to all ST models which are operator friendly for the longer length machines. All Meyer industrial lathes are of the Gap Bed design with precision ground bed and saddle. Meyer machines are equipped with generous levels of standard equipment including 3 and 4 jaw chucks and face plate.

Request for a quote

SELMACH MACHINERY LTD

United Kingdom

BAUER BOHRMAX – the answer to economical drilling and light milling on long work pieces. The Bohrmax is a 3 axis drilling head system which can drill and mill the top surface of almost any material. The machine is of a robust design with proven German engineering components and a heavy structure to suit the engineering and fabrication industry. It is simple to use with very little CNC knowledge required. An operator can be imported via a DXF or CSV file. A qualified engineer can program parts quickly and simply making it not only ideal for large quantity production but also for one-off workpieces. An option is available to enable data to be imported via the USB port in DXF or CSV file format.

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

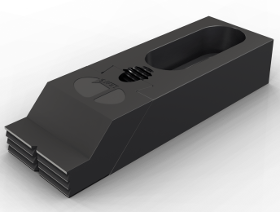

Clamps and Pulls Down Component Available Ground or Serrated Low Profile Jaw for Thinner Components Vise mounted directly to the machine bed. Low profile jaw allows for more tool clearance. The actuation not only clamps the components but also pulls it down. The jaws are available in smooth or serrated. Parts CP15 and CP16 work as stop for this vise.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

1ST MACHINE TOOL ACCESSORIES

United Kingdom

1/8" Range per Collets Sizes Up To 50.8mm Across Flats Smooth Bore as Standard, Other Finishes Available Special Profiles Available DESCRIPTION D120 Varibore hex collets are to suit 54mm capacity collet chucks. Also known as V120, these collets have a 3.175mm range. Supplied smooth as standard we can supply with alternate finishes and in special profiles. D120 suit the following collet chucks: Klamp CRL54 Klamp CRS54 Klamp QCRL54 Crawford CDC54 Crawford CDC-54-S Crawford QC-54

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

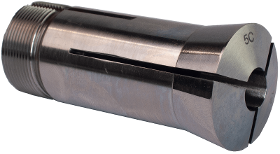

0.5mm and Imperial Increments also Available Accurate and Durable Suitable for 1st and 2nd Operation Work Handening ensures Longevity of Collets Available in a wide range of sizes 5C collets offer the user flexibility to do both first and second operation work using the same collet style. These collets are hardened and tempured to ensure flexibility and durability. The sizes below are in 0.5mm increments but we are able to supply both imperial increments and even special sizes.

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

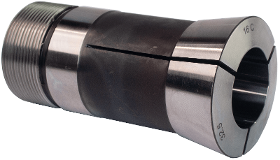

0.5mm and Imperial Increments also Available Accurate and Durable Suitable for 1st and 2nd Operation Work Handening ensures Longevity of Collets Available in a wide range of sizes 16C collets offer the user flexibility to do both first and second operation work using the same collet style. These collets are hardened and tempered to ensure flexibility and durability. The sizes below are in 1mm increments but we are able to supply both imperial and 0.5mm increments and even special sizes.

Request for a quote

UKF STAINLESS LTD (THE UKF GROUP)

United Kingdom

Traditionally, perforated tube is manufactured through a lengthy operation starting with flat strip metal that goes through four stages of processing before completion. This is a time-consuming and costly procedure with chances for complications throughout the process. We’ve innovated the way perforated tube is processed by perforating pre-formed tube in one operation. This saves you time, money and hassle as it eliminates the long process and any production issues that can occur, while providing a visually enhanced product. Our five perforating machines can perforate stainless steel, titanium and aluminium tubes from 38mm to 101.60mm⌀, in lengths up to 750mm long. The specialist tool design allows tube perforation in various patterns that can be tailored to produce bespoke and unique patterns and shapes.

Request for a quote

UKF STAINLESS LTD (THE UKF GROUP)

United Kingdom

We provide our customers with the opportunity to get their materials processed before they even leave the warehouse – providing a leaner and more cost-effective manufacturing process. With large quantities of material stored on site, you’ll benefit from shorter lead times and better material availability compared to third party subcontractors. Thanks to recent investments, our manipulation service operates across two sites, equipped with several single and multi-stack benders and end-forming machines. Through these sites, we provide CNC and Press tube bending, end-forming and cruxiforming - providing the Group the capability to process and deliver orders faster than ever before. Our manipulation services are currently being employed within the automotive, domestic appliance and filtration industries.

Request for a quoteResults for

Milling - steels and metals - Import exportNumber of results

11 ProductsCompany type