- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- steels and metals - machining

Results for

Steels and metals - machining - Import export

SOOCHOW ADVANCE INDUSTRIES CO., LTD.

China

Precision Machine Parts manufactured by CNC machining centre Soochow Advance Industries Co., Ltd., (website: www.sai-parts.com) supplies custom OEM mechanical parts, industrial fasteners, screws, bolts, nuts, industrial fittings, electronic hardware by precision CNC machining, CNC turning, CNC milling, CNC engineering.

Request for a quote

SOOCHOW ADVANCE INDUSTRIES CO., LTD.

China

nozzle part manufactured by CNC turning and milling on sliding head multi-axis CNC lathe material: brass size: diameter 19.5 mm, length 16 mm tolerance: DIN 2768-F With sliding head multi-axis CNC lathes, we are capable of producing complex parts requiring turning, milling, drilling, tapping, broaching etc in one setup.

Request for a quote

SOOCHOW ADVANCE INDUSTRIES CO., LTD.

China

Steel Machining Parts manufactured by CNC turning & milling Soochow Advance Industries Co., Ltd., (website: www.sai-parts.com) supplies custom OEM mechanical parts, industrial fasteners, screws, bolts, nuts, industrial fittings, electronic hardware by precision CNC machining, CNC turning, CNC milling, CNC engineering.

Request for a quote

SOOCHOW ADVANCE INDUSTRIES CO., LTD.

China

Aluminum Alloy Parts by Precision CNC Machining Soochow Advance Industries Co., Ltd., (website: www.sai-parts.com) supplies custom OEM mechanical parts, industrial fasteners, screws, bolts, nuts, industrial fittings, electronic hardware by precision CNC machining, CNC turning, CNC milling, CNC engineering.

Request for a quote

SOOCHOW ADVANCE INDUSTRIES CO., LTD.

China

Aluminium Alloy Machined Parts manufactured by slideing head multi axis CNC lathe Soochow Advance Industries Co., Ltd., (website: www.sai-parts.com) supplies custom OEM mechanical parts, industrial fasteners, screws, bolts, nuts, industrial fittings, electronic hardware by precision CNC machining, CNC turning, CNC milling, CNC engineering.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

SYSKOMP GMBH - EMICO

Germany

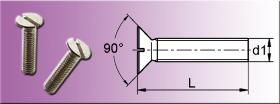

Countersunk screws - metal ~DIN 963 (~DIN EN ISO 2009) Material: machining steel 4.8 zinc-plated

Request for a quote

SYSKOMP GMBH - EMICO

Germany

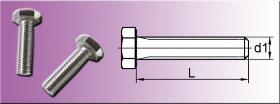

Hexagon head screws - metal ~DIN 933 (~DIN EN ISO 4017, threaded to head) Material: machining steel 4.8 zinc-plated

Request for a quote

SYSKOMP GMBH - EMICO

Germany

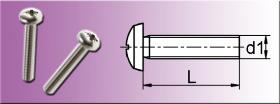

Lens head screws - metal, cross slot ~DIN 7985 (~DIN EN ISO 7045 - form H) Material: machining steel 4.8 zinc-plated

Request for a quote

OTTO EICHHOFF GMBH & CO. KG

Germany

Turned parts Long turned partes, small turned parts Turned, milled and grinded parts Thread inserts in brass, steel and stainless steel Possible materials: Alloy AlCuMgPb, AlZn5,5MgCu etc. Brass CuZn39Pb3, CuZn40Pb2 etc. Stainless steel 1.4301, 1.4305, 1.4571, 1.4401, 1.4101 etc. Steel Machining steel, St52, St37, C45, etc. Special steels Titan, Hastelloy, Copper, Bronze etc. Surface treatments may be done as follows: Galvanizing, nickel, brown, hot-dip galvanizing, phosphating, anodizing, chrome plating, painting, powder coating, plasma coating, sandblasting, Tuflok coatings. All common surfaces as VDA standard are possible (zinc-nickel, zinc flake). Heat treatments such as Plasma / gas nitriding, carbonitriding, hardening, carburizing, vacuum hardening, tempering etc.

Request for a quote

UKF STAINLESS LTD (THE UKF GROUP)

United Kingdom

Traditionally, perforated tube is manufactured through a lengthy operation starting with flat strip metal that goes through four stages of processing before completion. This is a time-consuming and costly procedure with chances for complications throughout the process. We’ve innovated the way perforated tube is processed by perforating pre-formed tube in one operation. This saves you time, money and hassle as it eliminates the long process and any production issues that can occur, while providing a visually enhanced product. Our five perforating machines can perforate stainless steel, titanium and aluminium tubes from 38mm to 101.60mm⌀, in lengths up to 750mm long. The specialist tool design allows tube perforation in various patterns that can be tailored to produce bespoke and unique patterns and shapes.

Request for a quote

UKF STAINLESS LTD (THE UKF GROUP)

United Kingdom

We provide our customers with the opportunity to get their materials processed before they even leave the warehouse – providing a leaner and more cost-effective manufacturing process. With large quantities of material stored on site, you’ll benefit from shorter lead times and better material availability compared to third party subcontractors. Thanks to recent investments, our manipulation service operates across two sites, equipped with several single and multi-stack benders and end-forming machines. Through these sites, we provide CNC and Press tube bending, end-forming and cruxiforming - providing the Group the capability to process and deliver orders faster than ever before. Our manipulation services are currently being employed within the automotive, domestic appliance and filtration industries.

Request for a quoteResults for

Steels and metals - machining - Import exportNumber of results

12 ProductsCountries

Company type