- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- agriculture - machines & equipment

Results for

Agriculture - machines & equipment - Import export

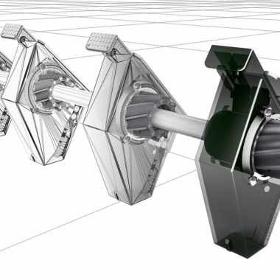

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

These are the parts used in precision machinery,after processing, local sandblasting is carried out.

Request for a quote

INTERNORM KUNSTSTOFFTECHNIK GMBH

Germany

Seeder housing as a completely assembled assembly group - this is used in mechanical seeders for metering the seed or fertilizer.

Request for a quote

ATMOSFER MACHINERY

Turkey

We are proud to present our state-of-the-art multifunctional production plant, a groundbreaking innovation designed to streamline and simplify the process of manufacturing various solutions, including liquid fertilizers such as NPK, UAN, and more, as well as AUS solutions like AdBlue. This fully automatic and smart production plant is set to revolutionize the industry of liquid fertilizer.

Request for a quote

XIAN HUAN-TAI TECHNOLOGY & DEVELOPMENT CO., LTD.

China

Our company has 25 years experience for manufacture different kinds of gears.And our company has many advanced production equipments. such as CNC forming grinding wheel grinding machines, gantry machining centers, four axis and five axis machining centers, CNC lathes, CNC gear shapers, CNC milling machines, CNC hobbing machines, gear chamfering machines.and more than 40 sets of processing and testing equipment. we can provide various professional production services such as precision gear wheel machining, CNC machining, CNC turning machining, and so on.

Request for a quote

PLANT OF AGRICULTURAL MACHINERY

Ukraine

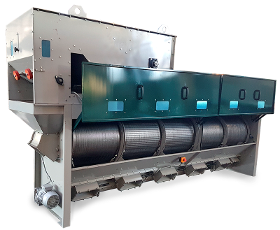

The OBC-355 universal grain cleaning separator is the most multifunctional drum-type machine for cleaning grain in the world. The number of operating options for the OBC-355 grain cleaning separator exceeds 50. The multifunctionality of the OBC-355 drum cleaner allows it to be used to separate and calibrate a wide range of products (for example: a mixture of any grain, grain with very high clogging, corn with very high humidity, cotton fibers and seeds, glass balls, etc.). The OBC-355 grain cleaning machine can be used both for high-quality calibration and for preliminary cleaning with large volumes of processing. Multifunctionality is achieved due to the innovative design of OBC-355, consisting of a large number of flap valves, screws and 2 main parts: an aspiration unit that removes light impurities depending on the air flow controlled by the regulation of aspiration; cleaning and calibration unit with a rotating drum that removes small and large impurities

Request for a quote

PLANT OF AGRICULTURAL MACHINERY

Ukraine

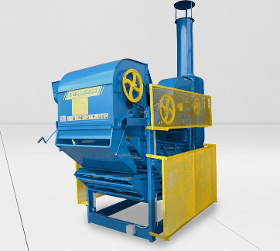

OBC-25CE is a stationary grain cleaning machine equipped with unloading elevator additionally. Presence of such kind of elevator simplifies grain cleaning process and makes it possible transferring grain into vehicles, grain vessels, trailers, big bag etc. Machine can also be equipped with a boot elevator and cyclone if necessary. On customer request wheels can be installed to OBC-25CE that turns the unit into mobile one. OBC-25CE performs grain and seeds cleaning using an aspiration system and sieves. Spreader separates impure grain in two equal parts and directs it to air channels. Fan airflow takes light impurities out. Larger impurities are captured with settling chamber from air stream. After that grain purified in aspiration system comes to upper and lower sieves. At these sieves grain gets cleared of impurities kind of different size. Pure grain is collected at the bottom of OBC-25CE and unloaded with built-in elevator.

Request for a quote

PLANT OF AGRICULTURAL MACHINERY

Ukraine

Stationary grain cleaner OBC-25S performs cleaning of cereals, legumes, sunflower, sorghum, rapeseed, corn, etc. Grain cleaner OBC-25S is installed in existing grain cleaning units or mounted separately. OBC-25S is equipped with a receiving chamber, an air-cleaning part, sieves, a feed waste screw. All working bodies are mounted on the frame. OBC-25S performs cleaning of grain and seeds using an aspiration system and sieves. The distributor divides the grain with impurities into two equal parts and directs it to the air channels. Airflow through the fan carries off light impurities. Larger impurities from the air stream are captured by the settling chamber. Further, the grain purified by the aspiration system falls on the upper and lower sieves. On sieves, the process of cleaning grain from impurities that differ from grain in size occurs. The sieves are cleaned with brushes. If necessary, OBC-25S can be additionally equipped with loading and unloading elevators, as well as a cyclone.

Request for a quote

PLANT OF AGRICULTURAL MACHINERY

Ukraine

The OBC-25SC grain cleaner cleans any grain using 8 sieves and an aspiration system with a built-in cyclone. The installation of a cyclone at OBC-25SC made it possible to solve the problem of cleaning the air emitted by the OBC-25SC fan from dust and light impurities (small parts of leaves, grains, insects, sand, etc.). Previously, this was solved by installing a separate cyclone near the OBC-25S, conducting an air duct from the OBC-25S fan to it, and installing a clean air exhaust system from the cyclone. This led to significant additional costs and required a large free space. Now OBC-25SC with an integrated cyclone that successfully copes with cleaning a heap of grain, saves space and money. Additional advantages of the grain cleaning machine OBC-25SC: - high productivity with small sizes; - simple, durable design; - quick sieve change; - automatic cleaning of sieves with built-in brushes; - can be equipped with lifts, cyclone pipe and wheels.

Request for a quote

PLANT OF AGRICULTURAL MACHINERY

Ukraine

The MPO-50M machine carries out quick preliminary cleaning of grain , legumes, oilseeds and industrial crops, corn, sorghum, rapeseed, sunflower seeds and grass. Designed for operation as a part of stationary production lines of grain cleaning complexes. Preliminary cleaning of grain in MPO-50M is carried out according to two main parameters - size and aerodynamic properties . The advantages of MPO-50M are that it is a universal high-performance machine for quick pre-cleaning of any grain or seeds with a moisture content of up to 70%. MPO-50M can easily cope even with the cleaning of grain heavily clogged with straw and other impurities. High speed of operation increases production volumes per unit time and allows you to quickly move from the stage of preliminary preparation of raw materials to the next stage in order to better preserve seeds and grain, prepare them for drying and active ventilation, increase the efficiency of subsequent cleaning.

Request for a quote

PLANT OF AGRICULTURAL MACHINERY

Ukraine

The AS-60 air separator is used when cleaning grain to separate dust and light fractions from the grain. It can be used for different types of cereals, for example, for wheat, durum wheat, corn, rye, soy, oats, buckwheat, millet, rape, rice, as well as for sunflower, peas, chickpeas, beans, cocoa beans, etc. Cleaning grain from dust and light impurities ensures its long-term storage and helps to prevent various potential threats. Due to the unique design of the cascade type, the AS-60 air separator provides high quality cleaning of grain from dust and light impurities. Air speed and grain feed are very easy to adjust with 3 handles. This allows you to adjust the separation settings at any time depending on the properties of the grain being cleaned. Due to its simple, effective design and wide adjustment range, the AS-60 air separator has many applications. This separator can be used separately, installed in stationary grain cleaning lines or used as part of mobile grain cleaner.

Request for a quote

PLANT OF AGRICULTURAL MACHINERY

Ukraine

The universal seed separator with cyclone OBC-355C is the most multifunctional drum separator for cleaning any grain and seeds. The number of applications for this separator exceeds 50. This is achieved through an innovative block design with a large number of reversible valves and an additional auger at the bottom of the cleaning unit. The main parts of the OBC-355C are the OBC-355 seed separator and the aspiration system, to the outlet of which a cyclone with 3 supports is connected through an air duct. Grain separators OBC-355C have the following main advantages: Maximum versatility in application. Greater cleaning efficiency. High accuracy of grain calibration by aerodynamic properties, width and thickness. Minimal vibration during operation. Fast replacement of sieves. Gentle handling of seeds and grain. Adjustable performance. The presence of a cyclone that traps dust and light impurities. For more information about the advantages of OBC-355C, see the plant’s website.

Request for a quote

PLANT OF AGRICULTURAL MACHINERY

Ukraine

OBC-25C self-propelled grain cleaning machine with a cyclone is the latest innovative development. Main advantages of using the OBC-25C: 1. Versatility - used for cleaning any kind of grain and seeds. 2. High quality cleaning and minimal damage to the grain. 3. Move independently and load themselves with grain without help of other machines or people. 4. Can independently load transport up to 3 meters high. 5. Easy and convenient operation and maintenance. 6. Capacity up to 25 tons of grains per hour. OBC-25C with a cyclone is the best self-propelled technique for high-quality and high-performance cleaning of grain, heap, cereals, legumes, oilseeds, corn, sorghum, sunflower, rape from impurities in open areas and in warehouses. You can also choose the model of the OBC-25C grain cleaning machine with an extended elevator, frequency converter, remote control, lighting, bumper, hopper, screw loader. OBC-25C is an ideal machine for cleaning grain.

Request for a quote

PLANT OF AGRICULTURAL MACHINERY

Ukraine

In the self-propelled grain cleaner ОВС-25D, cleaning is carried out not on 8, but on 9 sieves. The presence of an additional sieve allows better separation of pure grain and impurities. An additional sieve is installed in the housing of the auger of feed waste and divides them into two parts by size. Due to this, the ОВС-25D grain cleaning machine divides the grain into 4 fractions, and not 3 as ОВС-25 with 8 sieves. ОВС-25D has a capacity of up to 25 tons per hour. ОВС-25D, like other models of ОВС-25 grain cleaning machines we produce, is a self-propelled machine. ОВС-25D independently rides and loads itself with grain without the help of other mechanisms or personnel. Loading is carried out by a chain elevator, which is located in front of the ОВС-25D and picks up grain at a width of 5.3 meters. Grain cleaning in ОВС-25D is carried out both by regulated air flow and sieves, which allows to obtain high quality cleaning.

Request for a quote

PLANT OF AGRICULTURAL MACHINERY

Ukraine

Instead of a dust separator and a pneumatic conveyor, a cyclone is installed on a self-moving OBC-25CB grain cleaner, and a hopper instead of scraper feeders. The volume of the hopper of the OBC-25CB grain cleaning machine is about 1 cubic meter. OBC-25CB grain cleaner cyclone collectsdust, straw and light impurities. As a result, personnel can work without respirators and dust does not settle on already cleaned grain, people and equipment. The hopper of the OBC-25CB grain cleaning machine allows the grain truck to unload grain directly into the hopper, and not onto the floor. As a result, grain trauma, energy consumption and wear of the OBC-25CB loading conveyor are reduced. You can also load grain into the OBC-25CB hopper with a screw, noriya, loader, etc. Grain cleaning in OBC-25CB is carried out by adjustable air flow and sieves, which allows to obtain high quality cleaning. You can also purchase an OBC-25CB grain cleaner with a hopper and scraper feeders.

Request for a quote

PLANT OF AGRICULTURAL MACHINERY

Ukraine

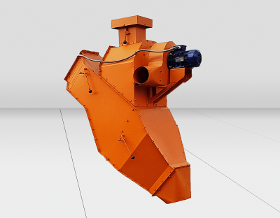

The powerful PZM-170 grain thrower has productivity up to 170 tons per hour. With its help it is possible to carry out quick loading of grain into grain carriers, cars, railway cars, containers, barges, trailers, etc. The grain thrower PZM-170 also quickly loads and unloads both low and high grain stores. Another important function that the PZM-170 can perform is the transfer of grain in closed warehouses and in open areas. This is necessary for long-term storage of grain. In the process of grain transfer, its moisture content and contamination by light impurities are reduced. Main advantages of using grain throwers: - versatility - used for loading any transport, storage of any grain in piles up to 9 m high; - energy efficiency and gentle handling of grain; - ability to move by itself and load itself with grain without help of other machines or people; - easy and convenient for people operation and maintenance; - reliable construction with the use of available components.

Request for a quote

PLANT OF AGRICULTURAL MACHINERY

Ukraine

Self-propelled grain loader with a large hopper PZM-170B is intended for unloading grain from grain carriers and trailers directly into the hopper of this grain thrower and subsequent loading of granaries to a height of up to 9 meters. Grain loader PZM-170B is also successfully used for loading grain carriers, trailers, wagons, ships, containers and trucks. The size of the hopper is 3.12 meters wide, 1 meter high with a lowered front wall, and a volume of about 4 cubic meters. It is convenient when handling grain in ports, grain warehouses and other premises, or in open areas. Self-propelled grain loader with a large hopper PZM-170B is used in the following sequence: grain loader PZM-170B drives up to the loading point on its own; the hopper is lowered into the working position and rests on the surface of the warehouse; a car, a loader or a tractor with grain drives up to the hopper; the loader throws grain through a special guide pipe to a height of up to 9 m and up to 25 m in lengt

Request for a quote

PLANT OF AGRICULTURAL MACHINERY

Ukraine

The PZM-60 self-propelled grain loader combines the advantages of a PZM-120M grain thrower and an auger grain loader. The grain loading speed and loader capacity are quickly regulated and range from 10 to 70 tons per hour. Unlike a conventional auger, PZM-60 moves independently and loads itself with grain with the existing scraper feeders. The pick-up width is adjustable and reaches 6 meters. During operation of the PZM-60 grain loader, there is practically no dust. The grain loading height is adjustable and ranges from 2.7 m to 4.27 m. The auger is installed on a special platform that rotates 280 degrees around its axis. This allows you to change the direction of grain loading in 2 seconds. The screw rotation speed is easily adjusted by the installed frequency converter. It is also possible to install a hopper on the PZM-60 screw loader. There is also the possibility of using PZM-60 for moistening grain by installing additional nozzles and a hydraulic pump.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

PLANT OF AGRICULTURAL MACHINERY

Ukraine

The PZM-170P mobile handler with a conveyor is designed to receive any grain, seeds, granules, pellets in a granary, grain cleaning complex, as well as quick transshipment of bulk cargo from trucks, trailers and other vehicles to any loaders, ships in the port, on the railway or in any other place. This portable handler can also be used to transfer grain from grain trucks to other transport equipment, elevators, augers, belt conveyors, big bags, etc. We produce a whole range of mobile grain loaders designed for use in farms, grain receiving points, elevators, ports on the railway and just in the field. They differ in volume, overall dimensions and adaptation to different models of conveyors. Portable grain loaders of our production have a simple reliable design. The productivity of a mobile grain handler depends on the type of grain or other bulk cargo and reaches 200 tons per hour. Electricity consumption for reloading 1 ton of grain is only 0.04 kW.

Request for a quote

PLANT OF AGRICULTURAL MACHINERY

Ukraine

The grain thrower PZM-120M is an ideal machine for fast loading of any grain into any transport. PZM-120M grain thrower is also used to transfer grain from one place to another. During the transfer process, moisture and light impurities are partially removed from the grain. Transfer of grain is necessary during its long-term storage. PZM-120M grain loader quickly loads grain into grain carriers, automobiles, railway cars, containers, barges, trailers, etc. A full load of a grain truck takes about 15 minutes. The grain thrower PZM-120M is used to work with grain, oilseeds, legumes and industrial crops, while the trauma to the grain is minimal (less than 0.1%). During the operation of the grain thrower, the grain is fed to the conveyor using scraper feeders. The conveyor loads the grain into the trimmer, which throws it through a special guide tube. The trimmer with the pipe easily rotates 257 degrees. Changing the direction and height of grain flight is carried out in less than 3 sec.

Request for a quote

PLANT OF AGRICULTURAL MACHINERY

Ukraine

The mobile grain cleaner OBC-355CMA with a cyclone and a loading auger is designed for cleaning and calibrating any grain and preparing high-quality seed material. It is an innovative combination of 5 sieves installed in a drum with adjustable rotation speed and angle of inclination, an adjustable powerful aspiration system, a large number of overhead valves and augers. The mobile grain cleaner OBC-355CMA has enormous possibilities and more than 50 applications ranging from preliminary cleaning of grain to high-precision calibration of grain at once from 3 different types of plants for seeds. Mobile grain cleaning machine OBC-355CMA is easily transported by minibus, small truck or tractor on the road. This is the best solution for farms with several grain warehouses, as well as for businessmen providing grain cleaning services. Take full advantage of this mobile grain cleaner and take your business to the next level.

Request for a quote

PLANT OF AGRICULTURAL MACHINERY

Ukraine

ОВС-70L is a self-propelled high-performance hybrid of a grain cleaning machine and a grain loader. The main difference between ОВС-70L and ОВС-70M4 is that the ОВС-70L has an elongated unloading elevator, but there is no trimmer and sieves. Cleaning grain of any humidity or contamination is carried out using an aspiration system and a mesh conveyor. For better grain cleaning, a self-propelled grain cleaner OBC-70M4L is used. At ОВС-70L, the cleaned grain is not conveyed by the conveyor to the trimmer, but directly to the trailer, big-bag, hopper, or poured down. Functions performed by the self-propelled grain cleaner ОВС-70L: - cleaning grain heaps of legumes, grains, cereals, corn, sunflower, rapeseed, sorghum, etc .; - loading grain directly into vehicles with a side height of up to 3 m; - loading grain into big bags, bags, bins, loader buckets, etc.; - mechanical shoveling of grain, accompanied by its simultaneous cleaning, as well as partial drying in open areas or granaries.

Request for a quote

PLANT OF AGRICULTURAL MACHINERY

Ukraine

OBC-70M4L is a self-propelled high-performance combination of a grain cleaning machine, a grain thrower and a grain loader, which minimizes human labor when cleaning, shipping and moving grain. OBC-70M4L has the following main advantages: 1. Versatility - the machine cleans,loads, moves and dries all kinds of grain. 2. Used for loading any kind of transport, handling and stacking any kind of grain into piles up to 9 m high. 3. Capacity up to 80 tons of grains per hour. 4. OBC-70M4L is a mobile machine and can be easily transported to another grain warehouse or to another farm. 5. Consume 0.25 kWh of electricity for cleaning, drying, loading and storage of ton of grain. 6. Move independently and load itself with grain without help of other machines or people. 7. Change the direction and height of the grain flight in less than 3 seconds. 8. Easy, safe and convenient operation and maintenance. 9. Minimal grain damage. 10. Good price and quick payback.

Request for a quote

PLANT OF AGRICULTURAL MACHINERY

Ukraine

Self-propelled grain cleaning complex OBC-70M4 is an ideal solution for cleaning, drying and loading grain any kind of transport. High cleaning quality is ensured by the use of a built-in mesh conveyor, sieves and a powerful adjustable air aspiration system. OBC-70M4 moves independently and cleans and loads grain without the help of other machines and people. This grain cleaner has a capacity of 80 tons per hour for all major crops. At the same time, energy consumption is only 0.25 kW / h for processing 1 ton of grain. The height of storage and loading of grain is up to 10 meters, the flight range of grain is up to 25 meters. Self-propelled grain cleaning complex OBC-70M4 has triple control - automatic, manual and remote. The design of this grain and seed cleaning equipment is as safe and convenient as possible. Anyone can work on OBC-70M4 after instruction, because it is very easy to operate this grain cleaning equipment.

Request for a quote

PLANT OF AGRICULTURAL MACHINERY

Ukraine

OBC-50 is a mobile high-performance hybrid of a grain cleaning machine and a grain loader. OBC-50 can be equipped with a receiving funnel with a capacity of 2 tons of grain and a cyclone. Mobile grain cleaner OBC-50 provides grain cleaning from fine impurities on sieves and from light impurities using the built-in aspiration system. The capacity of the aspiration system in the OBC-50 is regulated depending on the type of grain being cleaned and its degree of contamination. The aspiration system can be removed and then the OBC-50 turns into a grain loader with the possibility of separating fine impurities on the sieves. Mobile grain cleaner OBC-50 produces: cleaning grain heaps of cereals, legumes, ears, cereals, sunflower, corn, soybeans, sorghum; loading grain into vehicles with a side height of up to 2 m; mechanical shoveling with simultaneous cleaning and partial drying of grain in open areas and in grain stores.

Request for a quote

PLANT OF AGRICULTURAL MACHINERY

Ukraine

The PZM-120B2 grain loader is equipped with an innovative hopper and is designed for quick loading of any transport or warehouse. The productivity of the PZM-120B2 grain loader is up to 120 tons per hour. The main innovations in the design of the hopper of the PZM-120B2 grain loader are that it consists of a main hopper 1.9 m wide and additional 2 hopper enlargers, which are installed on the right and left side walls of the main hopper in 2 minutes without the help of tools. As a result, the width and volume of the hopper increase to 3 m and 2.9 cubic meters, respectively. The innovative design of the PZM-120B2 allows its owner to: it is easy to transport PZM-120B2 even in a small trailer by jeep, minibus, etc. without the need to remove the hopper; accept grain from all types of grain carriers, trailers, big bags, front loader buckets, silos, augers, grain cleaning machines, etc. and then load it into transport or make piles of grain up to 9 m high; easy to maneuver between columns

Request for a quote

PLANT OF AGRICULTURAL MACHINERY

Ukraine

3BC-20A grain cleaning machine performs the following functions: - eliminates dust and light trash using a powerful integrated suction system; - using 16 sieves installed in the machine, it carries out high-quality cleaning of grain heaps from large and small impurities, debris, chopped grain and separates the grain into fractions. 3BC-20A is a reliable and popular grain cleaning machine, which is successfully used for cleaning cereals, legumes, oilseeds, corn, sunflower, sorghum, rape, coriander and many other crops. With the help of 3BC-20A, even very contaminated grain can be effectively cleaned to produce a quality product. 3BC-20A is a universal grain cleaning machine that can operate in three modes: in pre-treatment of grain with a capacity of up to 50 tons per hour; in primary grain cleaning mode with a capacity of up to 25 tons per hour; in the calibration mode of grain for seeds with a productivity of up to 12,5 tons per hour.

Request for a quote

SILOS SPAIN INSTALACIONES, S.L.

Spain

A galvanised corrugated steel water tank is a robust container designed to efficiently store water. Water tanks provide a practical solution to address water supply challenges and find applications across a wide range of industries, including irrigation, fire suppression, agricultural farming, and more. Our water tanks are specifically engineered to meet the demands of water storage for irrigation, catering to a variety of crops such as olives, wheat, cotton, and more. With their durable construction and effective design, these tanks ensure a reliable and convenient solution for your irrigation needs. Please note that our galvanised corrugated steel tanks are not intended for drinking water purposes. Choose our galvanised corrugated steel tanks for their durability and performance, ensuring a dependable water storage solution for your agricultural and irrigation projects.

Request for a quote

HENAN RICHI MACHINERY

United States

Richi Machinery has been committed to the research and development and production of organic fertilizer granulation equipment for many years, and is well-known at home and abroad for its high quality and high efficiency, and shines in the field of various fertilizer granules processing. Our goal is to be the leader and pioneer in the automation of organic fertilizer pellet plants. We combine solid expertise with hardware and software technologies to increase productivity and flexibility. Relying on our capabilities and experience in the automation engineering of organic fertilizer production lines and organic fertilizer production process control, we help customers reduce costs and improve efficiency, to meet different automation needs, provide comprehensive solutions and services.

Request for a quote

TOSCANO AGRICULTURAL MACHINERY

Turkey

POWER HARROW is a tillage machine with vertical blades which turn right and left continuously. The power harrow does not turnover the soil and keeps the moisture inside. Since the blades turn to the right and left, it does not hold any soil or mud. Vertical operation increases the water intake of the soil. It allows the plant roots to develop faster by preventing stratification deep in the soil. A specially adjusted blade alignment increases efficiency while reducing vibration. It prepares the seedbed, also eliminates weed and plant residue. A seeding machine connection tool makes preparing the seedbed and sowing at the same time possible. -Universal 3point CAT II Linkage -1 3/8’’ Z6 Spline PTO Protective Shaft -4 Speed; Double Outlet PTO Gearbox with 5407501000 rpm provides -2500/3000 min195 max 361 -3500/4000 min236 max437 Rotor Speed -30cm Length 15 mm thick High Quality Blades.

Request for a quoteResults for

Agriculture - machines & equipment - Import exportNumber of results

179 ProductsCountries

Company type

Category

- Agriculture - Machines & Equipment (126)

- Agricultural machines and accessories (49)

- Agricultural systems and equipment (38)

- Axles, vehicle (16)

- Irrigation systems (16)

- Milking - machinery and equipment (16)

- Spraying equipment, agricultural (14)

- Construction - Machines & Equipment (5)

- Soil preparation machinery and equipment (4)

- Agriculture and forestry - machinery and equipment (3)

- Air decontamination - machines and equipment (2)

- Farm machines (2)

- Laboratory equipment and instruments (2)

- Textiles - Machines & Equipment (2)

- Agriculture - import-export (1)

- Biomass energy - production (1)

- Construction cranes (1)

- Dosing - machines and equipment (1)

- Engines & Parts (1)

- Environmental protection - machines and equipment (1)