- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- electric equipment

Results for

Electric equipment - Import export

DOREY

France

The automatic welding machine P2 is the innovative successor of the successful P models and an efficient and manoeuvrable device for welding truck tarpaulins, tents, awning materials and advertising banners. It produces optionally 20, 30, 40 and 45 mm wide overlap welds and may also be converted for welding in welting ropes. In addition, by mounting hem welding accessories, the automatic machine can without any difficulty be used for the production of 20 mm, 30 mm, 40 mm and 45 mm hems. The heat output of up to 4000 W 230 V AC is infinitely variable from 20 to 700 °C for an individual adjustment to different materials. The P2 starts automatically after the weld head has been swivelled in. In addition, the infinitely variable speed adjustment of the modern generation of motors with their performance of up to 18 m/min., in conjunction with the holding down device for crease free welding, makes for an optimum welding result.

Request for a quote

COPIER MACHINERY

Netherlands

The core of the Rotoweld technology is its unique vision-based penetration control system. It enables any operator to perform high-quality girth welds after just a few hours of training. Like the welder’s eyes and hands, the system continuously analyzes the image of the root weld pool picked up by a video camera integrated into the welding arm. Unique algorithms use this information to adjust welding parameters, such as travel speed, wire feed rate, arc voltage, or weaving width. This constantly adapts the process to varying conditions, such as changes in the gap, alignment, root face, or temperature. The computer’s fast reaction time means the machine can work at high deposition rates and travel speeds at which weld pool conditions are too critical to be sustained by hand.

Request for a quote

COPIER MACHINERY

Netherlands

The core of the Rotoweld technology is its unique vision-based penetration control system. It enables any operator to perform high-quality girth welds after just a few hours of training. Like the welder’s eyes and hands, the system continuously analyzes the image of the root weld pool picked up by a video camera integrated into the welding arm. Unique algorithms use this information to adjust welding parameters, such as travel speed, wire feed rate, arc voltage, or weaving width. This constantly adapts the process to varying conditions, such as changes in the gap, alignment, root face, or temperature. The computer’s fast reaction time means the machine can work at high deposition rates and travel speeds at which weld pool conditions are too critical to be sustained by hand.

Request for a quote

NINGBO FRIMA INDUSTRY CO. LTD.

China

Product Introduction: load cells are available in the capacities from 5kg to 500kg. Alloy steel & stainless steel construction construction with single shear beam type. Sealed welding ,waterproof, anti-corrosion and suitable for all kinds of environment. Integral structure and easy installation. Suitable for electronic platform scale, hopper scales and other electronic weighing devices. Features: Capacity :5kg to 500kg Defend grade: IP67 & IP68 High accuracy. Alloy steel & stainless steel single shear beam Low profile and nice exterior

Request for a quote

PJM MECHANICAL CO.,LTD

China

Low Backlash: Backlash is under 3 arcmin.Backlash for 2 stage speed reduction is within 5 arcmin High Efficiency:Efficiency for 1 stage model exceeds 95%,2 stage model exceeds 92% Size:PLF060/PLF080/PLF090/PLF120/PLF160 Output Rated Torque Range:From 9Nm to 500Nm Adapter-bushing connection,can be attached to any motor No Grease Leakage and Maintenance-free Planetary Gearbox Application:Aerospace,military industry,Medical health,electronic information industry,Industrial robots,production automation,CNC machine tool manufacturing industry,Auto industry,textile,printing,food,metallurgical,environmental protection engineering,warehouse logistics industry

Request for a quote

SRI - SAINT-REMY INDUSTRIE

France

We produce transformer connections & connections for providing power on welding guns in pure copper, aluminium bronze, tin and lead bronze as well as brass. Pieces are delivered as-cast, rough or fully machined.

Request for a quote

SINOP SMP

Czech Rep.

Standing transformer welding sources with swinging arm Digital Control Unit Maximal sheet thickness 5 + 5 mm Steel, Stainless steel Aluminum alloys

Request for a quote

SINOP SMP

Czech Rep.

Semiautomatic capacitor-discharge stud welding with ignition tip M3 – M8 Diameter 3 – 8 mm Steel, Stainless steel Aluminium alloys Welding sources LBS

Request for a quote

SINOP SMP

Czech Rep.

MIG/MAG welding, reference number of 131/135 TIG(WIG) welding, reference number of 141 and 142 MIG soldering with an additional material CuSi Materials: Steel, Stainless steel and Aluminum Professional power sources by company Fronius Welding tables by company Siegmund

Request for a quote

SINOP SMP

Czech Rep.

For high volume production, but also for smaller batches MIG/MAG welding TIG (WIG) welding with wire feeding MIG soldering with an additional material CuSi Fixture design and development in house

Request for a quote

SINOP SMP

Czech Rep.

Since 2011 we are proud to have robotic laser welding technology (currently 3 welding cells) at our disposal. The laser beam is generated with the solid-state laser source TruDisk with a maximal power output of 4 kW. Laser welding stands for the unrivalled welding productivity and a low heat application. This guarantees a minimal distortion and an outstanding appearance of the weld seam. The clamping fixtures for robotic welding are developed and produces in house. Very small heat affected zone resulting in the low distortion of the components Smooth and symmetrical weld seam High process stability and high welding speed Outstanding weld seam quality with a minimal or no necessity for an additional surface treatment Fixture design and development in house

Request for a quote

UNITED PROARC CORPORATION

Taiwan R.O.C.

1. High frequency protected. 2. Tilting angle range from 0° ~ 90° 3. Main shaft equip a Ø14 mm through hole for pipe welding or shield gas. 4. Faceplate contains 3 straight slots for 3-jaw chuck (PG-050L or PG-095L in option). *CE Conformity

Request for a quote

MAHERAS LTD.

Bulgaria

We have 10 TIG, MIG and ARC welding machines. Our welders are among the best in Bulgaria. We can weld everyone steel.

Request for a quote

UNITED PROARC CORPORATION

Taiwan R.O.C.

Available for stroke 50mm/ 75mm/ 100mm /150mm / 200mm

Request for a quote

UNITED PROARC CORPORATION

Taiwan R.O.C.

Available for diameter 150mm/450mm/500mm of workpiece.

Request for a quote

UNITED PROARC CORPORATION

Taiwan R.O.C.

TR-KB Series 1. Capacities range from 15,000 to 60,000 kilograms. 2. Superior worm gears reducer designed to provide high torque and low backlash. 3. Synchronized AC inverter drive control for two motors. 4. Metallic rollers bounded with natural rubber. 5. TR-KB series designed with symmetrical roller for quick and accurate centering adjustment. 6. Adjustment bolt for different work diameter. 7. Standard hand pendant with Forward-Stop-Reverse, speed potentiometer. 8. High frequency protected control box. 9. Fast/Slow footswitch - optional.

Request for a quote

UNITED PROARC CORPORATION

Taiwan R.O.C.

1. Capacities range from 1,000 to 6,000 kilograms. 2. For pipes or vessels rotation. 3. Metallic rollers bounded with polyurethane. 4. Quick, accurate roll centering adjustment. 5. High frequency protected. *CE Conformity

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

UNITED PROARC CORPORATION

Taiwan R.O.C.

1. For pipes or vessels rotation. 2. Metallic rollers bounded with polyurethane. 3. Quick, accurate roll centering adjustment. 4. Standard hand pendant with Forward-Stop-Reverse, speed potentiometer. 5. High frequency protected. *CE Conformity

Request for a quote

UNITED PROARC CORPORATION

Taiwan R.O.C.

1. Support tungsten / electrode size: Ø1.0 ~ 4.8 mm 2. Grinding angles from 10° ~ 60° 3. Tungsten grinder is easy set up 4. No equipment changes required 5. Electrode notching station for simple cut off available 6. Safety 7. Good welding quality 8. Increase welding productivity *CE Conformity

Request for a quote

UNITED PROARC CORPORATION

Taiwan R.O.C.

1. All welded steel frame structure. 2. For long weldments rotation. 3. Capacities range from 500 to 20,000 kilograms. 4. Machined "T" slots table with pilot and through hole. 5. A. C. inverter drive for rotation. 6. Forward-Stop-Reverse and variable speed control are standard. 7. Totally gear-safe design. 8. Maintenance-free grounding system. 9. Optional adjustable table height to fit larger workpiece. *CE Conformity

Request for a quote

UNITED PROARC CORPORATION

Taiwan R.O.C.

1. Adjustable roller center line setting automatically when loading workpiece. 2. Suitable for diameter from Ø300mm ~ Ø6,000mm. 3. Weight capacity from 12 tons ~ 60 tons.

Request for a quote

UNITED PROARC CORPORATION

Taiwan R.O.C.

TR-0103 Turning roll with standard control box. TR-0104 Turning roll with digital control box. 1. Turning roller, the best solution for big tank welding. 2. For pipes or vessels rotation. 3. Metallic rollers bounded with polyurethane. 4. High frequency protected. *CE Conformity

Request for a quote

UNITED PROARC CORPORATION

Taiwan R.O.C.

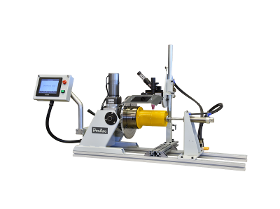

1. Provides circumferential welding (lathe welding) for tube, pipe, vessel…etc. in an easy operation but good welding quality solution. 2. This optimizes any process which reduces welding costs and improves the quality of the weld. 3. Suitable for TIG (GTAW), MIG (GMAW), Plasma (PAW) and Sub Arc welding (SAW) process. The style main frame design that allows 7 angular position adjustment from vertical to horizontal position (0° ~ 90°). Index welding is also available in this series.

Request for a quote

UNITED PROARC CORPORATION

Taiwan R.O.C.

1. Provides good circumferential welding (lathe welding) for tube, pipe, vessel…etc. in an easy operation way. 2. This optimizes any process which reduces welding costs and improves the quality of the weld. 3. Suitable for TIG (GTAW), MIG (GMAW), Plasma (PAW) and Sub Arc welding (SAW) process.

Request for a quote

UNITED PROARC CORPORATION

Taiwan R.O.C.

ProArc PCW Precision Circumferential Welder provide all of the features necessary to position and rotate parts for circumferential welding. Advantage: 1. The extreme accuracy welding lathe with servo motor control for turntable and transverse carriage. 2. Allow unskilled people to get high welding quality and consistently production progress. 3. Designed to enable horizontal or vertical configuration for more flexible welding solution. 4. ProArc offers a user-friendly and intuitive controller interface that allows users to implement the system quickly. 5. ProArc designed AVC (option) Enable to set the parameter of AVC in the integrated controller. 6. Motorize carriage on X axis (option) Ball screw drive system with dual linear guide way. * Positioning accuracy is +- 0.01mm * Travel speed 1 ~ 10,000 mm/min 5. Maximum through hole for diameter 80mm. *CE Conformity

Request for a quote

UNITED PROARC CORPORATION

Taiwan R.O.C.

PT-103 welding positioner with standard control box PT-104 welding positioner with digital control box Rotation speed A type: 0.3-4 rpm B type: 0.6-8 rpm C type: 0.8-12 rpm D type: 1-16 rpm 1. High frequency protected. 2. Machined "T" slots table with pilot and through hole. 3. High quality worm gear reducers for smooth operation and minimal backlash. 4. Free maintenance grounding system. *CE Conformity

Request for a quote

UNITED PROARC CORPORATION

Taiwan R.O.C.

4 Major Advantage: 1. Cost effective and modular design.to increase welding productivity. 2. Set up with CB-107-1 Sequence controller : * User-friendly sequence controller. * Save 100 sets of programs * Even a non-experienced user can learn how to operate in few minutes. 3. High frequency protected 4. Suitable for different welding processes like TIG, MIG and plasma welding. 5. 2 year warranty *CE Conformity

Request for a quote

UNITED PROARC CORPORATION

Taiwan R.O.C.

1. ProArc delivers compact design welding manipulator in a economic solution. 2. It can work with welding positioner or turning rolls as a cost saving welding package to make your welding stable and easy. 3. Transverse adjustment by manually through quick lock handle. 4. Boom lifting can be adjust by manually or electrical control (option). 5. Standard with 360 deg. rotation base and quick torch position adjustment manual slide. 6. Quick torch position adjustment in X/Y/Z axis through manual slide. 7. Compact design to save floor space and easy for installation.

Request for a quote

UNITED PROARC CORPORATION

Taiwan R.O.C.

1. ProArc manipulators are heavy duty and precise automatic welding systems. It can support both circumferential and longitudinal welding application from small tube to big tank. 2. The stroke of column and boom is available from 2m x 2m to 7m x 7m. 3. ProArc manipulators are heavy duty, precise automatic welding systems. They are designed for circumferential or longitudinal welds of great length. 4. All manipulators are available as bolt-down or free standing base, and heavy duty table bearing mount for column rotation or be mounted on to travel car. 5. All ProArc manipulators have anti-fallen device. 6. Controls include up/down, right/left travel switch speed potentiometer and high rapid travel.

Request for a quoteResults for

Electric equipment - Import exportNumber of results

65 ProductsCountries