- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- biomass plants

Results for

Biomass plants - Import export

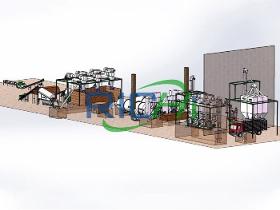

HENAN RICHI MACHINERY

United States

RICHI is mainly engaged in the research and development, manufacturing of biomass pellet mills,also specializes in biomass pellet mill for sale. Our biomass pellet mill can be used to process all kinds of agricultural and forestry waste pellets (wood, straw, hay, grass, rice husk, efb bamboo, bagasse, peanut shell…). RICHI biomass pellet mill is designed with high quality, environmental protection and intensification. It can produce bio pellets that meet the high quality pellets standard of different countries, ideal for biomass pellet manufacturers.

Request for a quote

PHARMA HERBS

Croatia

The CBD hemp biomass refers to the whole hemp plant. The hemp biomass can be used for the production of a variety of products such as food, hemp fuels and energy, hemp oils and hemp fibre. For many years, numerous studies have been conducted regarding the hemp plant. This versatile plant can be used in almost all aspects of human life. In the food industry, in the medical sector and as a biofuel which is a good source of renewable energy. The CBD hemp biomass has been used for centuries for different purposes. It can be used for the making medicine, food (from the seeds and oils), and beauty products such as hemp oils and for the production of fibre and fabrics

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

FOR VARIOUS INDUSTRIES AND A VARIETY OF APPLICATIONS LIPP bulk silos are being used from a variety of industries and companies for different applications. Since decades, LIPP silos are used for the storage of grain in flower mills or as storage for animal feed in the agricultural sector. Also the furniture and wood industry is using LIPP silos to store wood chips or saw dust. ADVANTAGES OF LIPP BULK STORAGE A growing application is the storage of pallets for biomass plants. Different manufacturing companies are using LIPP bulk material silos as storage of buffer for their raw materials. The enhanced stability coming from the Double Fold System allows to construction of silos with big diameter and height ratio, with free carrying roofs as well as a fast filling and extraction. The silos can be built in closed manufacturing halls or building, very narrow installation sites and on high steel or concrete structures.

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

The LIPP® Large Thermal Storage Tank is a customized solution to effectively store excessive heat from biogas plants, biomass heating plants, solar plants or other heat sources. The carbon steel tanks are fabricated on site with the patented automated LIPP® Welding Technology. The horizontal welding process enables the infinitely variable production of tanks up to 6,000 m³ volume with horizontal welding only. The largevolume, above ground storage tanks are fitted with all necessary safety and operation equipment. Additional, individual components according to client’s specification can be considered. The roof and wall insulation is individually adapted to local conditions. The LIPP® Thermal Storage Tanks operate at atmospheric pressure, at a temperature of up to 95° C and are suitable for use with heating water. Speciality No additional nitrogen system necessary.

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

CONTAINER AND SYSTEM SOLUTIONS FOR THE INTERMEDIATE STORAGE OF HEAT FROM WASTE HEAT OR RENEWABLE ENERGIES The intermediate storage of heat from biogas plants, biomass cogeneration plants or other heat sources is an important prerequisite for effective use. Lipp buffer tank systems are economic system solutions for the storage and supply of thermal energy and can be easily integrated into customised solutions for local heat supply. LIPP BUFFER STORAGE TANKS The individually tailored solution appropriate to heat storage requirements with useful volumes of 80 to 3,000 m³ is made of stainless steel with the Lipp dual seam system and operated in conjunction with insulation adjusted to the application at about 95 ° C. Since the Lipp system is unpressurised, the container solutions are extremely low maintenance and are very durable. The high volume, above ground Lipp storage tanks have been specially developed for this application and are popular with end users and energy suppliers alike.

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

SOLUTION TO EFFECTIVELY STORE EXCESSIVE HEAT FROM BIOGAS PLANTS – FROM 2,000 TO 6,000 M³ The LIPP® Thermal Storage Tank is a customized solution to effectively store excessive heat from biogas plants, biomass heating plants, solar plants or other heat sources. The carbon steel tanks are fabricated on site with the patented automated LIPP® Welding Technology. The horizontal MAW welding process enables the infinitely variable production of tanks up to 6,000 m³ volume with horizontal welding only. The large volume, above ground storage tanks are fitted with all necessary safety and operation equipment. Additional, individual components according to client’s specification can be considered. The roof and wall insulation is individually adapted to local conditions. The LIPP® Thermal Storage Tanks operate at atmospheric pressure, at a temperature of up to 95° C and are suitable for use with heating water. No additional nitrogen system necessary.

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

FOR THE INTERMEDIATE STORAGE OF RENEWABLE ENERGIES – FROM 200 TO 2,000 M³ The LIPP® thermal storage tank is the tailored thermal storage solution for renewable energies with an effective volume ranging from 200 to 2,000 m3 which is suitable for individual customisation. Expedient thermal storage is a prerequisite for the effective utilisation of heat from biogas plants, biomass cogeneration plants, solar plants or other heat sources. The flexible capacity LIPP® buffer storage tank provides the ideal solution for this application. The tanks are fabricated on site using the tried and tested LIPP® Double Seam System and the stainless steel VERINOX®. Insulation can be tailored to the intended application in order to produce large volume, above ground storage tanks with an individually customised interior. The tanks are designed for non pressurised operation with an operating temperature of up to 95 °C and are suitable for use with heating water. No additional nitrogen system necessary.

Request for a quote

VERMILION DIS TICARET LIMITED SIRKETI

Turkey

Our single-use tableware products (plates, bowls, cups, boxes) are biologically and compostably self-degradable in nature, made from renewable sugarcane fibers. 0% Plastic – A Healthy Choice 100% plant biomass without any glue, lining, adhesive, laminate, or coating. Completely natural, dissolves in nature within 60 to 90 days. Vermilion tableware doesn't involve cutting down trees. Raw material obtained from plant fibers after industrial processing. Liquid & oil-resistant. Resistant to 100 degrees Celsius water and 120 degrees Celsius oil. Doesn't bend or break. Does not alter the taste of food. Microwave-safe. All products carry the 'food contact safe' sign. Hygienic. Can be safely used in a microwave, heater, or oven, and is resistant to temperatures between -20°C and +150°C

Request for a quote

VERMILION DIS TICARET LIMITED SIRKETI

Turkey

Our single-use tableware products (plates, bowls, cups, boxes) are biologically and compostably self-degradable in nature, made from renewable sugarcane fibers. 0% Plastic – A Healthy Choice 100% plant biomass without any glue, lining, adhesive, laminate, or coating. Completely natural, dissolves in nature within 60 to 90 days. Vermilion tableware doesn't involve cutting down trees. Raw material obtained from plant fibers after industrial processing. Liquid & oil-resistant. Resistant to 100 degrees Celsius water and 120 degrees Celsius oil. Doesn't bend or break. Does not alter the taste of food. Microwave-safe. All products carry the 'food contact safe' sign. Hygienic. Can be safely used in a microwave, heater, or oven, and is resistant to temperatures between -20°C and +150°C.

Request for a quote

VERMILION DIS TICARET LIMITED SIRKETI

Turkey

Our single-use tableware products (plates, bowls, cups, boxes) are biologically and compostably self-degradable in nature, made from renewable sugarcane fibers. 0% Plastic – A Healthy Choice 100% plant biomass without any glue, lining, adhesive, laminate, or coating. Completely natural, dissolves in nature within 60 to 90 days. Vermilion tableware doesn't involve cutting down trees. Raw material obtained from plant fibers after industrial processing. Liquid & oil-resistant. Resistant to 100 degrees Celsius water and 120 degrees Celsius oil. Doesn't bend or break. Does not alter the taste of food. Microwave-safe. All products carry the 'food contact safe' sign. Hygienic. Can be safely used in a microwave, heater, or oven, and is resistant to temperatures between -20°C and +150°C.

Request for a quote

VERMILION DIS TICARET LIMITED SIRKETI

Turkey

Our single-use tableware products (plates, bowls, cups, boxes) are biologically and compostably self-degradable in nature, made from renewable sugarcane fibers. 0% Plastic – A Healthy Choice 100% plant biomass without any glue, lining, adhesive, laminate, or coating. Completely natural, dissolves in nature within 60 to 90 days. Vermilion tableware doesn't involve cutting down trees. Raw material obtained from plant fibers after industrial processing. Liquid & oil-resistant. Resistant to 100 degrees Celsius water and 120 degrees Celsius oil. Doesn't bend or break. Does not alter the taste of food. Microwave-safe. All products carry the 'food contact safe' sign. Hygienic. Can be safely used in a microwave, heater, or oven, and is resistant to temperatures between -20°C and +150°C.

Request for a quote

VERMILION DIS TICARET LIMITED SIRKETI

Turkey

Our single-use tableware products (plates, bowls, cups, boxes) are biologically and compostably self-degradable in nature, made from renewable sugarcane fibers. 0% Plastic – A Healthy Choice 100% plant biomass without any glue, lining, adhesive, laminate, or coating. Completely natural, dissolves in nature within 60 to 90 days. Vermilion tableware doesn't involve cutting down trees. Raw material obtained from plant fibers after industrial processing. Liquid & oil-resistant. Resistant to 100 degrees Celsius water and 120 degrees Celsius oil. Doesn't bend or break. Does not alter the taste of food. Microwave-safe. All products carry the 'food contact safe' sign. Hygienic. Can be safely used in a microwave, heater, or oven, and is resistant to temperatures between -20°C and +150°C.

Request for a quote

VERMILION DIS TICARET LIMITED SIRKETI

Turkey

Our single-use tableware products (plates, bowls, cups, boxes) are biologically and compostably self-degradable in nature, made from renewable sugarcane fibers. 0% Plastic – A Healthy Choice 100% plant biomass without any glue, lining, adhesive, laminate, or coating. Completely natural, dissolves in nature within 60 to 90 days. Vermilion tableware doesn't involve cutting down trees. Raw material obtained from plant fibers after industrial processing. Liquid & oil-resistant. Resistant to 100 degrees Celsius water and 120 degrees Celsius oil. Doesn't bend or break. Does not alter the taste of food. Microwave-safe. All products carry the 'food contact safe' sign. Hygienic. Can be safely used in a microwave, heater, or oven, and is resistant to temperatures between -20°C and +150°C.

Request for a quote

VERMILION DIS TICARET LIMITED SIRKETI

Turkey

Our single-use tableware products (plates, bowls, cups, boxes) are biologically and compostably self-degradable in nature, made from renewable sugarcane fibers. 0% Plastic – A Healthy Choice 100% plant biomass without any glue, lining, adhesive, laminate, or coating. Completely natural, dissolves in nature within 60 to 90 days. Vermilion tableware doesn't involve cutting down trees. Raw material obtained from plant fibers after industrial processing. Liquid & oil-resistant. Resistant to 100 degrees Celsius water and 120 degrees Celsius oil. Doesn't bend or break. Does not alter the taste of food. Microwave-safe. All products carry the 'food contact safe' sign. Hygienic. Can be safely used in a microwave, heater, or oven, and is resistant to temperatures between -20°C and +150°C.

Request for a quote

VERMILION DIS TICARET LIMITED SIRKETI

Turkey

Our single-use tableware products (plates, bowls, cups, boxes) are biologically and compostably self-degradable in nature, made from renewable sugarcane fibers. 0% Plastic – A Healthy Choice 100% plant biomass without any glue, lining, adhesive, laminate, or coating. Completely natural, dissolves in nature within 60 to 90 days. Vermilion tableware doesn't involve cutting down trees. Raw material obtained from plant fibers after industrial processing. Liquid & oil-resistant. Resistant to 100 degrees Celsius water and 120 degrees Celsius oil. Doesn't bend or break. Does not alter the taste of food. Microwave-safe. All products carry the 'food contact safe' sign. Hygienic. Can be safely used in a microwave, heater, or oven, and is resistant to temperatures between -20°C and +150°C.

Request for a quote

VERMILION DIS TICARET LIMITED SIRKETI

Turkey

Our single-use tableware products (plates, bowls, cups, boxes) are biologically and compostably self-degradable in nature, made from renewable sugarcane fibers. 0% Plastic – A Healthy Choice 100% plant biomass without any glue, lining, adhesive, laminate, or coating. Completely natural, dissolves in nature within 60 to 90 days. Vermilion tableware doesn't involve cutting down trees. Raw material obtained from plant fibers after industrial processing. Liquid & oil-resistant. Resistant to 100 degrees Celsius water and 120 degrees Celsius oil. Doesn't bend or break. Does not alter the taste of food. Microwave-safe. All products carry the 'food contact safe' sign. Hygienic. Can be safely used in a microwave, heater, or oven, and is resistant to temperatures between -20°C and +150°C.

Request for a quote

VERMILION DIS TICARET LIMITED SIRKETI

Turkey

Our single-use tableware products (plates, bowls, cups, boxes) are biologically and compostably self-degradable in nature, made from renewable sugarcane fibers. 0% Plastic – A Healthy Choice 100% plant biomass without any glue, lining, adhesive, laminate, or coating. Completely natural, dissolves in nature within 60 to 90 days. Vermilion tableware doesn't involve cutting down trees. Raw material obtained from plant fibers after industrial processing. Liquid & oil-resistant. Resistant to 100 degrees Celsius water and 120 degrees Celsius oil. Doesn't bend or break. Does not alter the taste of food. Microwave-safe. All products carry the 'food contact safe' sign. Hygienic. Can be safely used in a microwave, heater, or oven, and is resistant to temperatures between -20°C and +150°C.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

AKROMAK METAL DIŞ TIC. LTD. ŞTI.

Turkey

Air cooled grate bar, as cast, 75 mm wide, Roststab, without air outlet slots, material: heat resistant steel casting 1.4777 GX130CrSi29

Request for a quote

AKROMAK METAL DIŞ TIC. LTD. ŞTI.

Turkey

Air cooled grate bar, as cast, 99,2 mm wide, Roststab, with air outlet slots, material: heat resistant steel casting 1.4777 GX130CrSi29

Request for a quote

AKROMAK METAL DIŞ TIC. LTD. ŞTI.

Turkey

Air cooled grate bar, machined, 132,5 and 137,5 mm wide, Roststab, without air outlet slots, material: heat resistant steel casting 1.4823 GX40CrNiSi27-4

Request for a quote

HENAN RICHI MACHINERY

United States

Capacity: 0.3-4.5T/H (Single Machine), 0.3-90 T/H (Full System) Application: Biomass Pellet Plant, Wood Pellet Factory, Fuel Pellet Plant, Lumber Factory, Furniture Factory, Pine Cat Litter Factory, Etc. The raw materials of RICHI wood chip press machine come from a wide range of sources, including chips, sawdust, shavings, bark, sanding powder, waste wood log, and branches produced in wood processing and wood-based panel production. Various types of straw produced after crop harvest and other types combustible biomass can also be used as raw material, without adding any adhesive, and wood pellet fuel can be produced through equipment processing.

Request for a quote

RIPPERT ANLAGENTECHNIK GMBH & CO. KG

Germany

Heating technology with a future The calculation is simple, the technology successful. Efficient surface drying is achieved with biomass in Rippert plants. Together with the Hargassner company from Austria, a specialist for heating with biomass, and the proven Rippert plant know-how, the technology is now marketable and has gone into production. The demanding drying characteristics in a powder-coating plant are compatible with the process and work perfectly. A future-orientated heating technology with considerable economic and ecological benefits – the experts are unanimous in that. Wood pellets or wood chips are the inexpensive energy suppliers. They are valuable waste products that result from the processing of domestic timbers. Heating with wood chips – without intermediate heat transfer media such as thermal oil • Environmentally friendly and CO2-neutral • fully automatic boiler cleaning and ash discharge Maximum financial saving potentials are realised with this energy carrier. Wood chips, chopped to a transportable size and dried by the supplier, are stored in the storeroom near the plant. It can be located on the same level or lower. A tried-and tested transport system consisting of a floor agitator with springs and discharge auger carries the wood chips reliably into the plant. Here it acts as a fuel with maximum convenience. If the calorific value equivalents are examined, we see that 1,000 litres of fuel oil is equivalent to 12 m³ of wood chips. The ratio is the same for 1,000 m³ of natural gas. Heating with wood pellets - without intermediate heat transfer media such as thermal oil Wood pellets are true energy bundles. They consist of natural wood and are made by compressing sawdust, which is produced in large quantities every day in the industry. As a biomass they are the alternative to wood chips and are just as advantageous from an economical point of view. Pellets have the smallest volume and are conveyed dust-free and without odours from storage containers to a storage vessel next to the plant. They are transported into the combustion chamber via a rotary vane feeder and feed auger. For comparison: 1,000 l fuel oil = 2 t pellets 1,000 m³ natural gas = 2 t pellets 1,000 l liquefied gas = 1.32 t pellets Advantages • Reduction in energy costs Heating cost comparison (reference = 1,000 l fuel oil)

Request for a quote

DE SMET ENGINEERS & CONTRACTORS

Belgium

DSEC is your trusted partner for the construction of your biomass energy plants. Biomass to energy via cogeneration is a sustainable power source, its valorisation can be done trough many different processes. The choice for the suitable technology depends on its various characteristics (moisture, size, ashes melting point, chlorine content, ashes content, ...). Several applications can be developed, from heat production to power generation or even combined heat and power plant. Through its numerous references in biomass valorization, DSEC is able to provide the right expertise to the customer. De Smet Engineers & Contractors is an actor into the green heat and electricity field, developing realizations from concept to start-up. Thanks to our wide turnkey experience, we may give warranties on the schedule, the investment and the performances. Developed biomass energy via cogeneration projects concern pellet production, biomethanisation, wood chips gasification, straw combustion, sunflower husks, bagasse and other agricultural residues valorization for direct steam production or electricity production with back pressure or condensing turbine. De Smet Engineers and Contractors offers you turnkey solutions fitting with your specific needs, that can start with Conceptual Engineering and FEED studies and finally evolve into a Full EPC biomass energy plant project.

Request for a quote

MTK LTD

Russia

Most of the mushroom species are honey plants. Camelina oil is made from the seeds of the camelina. Plant biomass can be used as feedstock for the production of second generation biofuels.

Request for a quote

J.D.F. IMPORT-EXPORT GMBH

Germany

Application Others (Biomass Power Plant) Density 700 kg/m3 Diameter 6 - 8mm Shape Stick Length Custom Calory (J) 4100-4600 Moisture (%) <10

Request for a quote

SCHALLER MESSTECHNIK GMBH

Austria

The humimeter BM2 biomass moisture meter measures the water content of various kinds of biomass and is ideal for operators of biomass heating plants. The bulk density compensation ensures accurate and reliable results. The BM2 biomass moisture meter can be used for the determination of water content of wood chips, bark, wood pellets, elephant grass, wood shavings, sawdust and maize cobs. Handling / Measuring procedure Place the empty measuring device on the scale and fill the supplied 13 liter bucket with the material to measure. Constantly fill the material into the measuring chamber and select the right calibration curve. The humimeter BM2 biomass moisture meter instantly displays the water content. If required the measuring value can be saved on the device or sent to your PC via supplied USB cable. + high accuracy due to high sample volume of 13 liters + bulk density compensated + quick measuring results + wide range of calibration curves + customer calibration function

Request for a quote

SCHALLER MESSTECHNIK GMBH

Austria

Professional moisture meter for determining the water content of biomass with optional display of bulk density and bone dry weight (tons/m³) For suppliers and operators of biomass heating plants, for measuring wood chips, barks, wooden pellets, elephant grass, wood shavings, sawdust and maize cobs Your benefits: + High measuring range up to 70% water content (dependent on the material) + Bulk density compensation by integrated scale + Display of bulk density and ATRO tons/m³ + measurement within seconds without prior treatment of sample + quick and fully automated measuring procedure + outstanding accuracy due to high sample volume + bulk density compensated + wide range of calibration curves

Request for a quote

OFFICINE CONTERNO SRL

Italy

We produce transportation and storage plants for any type of bulk material: from aggregates, to plant biomass waste, cereals, up to milling and food. Conveyor belts with rubber mats, metal plate conveyors, redlers, bucket elevators, screw conveyors, silos and hoppers of various shapes and capacities. With the experience gained over the years, we can design and construct conveyors for the most demanding applications such as waste from differentiated MSW collection, RDF and ash from incinerators, as well as for m ore traditional uses such as the transportation of sands or gravels.

Request for a quote

BESTON MACHINERY

China

In today's society, there is an increased center on alternative energy sources and sustainable practices. The best way to contribute to this effort is to apply a biomass carbonization machine. This machine turns organic waste into biochar, which can be used as a soil amendment or fuel source. By using a biomass carbonization machine, you are able to help make your business more sustainable and minimize your environmental impact.

Request for a quoteResults for

Biomass plants - Import exportNumber of results

31 ProductsCountries

Category

- Food packaging (11)

- Tanks, metal (4)

- Biomass energy - production (3)

- Casting, steel (3)

- Measurement - Equipment & Instruments (2)

- Agriculture - Machines & Equipment (1)

- Cardboard - disposable tableware and articles (1)

- Charcoal (1)

- Herbs for medicines and cosmetics (1)

- Oilseed crops (1)

- Storage tanks (1)

- Wood veneer - machinery and equipment (1)