- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- bevel gear reducers

Results for

Bevel gear reducers - Import export

DURO DAKOVIC STROJNA OBRADA D.O.O.

Croatia

Production of different type of reducers based on yours or ours construction and technical documentations. Maintaining and repairing of reducers and other mechanical transmission parts for: - Cement industry - Steel industry - Sugar industry - Paper industry - Chemical industry

Request for a quote

PLASMA COMPANY LLC

Ukraine

A speed reducer is a mechanical device that employs gears for the purpose of reducing the speed (RPM) and increasing the torque of a motor. Usually, a speed reducer is mounted or coupled to an electric motor. An indefinite number of speed reducer options are available depending on the application. They can be sourced based on desired configurations, ratios and combinations, efficiency requirements, space limitations, cost, and rpm. Today, speed reducers are utilized in all sorts of industries. Variety of Speed Reducers and Gear Motors: - Worm gear speed reducer - Bevel gearbox speed reducer - Helical gear speed reducer - Planetary gear speed reducer

Request for a quote

DAVALL GEARS LTD.

United Kingdom

Davall DSG supply all forms of gearbox up to 150Kw

Request for a quote

XIAN HUAN-TAI TECHNOLOGY & DEVELOPMENT CO., LTD.

China

1, custom drawing 2, Materials: carbon steel, alloy steel, cast iron, cast steel, pig iron, grey iron, ductile cast iron and so on. 3, Has established efficient quality system and obtained international approvals ISO9001, TUV-PED, BV. 4, Produced by experienced technical staff. 5, Production capacity: more than 8,000MT per year. 6, Small orders accepted. 7, Perfect facilities. 8, Advanced machining equipment. 9, Material standards: GB,DIN,EN,NF,ISO,JIS,SS,BS,AISI,SAE,ASTM,UNS,ACI.

Request for a quote

EICKHOFF ANTRIEBSTECHNIK GMBH

Germany

Eickhoff gear solutions for bucket wheel excavators / stackers / reclaimers are characterised by a compact design, high adaptability and low weight. The robust gearboxes are perfectly matched to the requirements and ensure maximum availability for the mining and transport of raw materials. Our gear units are used as bucket wheel drive, travel drive or conveyor drive. When replacing existing drives, in many cases the weight can be reduced even further by increasing the performance. Advantages at a glance: — Customized solutions — Compact and weight-optimized construction — High power density — Reliable and low maintenance

Request for a quote

EICKHOFF ANTRIEBSTECHNIK GMBH

Germany

Eickhoff has been a renowned manufacturer of axle drives for rail vehicles such as locomotives and track work vehicles for more than five decades. The wheelset drives can be designed as bevel gears, spur gears or customized solutions, so that they optimally meet the performance requirements. We meet the high-quality standards in the field of transport technology thanks to our many years of experience in service and more than 2000 newly delivered final drives. Our gearboxes are robust, durable and designed for use under extreme conditions.

Request for a quote

PGR DRIVE TECHNOLOGIES

Turkey

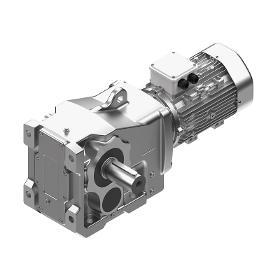

Helical bevel gear units with 90° input and output axis range. Casing with feet, flange F options. A rigid structure in case. System resistance calculations are made in accordance with ISO, DIN and NIEMANN standards. Different input options may be provided (Coupled motor, IEC, PAM, W, Servo motor connected, ...). Different output options available (Solid shaft, Hollow shaft, With shrink disc, ...).

Request for a quote

AICS BUSINESS SOLUTIONS CELIK SANAYI VE TIC. LTD. STI.

Turkey

With our extensive supplier portal, we can cover all your needs in the field of Gears and Bevel Gears. Trust us in choosing the right supplier for your needs

Request for a quote

ZWP ZAHNRADWERK PRITZWALK GMBH

Germany

ZWP is one of the leading independent manufacturer in Germany for gears, pinions and rim gears. We supply already well-known manufacturers for gear boxes. We are looking forward getting intouch with you to have a conversation about possibilities for your supply. Sectors of our (international) customers are: Mining, Oil, Offshore, rail and ship transmissions, industrial transmissions, and many more fields of applications. Overview about the capabilities for production: Gears internal and external toothed hardened and grinded Module 2 – 50 mm Diameter 100 – 2,000 mm Internal toothed rings / rim gears hardened and grinded Module up to 20 mm - more on request Diameter 100 to 1,800mm Pinions and shafts internal and external toothed hardened and grinded Module 1 – 50 mm Diameter 50 – 500 mm Length up to 1,500 mm Hardening and balancing inhouse possible Cooperation with companies for special manufacturing of gears and pinions etc We speak English.

Request for a quote

XIAN HUAN-TAI TECHNOLOGY & DEVELOPMENT CO., LTD.

China

Our company has 25 years experience for manufacture different kinds of gears.And our company has many advanced production equipments. such as CNC forming grinding wheel grinding machines, gantry machining centers, four axis and five axis machining centers, CNC lathes, CNC gear shapers, CNC milling machines, CNC hobbing machines, gear chamfering machines.and more than 40 sets of processing and testing equipment. we can provide various professional production services such as precision gear wheel machining, CNC machining, CNC turning machining, and so on.

Request for a quote

XIAN HUAN-TAI TECHNOLOGY & DEVELOPMENT CO., LTD.

China

Xian Huan-Tai has been specialized in Custom High Precision Gear, Gearbox, Gear shaft, Castings, forgings, machining parts, metal stamping parts and assembly since 1996. Material options are steel, aluminum, bronze, iron etc. We strive to provide the high quality castings and try to avoid defects delivered to our customers. Our inspection: 1.Metal testing and analysis, mechanical properties, microstructure, spectrometer and furnace chemical composition analysis. 2.Non-destruction inspection: MPE, LPE, UE and RE 3.Dimension inspection: well experienced inspector team 4.Special inspection method agreed by customers like hydraulic, gas tight test, water tight test etc.

Request for a quote

XIAN HUAN-TAI TECHNOLOGY & DEVELOPMENT CO., LTD.

China

HT spur gear bevel gear spiral gear Steel quench and tempered, bronze etc. Custom made according drawing With our specialized expertise in custom gear, gear shaft, castings parts, forging parts, machined parts, welding parts for almost three decades, we can assist you on your industrial development. Our company (Huan-Tai) is rooted in China since mid-90’s. As one of the early runners, we bring value to the table through our capabilities in engineering, quality control and schedule management that meet the high expectations of overseas customers in stability, consistency and predictability. We are proud of our core competence in industry leading production processes, spectrometer analysis, critical NDT and tight tolerance machining.

Request for a quote

XIAN HUAN-TAI TECHNOLOGY & DEVELOPMENT CO., LTD.

China

Xian Huan-Tai has been specialized in Custom High Precision Gear, Gearbox, Gear shaft, Castings, forgings, machining parts, metal stamping parts and assembly since 1996. Material options are steel, aluminum, bronze, iron etc. We strive to provide the high quality castings and try to avoid defects delivered to our customers. Our inspection: 1.Metal testing and analysis, mechanical properties, microstructure, spectrometer and furnace chemical composition analysis. 2.Non-destruction inspection: MPE, LPE, UE and RE 3.Dimension inspection: well experienced inspector team 4.Special inspection method agreed by customers like hydraulic, gas tight test, water tight test etc.

Request for a quote

XIAN HUAN-TAI TECHNOLOGY & DEVELOPMENT CO., LTD.

China

1, custom drawing 2, Materials: carbon steel, alloy steel, cast iron, cast steel, pig iron, grey iron, ductile cast iron and so on. 3, Has established efficient quality system and obtained international approvals ISO9001, TUV-PED, BV. 4, Produced by experienced technical staff. 5, Production capacity: more than 8,000MT per year. 6, Small orders accepted. 7, Perfect facilities. 8, Advanced machining equipment. 9, Material standards: GB,DIN,EN,NF,ISO,JIS,SS,BS,AISI,SAE,ASTM,UNS,ACI.

Request for a quote

ITALGEAR SRL

Italy

High quality lapped Gleason gears that exceed the expectations of the most demanding customers are well within the capability of ITALGEAR who will implement their long developed experience in the field and develop the most effective Tooth Contact Area and motion curves of the bevel gear resulting into high precision and low noise in operation. Specific software such as CAGE and Kimos are used as well as strict controls of all the production steps are applied in order to replicate precisely the mathematical model of the tooth profile (software such as GAGE and Komet are used). The use of modern Gleason Phoenix CNC gear cutting machines and Klingelnberg and Remaut CNC lapping machines with a 100% gear final check in combination with vibration analysis, allow to obtain highquality lapped Gleason gears that will satisfy the most demanding customers

Request for a quote

ITALGEAR SRL

Italy

ITALGEAR has long promoted grounding as the most effective gear finishing for Gleason bevel helical gears and takes pride in using the latest gear grinding machine from Gleason and Klingelnberg Oerlikon. The Tooth Contact Anlalisys (TCA) to obtain the optimal motion graph curves of the bevel helical gear that will generate the lowest noise and the highest precision once in operation is developed by ITALGEAR engineers through the use of specific software like CAGE and Kimos. Quality controls are performed by software’s like GAGE and Komet throughout the entire process in order to replicate precisely the mathematical model of the tooth profile.

Request for a quote

POWER JACK MOTION

China

Low Backlash: Backlash is under 3 arcmin.Backlash for 2 stage speed reduction is within 5 arcmin High Efficiency:Efficiency for 1 stage model exceeds 95%,2 stage model exceeds 92% Size:PLF060/PLF080/PLF090/PLF120/PLF160 Output Rated Torque Range:From 9Nm to 500Nm Adapter-bushing connection,can be attached to any motor No Grease Leakage and Maintenance-free Planetary Gearbox Application:Aerospace,military industry,Medical health,electronic information industry,Industrial robots,production automation,CNC machine tool manufacturing industry,Auto industry,textile,printing,food,metallurgical,environmental protection engineering,warehouse logistics industry

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

POWER JACK MOTION

China

POWER JACK MOTION considerable investment in sophisticated equipment ensures high precision, high quality, custom made Speed-Reducer Gears that adhere to tight customer specifications. We have been cutting precision Speed-Reducer Gears since 2003. Our machinery is perfect for precision gear cutting, whether it be a standard or custom design, small and large diameter gears of various dimensions and complexity.Regardless of the volume of your order, our sophisticated machines are able to get the job done quickly and effectively.

Request for a quote

DURO DAKOVIC STROJNA OBRADA D.O.O.

Croatia

In our production program there are two types of gears: straight with a maximum diameter of 4000 mm and bevel with a maximum diameter of 750 mm. Our many years of experience in the production of gears guarantees high quality gears.

Request for a quote

ERKAS MACHINE AND GEAR INDUSTRY

Turkey

ERKAS Machine and gear manufacturing of bevel gear in turkey, since 1989

Request for a quote

ERKAS MACHINE AND GEAR INDUSTRY

Turkey

ERKAS Machine supplier of spur gear, helical gear, bevel gear, rack gear in Turkey since 1989

Request for a quote

EICKHOFF ANTRIEBSTECHNIK GMBH

Germany

Eickhoff planetary gearboxes are ideal for driving large industrial plants. With our roller press gears of the new ED series we cover a wide torque range from 220kNm up to more than 7,000kNm. The special non-contact sealing system also makes our gearboxes very low maintenance. Convince yourself of the efficiency of our roller press gears, which are used for the crushing and grinding of raw materials. If necessary, we will adapt the gearbox to your requirements and develop the entire drive concept together with you. All our gearboxes can be equipped with an additional sensor system, which enables a permanent monitoring of the operating status. This allows operation-relevant risks to be detected at an early stage in order to counteract a possible unexpected machine failure. Advantages at a glance: — Compact design with highest power density — Reliable and low maintenance — Flexible design variants and accessories — Large capacity range

Request for a quote

KAR LTD

Turkey

For your machines we develop gear, you can tell us your machine and we can produce..

Request for a quote

EICKHOFF ANTRIEBSTECHNIK GMBH

Germany

Eickhoff offers application-specific solutions for winch systems in the field of lifting and conveyor technology. Even torques of over 2500 kNm are no problem. Our planetary gearboxes are characterised by a compact design and high power density, which is particularly advantageous in space-critical fields of application such as the maritime sector. The direct integration of our gearboxes into the rope drums can be realised individually. Due to the high efficiency of the planetary and spur gear units, they operate with extremely low losses. Based on our modular system, solutions can be derived individually adapted to the respective application. Advantages at a glance: — Compact design — High efficiency — Reliable and low maintenance — Customized solution

Request for a quote

EICKHOFF ANTRIEBSTECHNIK GMBH

Germany

Sophisticated drive concepts for ball mills and rotary kilns require powerful solutions. Eickhoff offers different gear solutions for the various drive concepts established in the field, such as side drive, central drive and direct drive. In addition to the robust Eickhoff helical gearboxes, our ED planetary gearboxes are preferred, especially for a central drive. They offer a compact solution with extremely high power density and are therefore also leading from an economic point of view. Even torques of over 7,000 kNm can be realised. Typical applications are the crushing of raw materials as well as the burning of cement clinker. The gears are characterised by a long service life and high power density.

Request for a quoteResults for

Bevel gear reducers - Import exportNumber of results

26 ProductsCompany type

Category

- Gears (18)

- Reducers (2)

- Reducing gears, hydraulic (2)

- Gearboxes for vehicles (1)

- Handling - Machines & Equipment (1)

- Iron, steel and metallurgy - import-export (1)

- Metal cutlery (1)

- Milling - steels and metals (1)

- Moto-reducers (1)

- Speed variators and reducers (1)

- Tools & Hardware (1)

- Welding, electric - equipment and supplies (1)